Efficient Vacuum Skin Packaging Solutions for Enhanced Food Freshness and Shelf Life

Oct . 17, 2024 17:37 Back to list

Efficient Vacuum Skin Packaging Solutions for Enhanced Food Freshness and Shelf Life

Understanding Vacuum Skin Packaging Machines

In the dynamic realm of food packaging, advancements in technology have led to innovative solutions that not only enhance the shelf life of products but also improve their presentation. One such revolutionary technique is Vacuum Skin Packaging (VSP). At the heart of this technology lies the vacuum skin packaging machine, a device instrumental in preserving food by creating a perfect fit between the product and its packaging.

What is Vacuum Skin Packaging?

Vacuum skin packaging is a modern packaging method that involves sealing food products tightly in a specially designed plastic film, thus removing oxygen and air. This process significantly reduces the potential for microbial growth while maintaining the quality and freshness of the food. The result is a visually appealing package that allows consumers to see the product clearly, making it an excellent choice for retail display.

Advantages of Vacuum Skin Packaging Machines

1. Extended Shelf Life One of the primary benefits of using vacuum skin packaging machines is the ability to significantly prolong the shelf life of perishable goods. By limiting exposure to oxygen and bacteria, foods such as meats, cheeses, and prepared meals can remain fresh for extended periods without the need for preservatives.

2. Enhanced Visual Appeal Vacuum skin packaging creates an eye-catching, tight-sealed appearance that makes products look more appealing on store shelves. The transparency of the packaging allows consumers to see the product while still being adequately protected. This feature is particularly important in the competitive food market, where presentation can influence purchasing decisions.

3. Reduced Food Waste With longer shelf lives and better preservation of quality, vacuum skin packaging helps reduce food waste. Retailers and consumers alike are benefiting from decreased spoilage rates, leading to more sustainable practices in food consumption and supply chain management.

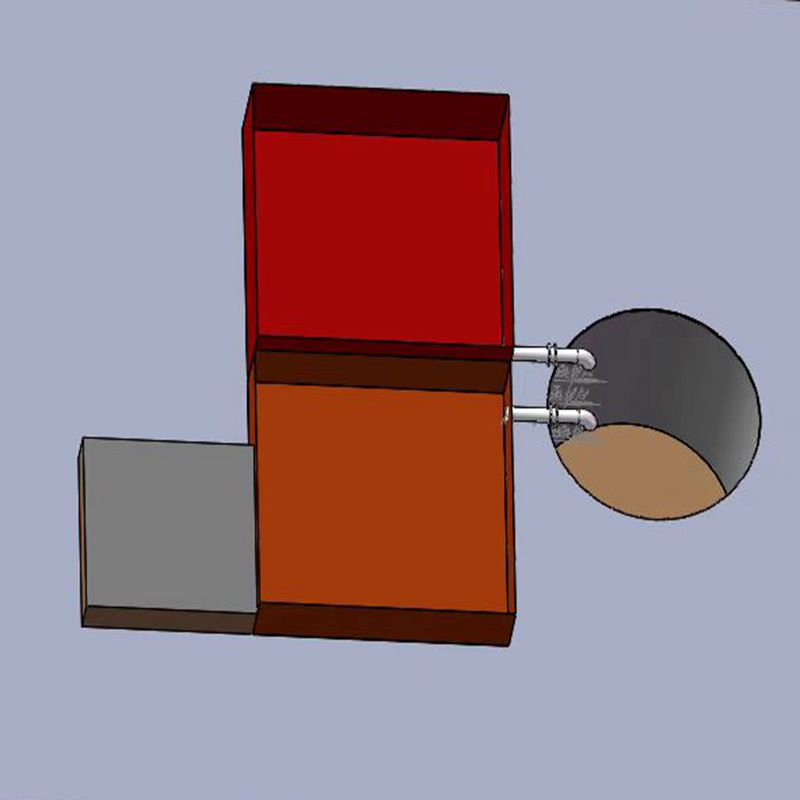

vacuum skin packaging machine

4. Protection Against Physical Damage The snug fit of vacuum skin packaging acts as a barrier against physical damage during transportation and handling. This is especially crucial for fragile items like cheeses or cooked meals, ensuring they arrive at the consumer in optimal condition.

5. Improved Flavor and Quality Retention The vacuum sealing process helps to lock in flavors and moisture, ensuring that the food maintains its authentic taste and texture. This aspect is particularly vital for gourmet and high-quality products, where maintaining flavor integrity is essential.

How Vacuum Skin Packaging Machines Work

Vacuum skin packaging machines operate through a series of specific steps. Initially, the product is placed in a tray, and the machine then covers it with a plastic film. The machine creates a vacuum around the product, sucking out all the air and creating a tight seal. Once the vacuum is achieved, the machine heats the film to bond it securely to the tray, forming a skin-like layer around the product. This process not only ensures an airtight seal but also enhances the package's overall strength and durability.

Applications Beyond Food

While vacuum skin packaging machines are predominantly used in the food industry, their applications extend to other sectors as well. For instance, they are used in the packaging of pharmaceuticals, electronics, and medical devices, where protection from moisture and air is equally crucial. This versatility makes vacuum skin packaging machines a valuable asset across various industries.

Conclusion

In conclusion, the vacuum skin packaging machine is a remarkable innovation that enhances food preservation, presentation, and quality. Its impact on extending shelf life, reducing food waste, and improving product appeal makes it an indispensable tool in modern food packaging practices. As technology continues to evolve, we can expect even more advanced solutions that cater to the growing demands of consumers and businesses alike. Embracing these technologies not only benefits industries but also contributes to a more sustainable future in food consumption and packaging.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025