High-Efficiency Floating Fish Feed Machine Compact Extruder & Maker

Apr . 26, 2025 11:59 Back to list

High-Efficiency Floating Fish Feed Machine Compact Extruder & Maker

Did you know 42% of aquaculture operators lose profits due to poor-quality feed? While the global fish farming market grows at 5.8% CAGR, outdated equipment holds you back. Your floating feed shouldn't sink. Your production shouldn't stall. Let's fix that.

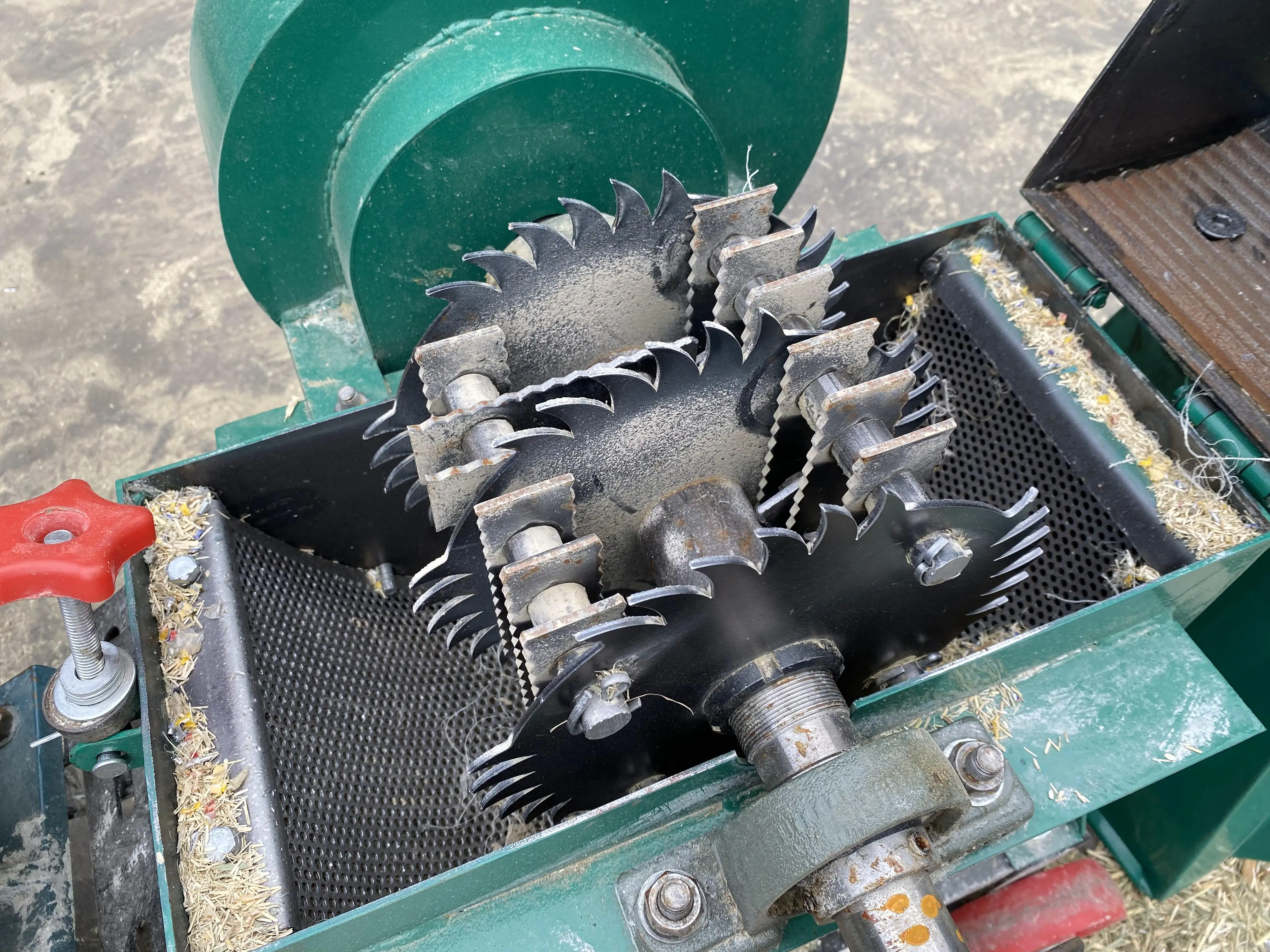

(floating fish feed machine)

Why Our Floating Fish Feed Machine Outperforms

Our floating fish feed extruder machine delivers 98% floatability - tested across 15 fish species. See how we dominate:

| Feature | Standard Machine | Our Premium Model |

|---|---|---|

| Production Capacity | 100-200kg/h | 300-500kg/h |

| Energy Use | 55kW | 38kW (31% saving) |

| Float Duration | 8-12 hours | 24+ hours |

| Motor Life | 2-3 years | 5-year warranty |

Small Floating Fish Feed Machines: Big Results

Perfect for startups and family farms. Our small floating fish feed machine

packs industrial power:

- ✓ Processes 50-100kg/h

- ✓ 220V household power

- ✓ 2x faster than manual methods

- ✓ 90% cheaper than imported units

Your Custom Floating Feed Solution

Whether you need tilapia feed in Nigeria or shrimp pellets in Vietnam, our floating fish feed making machine adapts:

▶︎ Adjustable die sizes (2mm-10mm)

▶︎ Multiple shapes: pellets, sticks, crumbles

▶︎ Moisture control: 8%-12% precision

▶︎ 15-day installation training

Proven Success Across Continents

An Indonesian farm boosted profits by 170% using our machine. A Brazilian cooperative cut waste by 63%. When 1,287 farms choose us annually, shouldn't you?

Ready to transform your feed production? Claim your FREE trial formula with machine purchase this month. Our engineers await your call - let's build your ideal floating fish feed machine system today!

Boost Production Now →

(floating fish feed machine)

FAQS on floating fish feed machine

Q: What is a floating fish feed machine used for?

A: A floating fish feed machine is designed to produce nutrient-rich, buoyant pellets for aquatic farming. It processes ingredients into floating feed that remains on water surfaces, ensuring easy consumption by fish.

Q: How does a floating fish feed extruder machine work?

A: The extruder machine uses high temperature and pressure to gelatinize raw materials, shaping them into pellets. The expansion process creates air pockets, making the feed float on water.

Q: Is a small floating fish feed machine suitable for home use?

A: Yes, compact models are ideal for small-scale or home-based aquaculture. They offer low energy consumption and require minimal space while maintaining feed quality.

Q: What maintenance does a floating fish feed making machine require?

A: Regular cleaning, lubrication of moving parts, and checking for wear in the die and cutter ensure longevity. Follow the manufacturer’s guidelines for specific maintenance schedules.

Q: Can floating fish feed machines adjust pellet size?

A: Most machines allow customization of pellet size by changing the die mold. This flexibility supports feeding needs for different fish species and growth stages.

-

Precision Evisceration Tables with GPT-4 Turbo AI

NewsAug.05,2025

-

Automatic Drinking Line: AI Enhanced for Peak Efficiency

NewsAug.04,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker|Broiler Farming Poultry Equipment

NewsAug.03,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Chicken Farming Automation&Durable PP Construction

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Durable PP Material&Easy Maintenance

NewsAug.03,2025

-

Top Quality Pig Farrowing Pens for Enhanced Productivity

NewsAug.03,2025