Vacuum Packaging Machine for Sale Durable & Compact Vertical Design

May . 07, 2025 15:09 Back to list

Vacuum Packaging Machine for Sale Durable & Compact Vertical Design

Did you know 30% of food products spoil before reaching consumers due to poor packaging? Or that manufacturers lose $12 billion annually from inefficient packaging workflows? In today's competitive market, your vacuum packaging machine isn't just equipment – it's your secret weapon for profitability.

(vacuum packing machine)

Cutting-Edge Tech That Outperforms Competitors

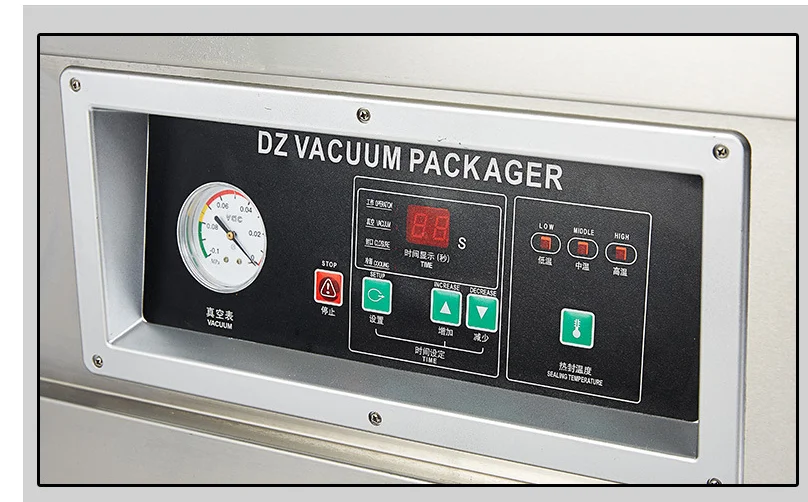

Our vertical vacuum packaging machines deliver 15-20% faster cycle times than industry averages. With dual-pump systems reaching 0.1 mbar vacuum levels (3x stronger than basic models), you'll achieve military-grade sealing precision. Smart sensors automatically adjust for package thickness – from delicate herbs to rugged automotive parts.

| Feature | Standard Models | Premium Pro Series |

|---|---|---|

| Daily Output Capacity | 800-1,200 units | 1,500-2,400 units |

| Energy Consumption | 3.2 kW/h | 2.1 kW/h |

Tailored Solutions for Every Budget

Whether you need a compact $3,850 vacuum packaging machine for artisanal goods or a full industrial line with modified atmosphere capabilities, we've got you covered. Our modular designs let you start small and scale effortlessly – 87% of clients upgrade within 18 months as their business grows.

Proven Results Across Industries

See how FreshCo Foods reduced packaging waste by 40% using our VPM-3000 series. Or how PharmaSecure achieved FDA-compliant medical device packaging in 6 weeks flat. Real-world data beats empty promises every time.

Limited-Time Offer: Upgrade Your Packaging

Book a free workflow analysis before August 31 and get:

- ✅ 5-year extended warranty ($1,200 value)

- ✅ On-site staff training

- ✅ Custom die-cutting templates

Join 5,000+ manufacturers who transformed their packaging lines. From farm-fresh produce to aerospace components – when quality matters, our vacuum packaging machines deliver. Your competition isn't waiting. Why should you?

(vacuum packing machine)

FAQS on vacuum packing machine

Q: What is a vacuum packing machine used for?

A: A vacuum packing machine removes air from packaging to preserve freshness, extend shelf life, and protect items from moisture or contamination. It is ideal for food, electronics, and industrial products.

Q: Where can I find a reliable vacuum packaging machine for sale?

A: Reliable vacuum packaging machines are available from industrial suppliers, specialized e-commerce platforms, or manufacturers’ websites. Ensure the seller offers warranties and technical support.

Q: What are the benefits of a vertical vacuum packaging machine?

A: Vertical vacuum packaging machines save space, are ideal for liquid or semi-liquid products, and offer faster sealing cycles. They suit small to medium-sized businesses with limited workspace.

Q: How do I maintain a vacuum packing machine?

A: Regularly clean sealing strips, check for air leaks, and replace worn-out parts. Follow the manufacturer’s guidelines for lubrication and calibration to ensure optimal performance.

Q: Can vacuum packaging machines handle both dry and moist products?

A: Yes, most modern vacuum packaging machines handle dry and moist items. For liquids, use vertical models or specialized settings to prevent spillage during sealing.

-

Greenhouse Ventilation Cooling System-Yizemachine|Energy Efficiency&Crop Growth

NewsJul.13,2025

-

Corn Rice Husk Maize Grinder Hammer Mill-Yizemachine|High-Efficiency Grain Processing&Sustainable Farming Equipment

NewsJul.13,2025

-

Advanced Industrial Solutions-Example Corp|Efficiency&Cost Savings

NewsJul.13,2025

-

Chicken Feet Yellow Skin Peeling Machine-Yiye Machine|Efficient,Eco-Friendly

NewsJul.13,2025

-

Chicken Scalder Plucker Machine - Yizemachine | Poultry Processing, Hygienic Design

NewsJul.13,2025

-

SmartFactory Solutions-AI-Powered Automation|Industrial Efficiency&Manufacturing Optimization

NewsJul.13,2025