paper pulp egg tray making machine

Dec . 10, 2024 05:47 Back to list

paper pulp egg tray making machine

The Paper Pulp Egg Tray Making Machine A Sustainable Solution for Egg Packaging

In the world of packaging solutions, sustainability has emerged as a paramount concern. The rise in environmental awareness has led to a surge in demand for eco-friendly alternatives, particularly in the food industry. One noteworthy innovation in this domain is the paper pulp egg tray making machine, a device that offers an environmentally friendly solution for egg packaging while also making efficient use of waste materials.

What is a Paper Pulp Egg Tray Making Machine?

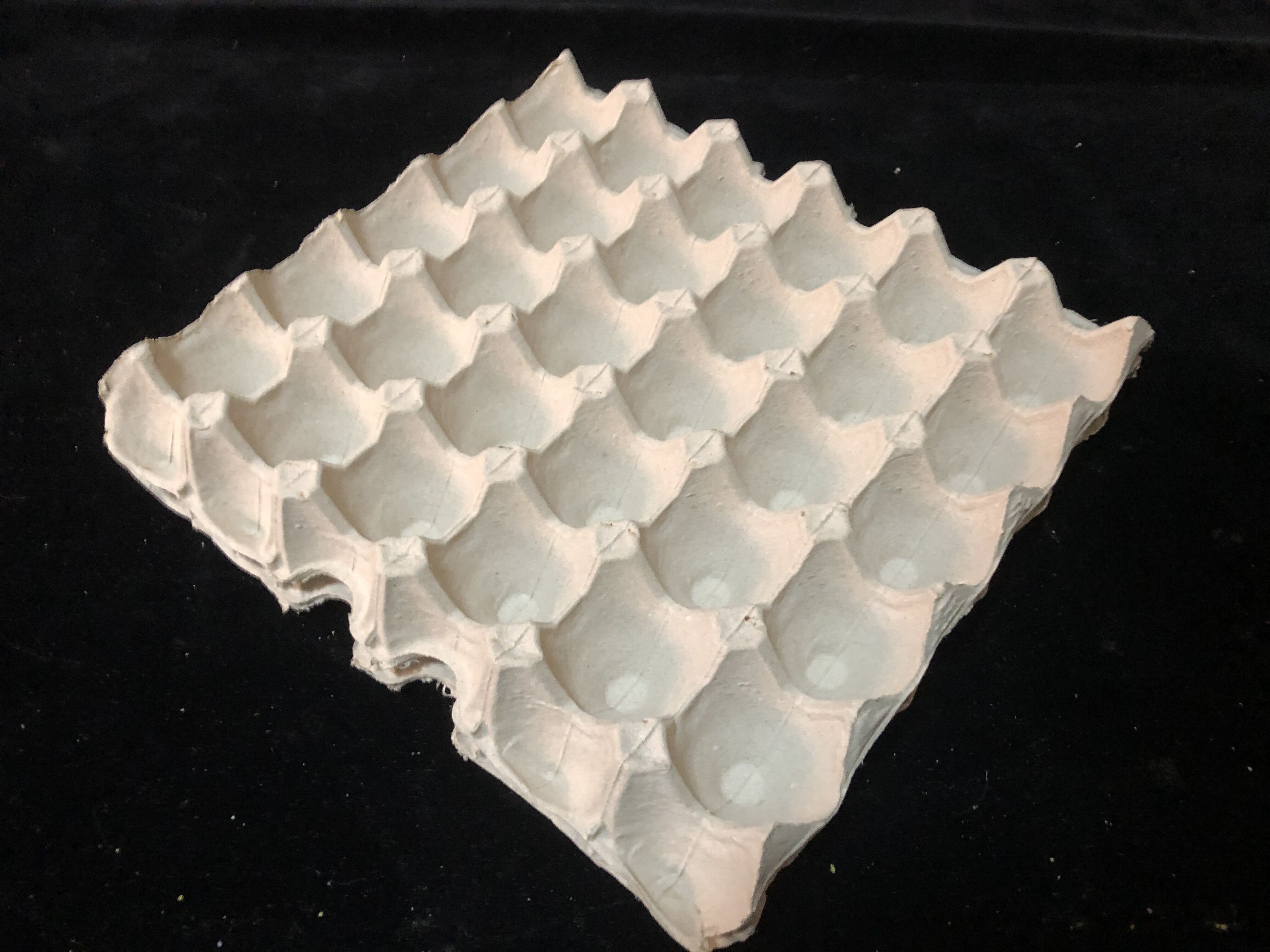

A paper pulp egg tray making machine is designed to convert waste paper products into molded pulp trays, specifically engineered to accommodate and protect eggs during transport. This machinery utilizes a combination of recycling techniques and molding processes to create egg trays that are not only biodegradable but also sturdy enough to prevent breakage.

The process begins with the collection of waste paper, which can include newspapers, cardboard, and other paper products. These materials are then shredded and mixed with water to create a pulp. Once the pulp is prepared, it is poured into molds that define the shape of the egg trays. After molding, the trays are dried, resulting in a product that is lightweight, durable, and environmentally friendly.

Environmental Benefits

One of the most significant advantages of using paper pulp egg trays is their environmental impact. Traditional egg packaging often involves plastic or polystyrene, which can take hundreds of years to decompose in landfills. In contrast, molded pulp trays are made from biodegradable materials, making them a sustainable choice. Furthermore, by using recycled paper, the process reduces the need for new raw materials, thus conserving trees and reducing energy consumption associated with paper production.

The production of paper pulp trays also consumes less energy than manufacturing plastic equivalents. This energy efficiency, combined with the reduction of plastic waste, contributes to a smaller carbon footprint for businesses involved in egg production and sales.

Economic Advantages

Investing in a paper pulp egg tray making machine can offer significant economic benefits. For poultry farmers and egg producers, this machinery represents an opportunity for cost savings. By producing their own trays, they can reduce or eliminate the need to purchase packaging materials from external suppliers. This not only lowers operational costs but also provides greater control over the quality and sustainability of the packaging they use.

paper pulp egg tray making machine

Additionally, as consumers become more environmentally conscious, businesses that adopt sustainable practices are likely to gain a competitive advantage. Offering eggs in eco-friendly packaging can enhance a brand's image and appeal to a growing demographic of eco-conscious consumers, potentially leading to increased sales.

Training and Maintenance

While the initial investment in a paper pulp egg tray making machine can be significant, the long-term benefits often outweigh the costs. However, it is essential for businesses to provide adequate training for their employees on the operation and maintenance of the machinery. Proper handling and regular maintenance ensure that the machine operates efficiently and produces high-quality trays.

Operators should be trained in the processes of pulping, molding, and drying, as each step plays a crucial role in the final product's quality. Over time, with the right practices in place, the machine can produce uniform and reliable trays that meet industry standards.

Future of Egg Packaging

As industries shift toward sustainable practices, the role of paper pulp egg tray making machines is likely to grow. Innovations in this field could lead to enhancements in production efficiency, tray design, and even new applications beyond egg packaging, such as for fruits or other fragile items.

Furthermore, as technology advances, we may witness the emergence of even more efficient machines that can utilize a broader range of raw materials, including agricultural waste. This would not only further reduce environmental impact but also provide additional income streams for farmers and manufacturers.

Conclusion

The paper pulp egg tray making machine reflects a significant step toward sustainable packaging solutions in the agricultural sector. By transforming waste paper into biodegradable products, it not only addresses environmental concerns but also offers economic advantages for producers. As the demand for sustainable practices continues to rise, investing in such technology will likely prove beneficial for businesses looking to thrive in a more environmentally conscious marketplace.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025