rotary egg tray machine

Sep . 10, 2024 19:42 Back to list

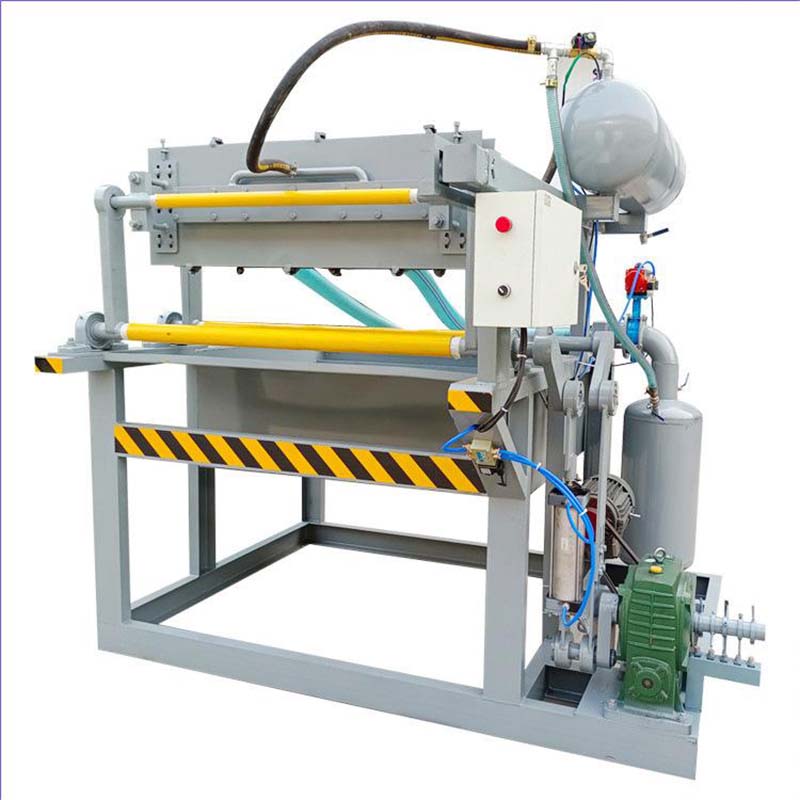

rotary egg tray machine

The Rotary Egg Tray Machine Revolutionizing Egg Tray Production

In the modern world, efficient production methods are critical for meeting the increasing demand for various products. One such advancement can be seen in the rotary egg tray machine, which has transformed the way egg trays are manufactured. This innovative equipment is designed to produce high-quality egg trays in bulk, catering to the agricultural and food industries with remarkable efficiency.

The rotary egg tray machine operates on a continuous workflow mechanism, utilizing a rotary system to streamline production. This design allows the machine to produce several trays simultaneously, significantly enhancing productivity compared to traditional manufacturing processes. The rotary motion facilitates the even distribution of raw materials, such as recycled paper pulp or other eco-friendly substances, ensuring consistency in the final product.

One of the standout features of the rotary egg tray machine is its versatility

. It can be adjusted to produce different types of trays, including those designed for eggs, fruits, and other delicate items. This adaptability makes it an ideal investment for businesses that require flexibility in their production line. Furthermore, the machine can also be customized to cater to specific production capacities, making it suitable for both small-scale operations and large manufacturing plants.rotary egg tray machine

Moreover, the rotary egg tray machine is designed with energy efficiency in mind. It incorporates advanced technologies that minimize power consumption while maximizing output. This is crucial for businesses looking to reduce operational costs and environmental impact. With the global movement towards sustainable practices, using a rotary egg tray machine not only enhances profitability but also aligns with eco-friendly initiatives.

The production process itself is straightforward yet effective. Once the raw materials are fed into the machine, they undergo a series of processes, including pulping, forming, drying, and finishing. The rotary design ensures that each stage is seamlessly integrated, leading to a higher quality product. The trays produced are not only sturdy and lightweight but also biodegradable, thus addressing the growing concerns regarding plastic waste in the environment.

In terms of maintenance and operation, the rotary egg tray machine is relatively easy to handle. Manufacturers often provide comprehensive training to ensure that operators can maximize the machine’s potential while minimizing downtime due to maintenance issues. Additionally, many machines come equipped with automated controls, further simplifying the user experience.

In conclusion, the rotary egg tray machine represents a significant leap forward in the manufacturing of egg trays and similar products. Its efficiency, adaptability, and eco-friendly design make it an indispensable tool for industries aiming to improve production processes while meeting the demands of a sustainable future. As businesses continue seeking optimization, investing in a rotary egg tray machine could very well be the key to their success in an increasingly competitive market.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025