poultry farm layer cage

Jan . 19, 2025 01:59 Back to list

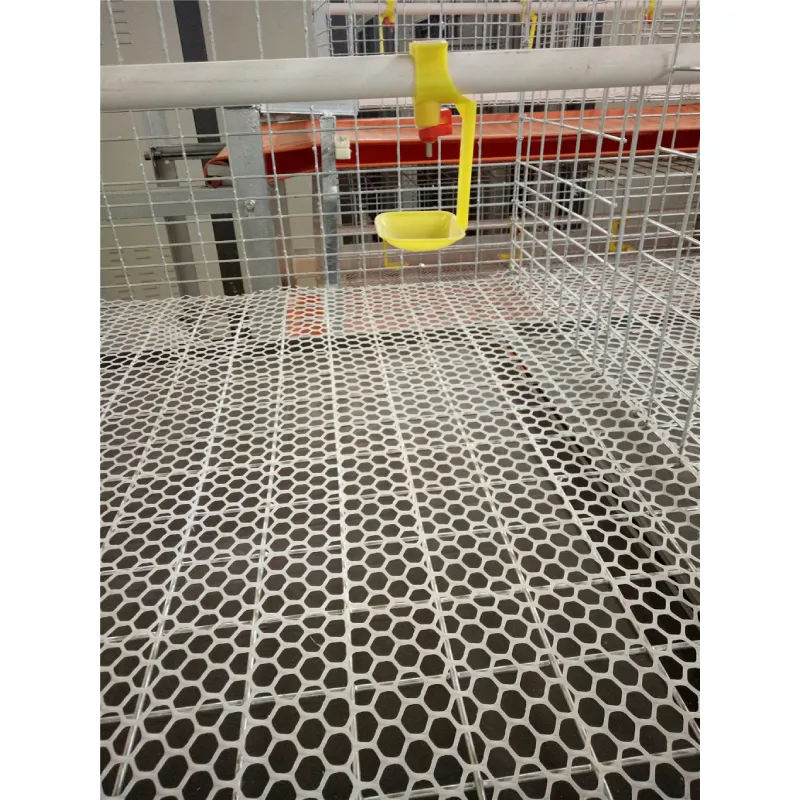

poultry farm layer cage

In the heart of modern poultry farming, layer cages play an instrumental role in enhancing both productivity and animal welfare. These specialized enclosures, meticulously engineered, provide optimal conditions for raising hens primarily for egg production. Drawing from real-life insights and industry expertise, let's delve into what makes a high-quality poultry farm layer cage a cornerstone in the world of egg farming.

Trustworthiness in the context of layer cages stems from their proven track record in farm operations across the globe. Farmers value these cages not only for their practicality and effectiveness in producing eggs but also for the prolonged lifespan and durability they offer, making them a cost-effective investment. Reliable manufacturers provide warranties and customer support, ensuring farmers have access to help and service as needed, thus bolstering the trust factor further. In essence, a poultry farm layer cage transcends its physical structure. It symbolizes an integration of humane poultry farming practices with the industrial capabilities to meet global food demands. As the need for sustainably sourced eggs rises, the demand for proficient layer cages only grows stronger, propelling continuous advancements and targeted solutions tailored to specific farm environments. When choosing a layer cage, farmers should evaluate their specific needs and priorities. Whether it’s the scale of operation, climate conditions, or local regulations, selecting the right cage means balancing these factors with innovative solutions. Future trends are leaning towards even more automation within these structures, including features like automated feeding, temperature regulation, and data-driven insights into the health and productivity of the hens. This journey of understanding and optimizing layer cage systems underscores the diverse synergy between technology, animal welfare, and human ingenuity. By leveraging the collective experience and expertise within the poultry farming industry, these systems continually empower farmers to meet the challenges of today’s rigorous agricultural landscape with confidence and foresight. As these technological evolutions unfold, poultry farm layer cages remain a pivotal aspect of efficient and ethical egg production.

Trustworthiness in the context of layer cages stems from their proven track record in farm operations across the globe. Farmers value these cages not only for their practicality and effectiveness in producing eggs but also for the prolonged lifespan and durability they offer, making them a cost-effective investment. Reliable manufacturers provide warranties and customer support, ensuring farmers have access to help and service as needed, thus bolstering the trust factor further. In essence, a poultry farm layer cage transcends its physical structure. It symbolizes an integration of humane poultry farming practices with the industrial capabilities to meet global food demands. As the need for sustainably sourced eggs rises, the demand for proficient layer cages only grows stronger, propelling continuous advancements and targeted solutions tailored to specific farm environments. When choosing a layer cage, farmers should evaluate their specific needs and priorities. Whether it’s the scale of operation, climate conditions, or local regulations, selecting the right cage means balancing these factors with innovative solutions. Future trends are leaning towards even more automation within these structures, including features like automated feeding, temperature regulation, and data-driven insights into the health and productivity of the hens. This journey of understanding and optimizing layer cage systems underscores the diverse synergy between technology, animal welfare, and human ingenuity. By leveraging the collective experience and expertise within the poultry farming industry, these systems continually empower farmers to meet the challenges of today’s rigorous agricultural landscape with confidence and foresight. As these technological evolutions unfold, poultry farm layer cages remain a pivotal aspect of efficient and ethical egg production.

Next:

Latest news

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025