Effective Techniques for Poultry Scalding in Modern Processing Plants

Sep . 24, 2024 18:15 Back to list

Effective Techniques for Poultry Scalding in Modern Processing Plants

Understanding Poultry Scalders A Key Component in Processing

Poultry scalders play a critical role in the meat processing industry, specifically within the poultry sector. These machines are designed to facilitate the effective and humane preparation of birds for meat production. Understanding their function, types, and operational techniques can provide valuable insights into modern poultry processing.

At its core, a poultry scalder is a vessel, generally filled with hot water, where birds post-slaughter are immersed to facilitate the removal of feathers. This operation is essential to ensure that the poultry is hygienically prepared for further processing and eventual consumption. The scalding process not only aids in feather removal but also helps in loosening the skin, which can enhance the overall quality of the meat.

The optimal temperature for scalding typically ranges between 50 to 65 degrees Celsius (122 to 149 degrees Fahrenheit). It is crucial for processors to maintain these temperatures because scalding that is too hot can negatively impact meat quality, leading to loss of skin integrity and potential degradation of muscle tissue. Conversely, if the water is too cool, feathers may not come off easily, resulting in additional processing time and potential contamination.

There are two primary types of poultry scalders utilized in processing plants dry scalders and wet scalders. Dry scalders use hot air for feather loosening, while wet scalders utilize hot water. Wet scalders are more common as they often provide a more efficient and effective feather removal process. Within the realm of wet scalders, variations exist, such as open vs. closed systems. Closed systems recirculate water, maintaining temperature and chemical balance, reducing water waste and improving efficiency.

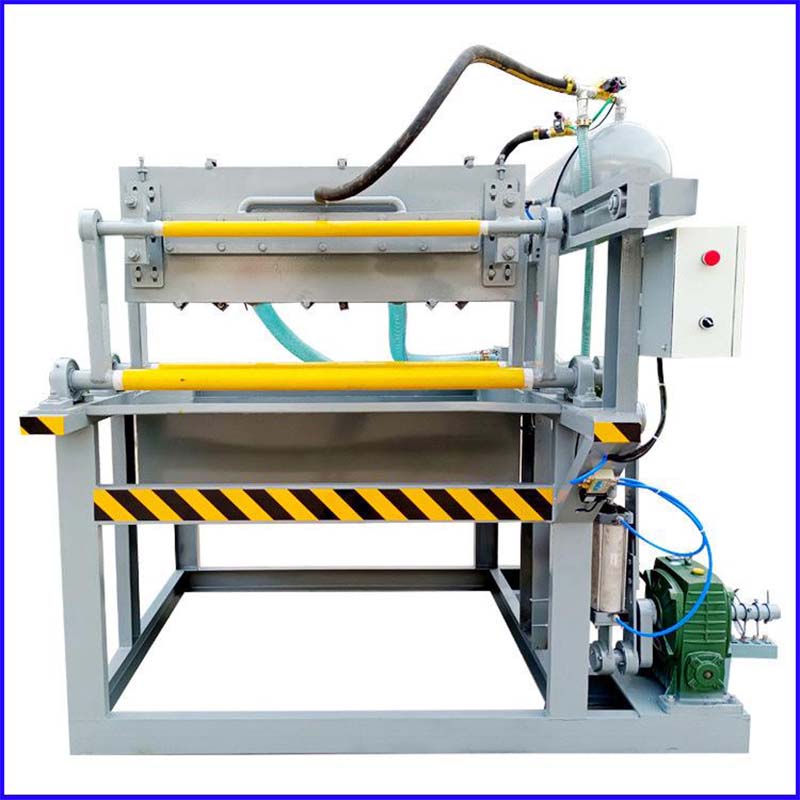

poultry scalders

The operation of poultry scalders is typically automated, involving sophisticated controls for temperature regulation and timed immersion intervals

. Modern machines may also include features such as adjustable speed and variable temperature control, allowing operators to customize the process based on the type and size of poultry being processed.The significance of poultry scalders extends beyond mere feather removal. A well-designed scalder ensures the humane treatment of birds by minimizing stress and pain during processing. Compliance with animal welfare standards is paramount in today’s meat production industry, and efficient scalding procedures contribute to meeting these ethical guidelines.

In addition to welfare considerations, scalders have a substantial impact on the overall efficiency of processing operations. By streamlining the feather removal process, processors can improve throughput and ensure faster turnaround times, ultimately contributing to cost-effectiveness. Moreover, improved meat quality resulting from optimal scalding conditions can enhance market appeal, benefiting producers economically.

In conclusion, poultry scalders are an indispensable component of poultry processing, vital for ensuring quality, efficiency, and humane treatment of birds. As technology advances, the design and functionality of these machines continue to evolve, promising even greater efficiencies and sustainability within the industry. Understanding the importance of scalders not only aids in appreciating the intricacies of poultry processing but also highlights the ongoing efforts to align production practices with ethical standards. This balance of efficiency and responsibility will be essential in meeting the growing global demand for poultry products in a conscientious manner.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025