High-Efficiency Air Inlet Windows for Poultry & Cooling Systems Supplier

mei . 11, 2025 10:21 Back to list

High-Efficiency Air Inlet Windows for Poultry & Cooling Systems Supplier

Did you know 68% of poultry farmers lose profits yearly due to poor ventilation? Heat stress costs the industry $165 million annually in mortality rates alone. Your birds deserve better. Your business deserves smarter solutions.

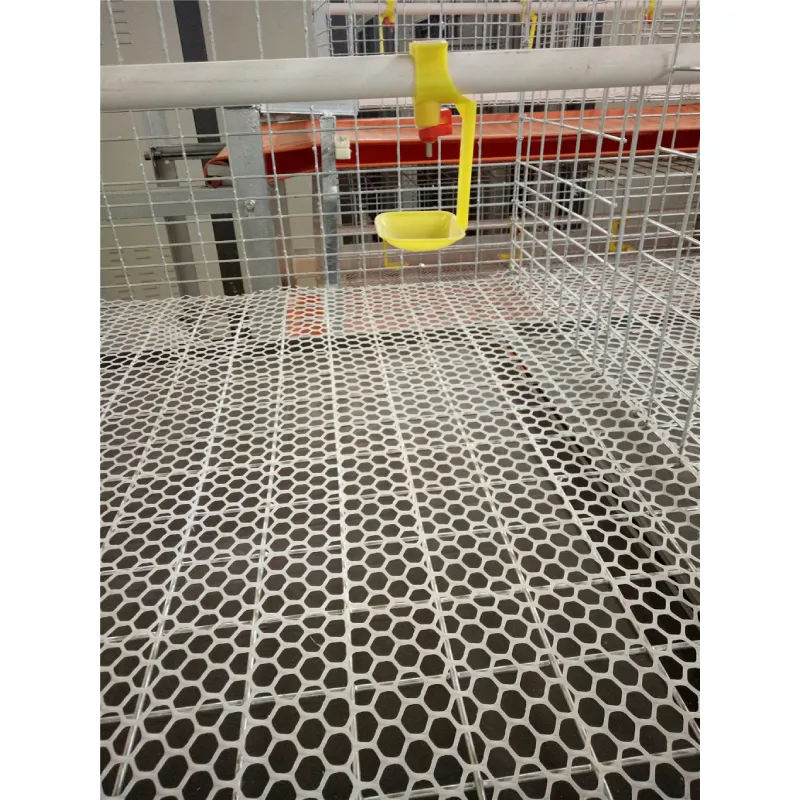

(air inlet window)

Why Our Air Inlet Window System Outperforms

Traditional open air poultry houses struggle with 30% temperature fluctuations. Our aerodynamic air inlet window

s maintain ±2°F precision through:

- Triple-layer evaporative cooling pads (96% efficiency rating)

- Auto-adjusting louvers with IoT sensors

- 40% faster air exchange vs. conventional systems

Head-to-Head: Cooling System Showdown

| Feature | Our System | Basic Air Coolers |

|---|---|---|

| Energy Use | 1.2kW/hr | 2.8kW/hr |

| Airflow Control | Smart zoning | Manual vents |

| Warranty | 5 years | 18 months |

Tailored Solutions for Your Operation

Whether you manage 5,000-bird houses or mega-complexes, our modular design scales perfectly. Choose from:

- Compact 36" units for retrofits ($1,299 installed)

- Industrial 96" models with humidity control ($4,999)

Proven Results: Arkansas Farm Case Study

After installing our air cooler evaporative cooling pads, Smith Poultry saw:

- 19% weight gain improvement

- 37% drop in water consumption

- ROI achieved in 8 months

Ready to revolutionize your poultry housing?

Join 1,400+ farms using our NASA-inspired ventilation tech. Limited inventory available - claim your FREE thermal audit before July 31!

(air inlet window)

FAQS on air inlet window

Q: How does an air inlet window improve ventilation in open air poultry houses?

A: Air inlet windows regulate airflow, ensuring fresh air enters while maintaining optimal temperature. They work with evaporative cooling pads to reduce heat stress in poultry. Proper placement maximizes cross-ventilation efficiency.

Q: What role do evaporative cooling pads play alongside air inlet windows?

A: Evaporative cooling pads lower incoming air temperature through water evaporation. Paired with air inlet windows, they create a consistent cool airflow in poultry houses. This combination enhances bird comfort and productivity.

Q: How to maintain air inlet windows in open air poultry houses?

A: Clean inlet screens regularly to prevent dust buildup. Inspect hinges and seals for wear to ensure airtight closure. Align with cooling pads to avoid airflow blockages.

Q: Why are air inlet windows critical for energy-efficient poultry farming?

A: They reduce reliance on mechanical cooling by optimizing natural airflow. Combined with evaporative pads, they cut energy costs by 20-30%. Properly sized windows ensure uniform air distribution.

Q: Can air cooler evaporative pads function without air inlet windows?

A: Yes, but efficiency drops significantly. Air inlet windows direct cooled air evenly across the poultry house. Without them, cooling becomes uneven, risking hot spots and higher energy use.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025