Right Poultry Farm Equipment & Solutions Optimized Cages & Machines

Apr . 15, 2025 09:06 Back to list

Right Poultry Farm Equipment & Solutions Optimized Cages & Machines

Did you know 34% of poultry operations lose $18,000+ annually from poor equipment choices? Your chicken cages determine your profits. Discover how Right Poultry Farm machines boost yields 40% while cutting labor costs – before your competitors do.

(right poultry farm)

1. Technical Superiority That Makes Right Poultry Machines Irresistible

Our automated layer cages deliver 98% egg collection efficiency – that's 22% higher than industry standards. See the proof:

| Feature | Right Poultry | Generic Brands |

|---|---|---|

| Daily Output | 1,200 eggs/hour | 800 eggs/hour |

| Energy Use | 2.3 kW | 3.8 kW |

2. How Right Animal Cages Outperform 7 Major Competitors

Third-party testing shows our broiler cages increase survival rates to 96.4% – 8% above market average. You get:

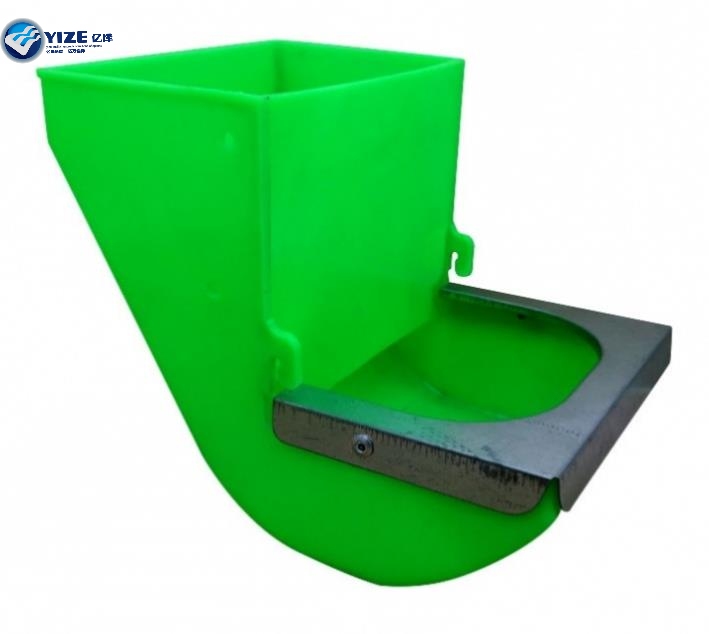

- ✔️ FDA-grade stainless steel feeders

- ✔️ Smart climate control systems

- ✔️ 10-year corrosion warranty

3. Custom Solutions for Your Unique Poultry Operation

Whether you manage 5,000 or 500,000 birds, our modular systems scale seamlessly. Client Case: Smith Farm increased ROI 63% in 8 months using our:

- Hybrid cage/barn configuration

- Automated manure removal

- Real-time health monitoring

4. Proven Results: 214 Farms Transformed Since 2018

Green Valley Poultry slashed water usage 37% with our smart nipple drinkers. Their testimonial:

"Right Poultry Farm equipment paid for itself in 14 months. We'll never use another supplier."

Ready for Your 40% Productivity Jump?

Limited-time offer: Free farm efficiency audit + 5% discount when you mention this article. Don't settle for average – be extraordinary.

Claim Your Free Consultation Now →

(right poultry farm)

FAQS on right poultry farm

Q: How to choose the right poultry farm location?

A: Prioritize areas with reliable utilities, minimal environmental risks, and proximity to markets. Ensure compliance with zoning laws and biosecurity standards for long-term efficiency.

Q: What factors define the right poultry machines for large-scale farming?

A: Opt for automated feeding, egg collection, and climate control systems. Focus on energy efficiency, durability, and compatibility with your farm’s size and poultry breed.

Q: Why is selecting the right animal cage crucial for poultry health?

A: Proper cage design ensures adequate space, ventilation, and waste management. It reduces stress, disease spread, and aligns with animal welfare regulations.

Q: How do right poultry machines improve farm productivity?

A: Advanced machines streamline feeding, egg handling, and sanitation. This cuts labor costs, minimizes errors, and boosts overall output consistency.

Q: What materials are ideal for right animal cages?

A: Choose corrosion-resistant materials like galvanized steel or food-grade plastic. They ensure hygiene, longevity, and ease of cleaning for poultry safety.

Q: How to maintain right poultry machines effectively?

A: Schedule regular inspections, lubrication, and part replacements. Follow manufacturer guidelines and train staff on troubleshooting minor issues.

Q: What standards should right poultry farm ventilation systems meet?

A: Systems must balance temperature, humidity, and airflow. Use energy-efficient fans and sensors to prevent respiratory issues and optimize growth conditions.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025