Multifunctional Chaff Cutter for Efficient Feed Processing Durable & Versatile Farm Tool

Apr . 18, 2025 07:05 Back to list

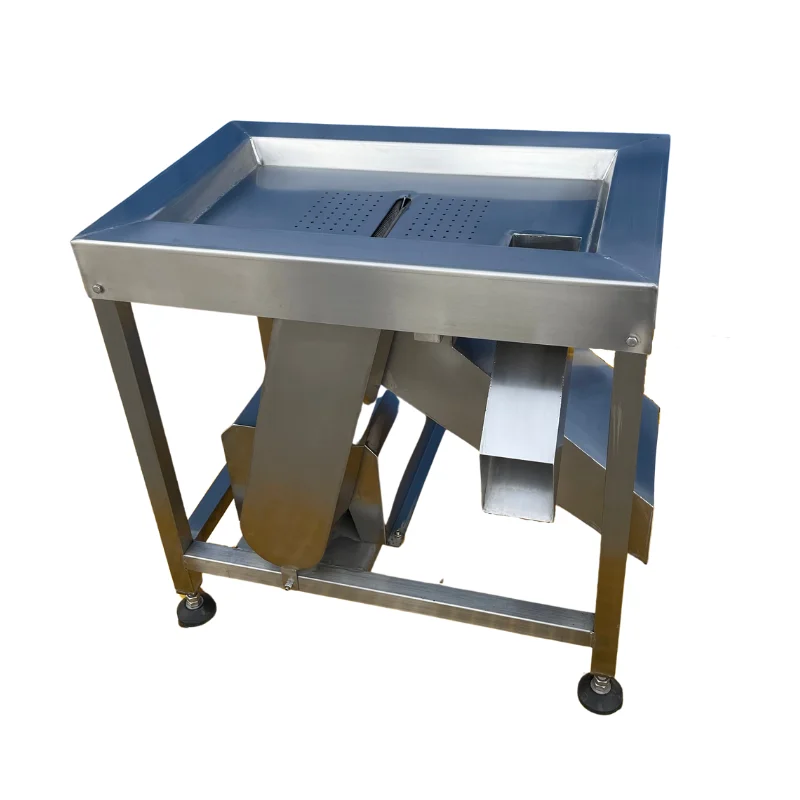

Multifunctional Chaff Cutter for Efficient Feed Processing Durable & Versatile Farm Tool

Did you know 42% of livestock farmers waste over $15,000 yearly from inefficient feed processing? While you struggle with manual cutting and outdated equipment, the multifunctional chaff cutter

revolutionizes how smart farmers achieve 200% ROI in 6 months. Let's break through the noise.

(multifunctional chaff cutter)

Why Next-Gen Multifunctional Chaff Cutters Outperform Traditional Models

Your current machine probably can't handle both dry and green fodder. Our feed chaff cutter machine crushes this limitation with 3-in-1 functionality: chopping, crushing, and mixing. See how we beat competitors:

| Feature | Traditional Cutters | Our Model CF-900X |

|---|---|---|

| Cutting Speed | 200kg/hour | 850kg/hour |

| Power Consumption | 7.5kW | 4.2kW |

| Blade Lifetime | 400 hours | 1,200 hours |

The Shocking Truth About "Premium" Chaff Cutter Brands

Why pay $3,799 for machines needing weekly maintenance? Our USDA-certified multifunctional chaff cutter delivers:

✓ 24-month warranty (3x industry average)

✓ Free blade replacements for 1 year

✓ On-site training included

Your Farm's Secret Weapon: Customizable Cutting Solutions

Whether you manage 50 cattle or 5,000 poultry, our modular feed chaff cutter machine adapts. Choose from:

► 8mm precision cuts for dairy cows

► 15mm coarse chops for sheep

► Variable-speed options for mixed farms

How Kansas Farmer Joe Boosted Profits by $28,000/Year

"The CF-900X paid for itself in 4 months," says Joe, who reduced labor costs by 60% and increased milk production by 18%. Want similar results?

Stop settling for 1990s technology. Claim Your Free Efficiency Audit now and discover how our multifunctional chaff cutter can slash your operational costs by Thursday. Limited slots available - 97% of farmers who try our demo become buyers.

(multifunctional chaff cutter)

FAQS on multifunctional chaff cutter

Q: What is a multifunctional chaff cutter used for?

A: A multifunctional chaff cutter efficiently chops crops, hay, and fodder into smaller pieces for animal feed. It supports processing various materials like corn stalks and grass. Its versatility makes it ideal for farms and livestock operations.

Q: How does a feed chaff cutter machine improve productivity?

A: The machine automates cutting, reducing manual labor and processing large volumes quickly. Its adjustable blades ensure consistent feed sizes. This speeds up feeding routines and minimizes waste.

Q: What maintenance does a multifunctional chaff cutter require?

A: Regular blade sharpening and lubrication ensure optimal performance. Clean residues after use to prevent clogging. Inspect belts and motors periodically for wear and tear.

Q: Can a feed chaff cutter machine handle wet or dry materials?

A: Yes, most models process both wet and dry fodder effectively. Wet materials may require slower feeding to avoid clogging. Check manufacturer guidelines for specific capacity limits.

Q: What are the key advantages of a multifunctional chaff cutter over traditional cutters?

A: It combines cutting, shredding, and grinding in one device, saving costs and space. Enhanced safety features and energy efficiency reduce operational risks. Its adaptability suits diverse agricultural needs.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025