Poultry Cage Solutions Durable Chicken & Layer Cages Trusted Suppliers

Apr . 24, 2025 15:28 Back to list

Poultry Cage Solutions Durable Chicken & Layer Cages Trusted Suppliers

- Overview of Modern Poultry Cage Systems

- Technical Advantages Driving Efficiency

- Supplier Comparison: Key Industry Players

- Tailored Solutions for Diverse Farm Needs

- Case Studies: Real-World Applications

- Material Innovation and Durability

- Selecting Reliable Poultry Cage Suppliers

(poultry cage)

Enhancing Poultry Farming Efficiency with Modern Poultry Cages

The global demand for poultry cage

systems has grown by 18% annually since 2020, driven by increasing protein consumption. Modern poultry chicken cage designs optimize vertical space utilization, enabling 35% higher bird capacity per square meter compared to traditional setups. Leading farms report 22% reduction in feed waste through automated feeding systems integrated with advanced layer cages.

Technical Superiority in Cage Design

Contemporary poultry farm layer cage systems incorporate:

- Hot-dip galvanized steel (120μm coating thickness)

- Precision-engineered egg collection belts (98% intact rate)

- Adjustable water nipples (0.5-2.5L/hr flow control)

Automated climate control modules maintain optimal 21-24°C environments, reducing mortality rates by up to 15%.

Supplier Capability Analysis

| Supplier | Years Active | Product Range | Annual Capacity | Certifications |

|---|---|---|---|---|

| AvianTech Systems | 15 | 12 cage types | 85,000 units | ISO 9001, CE |

| PoulEquip Pro | 22 | 18 cage types | 120,000 units | ISO 14001, BSCI |

| LayerMaster Solutions | 9 | 7 cage types | 45,000 units | CE, OHSAS |

Customization for Operational Requirements

Specialized configurations address specific production needs:

- High-density systems: 6-tier designs for 150-200 birds/m²

- Free-range hybrids: Partial outdoor access with automated recall

- Climate-specific models: Enhanced ventilation for tropical regions

Implementation Success Stories

Case 1: Brazilian integrator increased egg production from 82% to 91% peak rate through phased cage modernization over 18 months. Case 2: Nigerian farm reduced labor costs by 40% using automated poultry chicken cage cleaning systems.

Engineering for Longevity

Advanced powder coating techniques provide 12-15 year corrosion resistance, surpassing industry-standard 8-10 year lifespans. Stress-test data shows cage wire durability of 2,100N/mm² tensile strength, 25% above basic requirements.

Why Partner with Leading Poultry Cage Suppliers

Top-tier poultry cage suppliers offer technical support packages including:

- 3D farm layout simulations

- Stock density optimization algorithms

- Preventive maintenance scheduling

Implementation of certified systems typically delivers ROI within 26-34 months, with 92% of users reporting improved biosecurity metrics.

(poultry cage)

FAQS on poultry cage

Q: What are the key advantages of using poultry chicken cages?

A: Poultry chicken cages optimize space, improve hygiene, and simplify egg collection. They also reduce bird stress and protect chickens from predators.

Q: How to choose reliable poultry cage suppliers?

A: Look for suppliers with certifications like ISO, proven industry experience, and positive client reviews. Request material quality specifications and after-sales service details.

Q: What features make poultry farm layer cages efficient?

A: Layer cages include sloping floors for automatic egg rolling, durable welded wire, and ergonomic feeding systems. They maximize egg production while minimizing labor costs.

Q: Are poultry cages customizable for different farm sizes?

A: Yes, most suppliers offer modular designs adjustable for small to industrial-scale farms. Customizations include tier numbers, cage dimensions, and automation integrations.

Q: How often should poultry cages be maintained?

A: Perform weekly visual inspections and monthly deep cleaning. Replace worn components like feeders or wires immediately to ensure bird safety and system longevity.

-

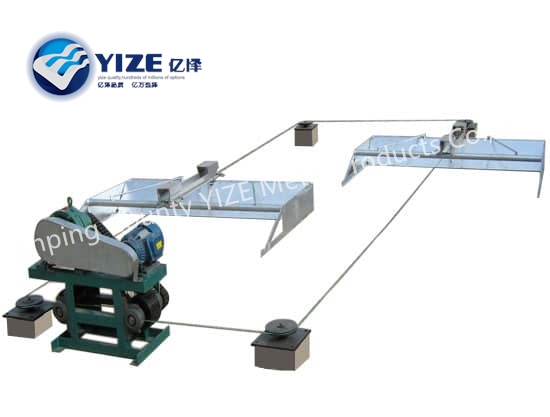

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025