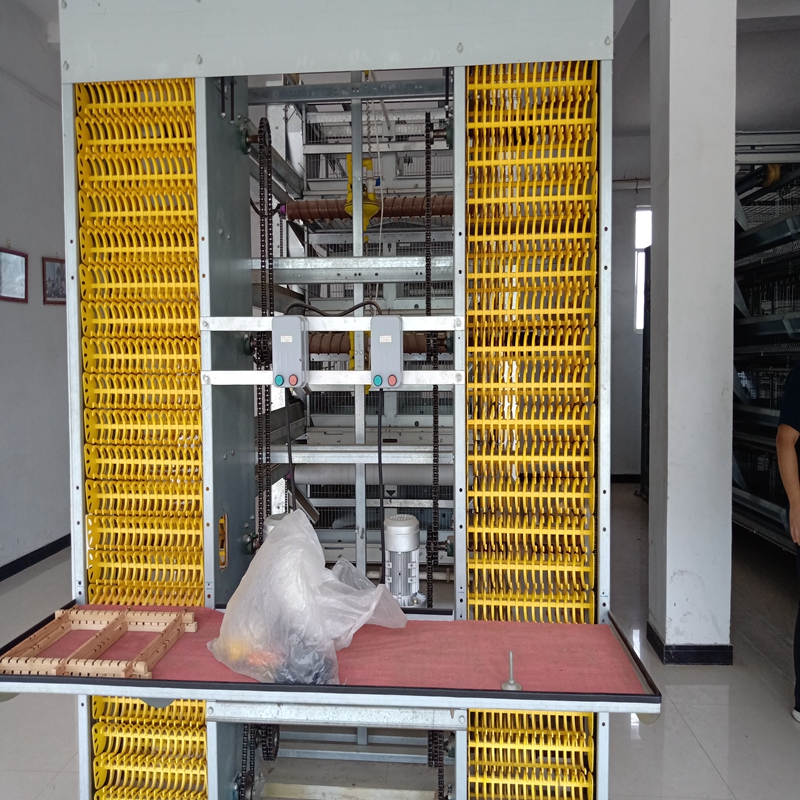

cross cutting machine

Dec . 04, 2024 18:16 Back to list

cross cutting machine

The Functionality and Importance of Cross-Cutting Machines in Modern Manufacturing

In the realm of modern manufacturing, efficiency and precision are paramount. Among the array of tools and machines that facilitate these qualities, the cross-cutting machine stands out as a crucial piece of equipment, especially in the timber and textile industries. This article delves into the functionality, benefits, and applications of cross-cutting machines, emphasizing their role in enhancing productivity and ensuring quality in manufacturing processes.

What is a Cross-Cutting Machine?

A cross-cutting machine is specifically designed for the accurate cutting of materials across their grain or length, facilitating operations that require pieces of specific dimensions or shapes. These machines are equipped with advanced technology that allows them to handle various materials, including wood, plastic, and metals. The cutting process typically involves a rotating blade that moves horizontally to slice through the material, ensuring clean and precise cuts.

Key Features

1. Precision Cutting One of the most significant advantages of cross-cutting machines is their ability to provide high precision in cuts. Advanced models are equipped with digital measuring systems that allow operators to input exact measurements, ensuring consistency in output.

2. Versatility Cross-cutting machines can efficiently cut various materials, making them suitable for multiple industries, including woodworking, construction, and manufacturing. This versatility allows businesses to utilize a single machine for several applications, thus reducing the need for multiple equipment types.

3. Speed and Efficiency With automation and advanced features, cross-cutting machines significantly reduce the time needed for cutting processes. Operators can produce large volumes of cuts in a fraction of the time it would take with manual methods, leading to increased overall productivity.

4. Enhanced Safety Features Modern cross-cutting machines are designed with operator safety in mind. Features such as emergency stop buttons, automatic blade guards, and advanced sensors help mitigate risks associated with cutting operations, ensuring a safer workplace.

Applications

Cross-cutting machines are used extensively across various sectors

cross cutting machine

- Woodworking Industry In woodworking, these machines are essential for producing components used in furniture, cabinetry, and flooring. The ability to make precise cuts ensures that pieces fit together seamlessly, enhancing the quality of the final product.

- Construction In the construction industry, cross-cutting machines are crucial for cutting lumber and panels to required dimensions. This process is important for framing structures and creating custom fittings, ensuring both accuracy and efficiency.

- Manufacturing Various manufacturing sectors use cross-cutting machines to prepare raw materials for assembly. Whether it’s plastics, metals, or composites, the ability to quickly and accurately cut materials is vital to maintaining production flow.

Advantages of Cross-Cutting Machines

Employing cross-cutting machines in manufacturing processes offers numerous advantages

- Cost Efficiency By improving cutting speed and reducing waste due to inaccuracies, companies can significantly cut production costs.

- Quality Assurance Consistent and precise cuts contribute to better product quality, reducing errors and the need for rework.

- Improved Lead Times Faster processing of materials means shorter lead times, allowing companies to respond more quickly to market demands and customer preferences.

Conclusion

In conclusion, cross-cutting machines play an invaluable role in enhancing the efficiency and precision of manufacturing processes across various industries. Their ability to provide high-quality cuts quickly and safely makes them a cornerstone of modern manufacturing practices. As industries continue to evolve and demand greater efficiency, the significance of cross-cutting machines will only increase, solidifying their position as essential tools in the manufacturing landscape. Investing in advanced cross-cutting technology is thus a strategic move for any business looking to thrive in today's competitive environment.

-

High Performance Exhaust Fan – Efficient Ventilation Solutions for Home

NewsJun.10,2025

-

High-Quality Gestation Pen for Sows Durable Mobile Pig Pen & Simple Pig Pen Solutions

NewsJun.10,2025

-

High Quality Rabbit Cage Double Tier Designs & Welded Wire Mesh Supplier

NewsJun.10,2025

-

Floating Fish Feed Machine - High Efficiency Floating Fish Feed Extruder for Small Scale Production

NewsJun.10,2025

-

Premium Poultry Housing Solutions Mobile & Commercial Free Range Options

NewsJun.10,2025

-

Industrial FRP Fans Corrosion-Resistant Blades & Centrifugal Systems

NewsJun.09,2025