large poultry cage

Feb . 17, 2025 17:43 Back to list

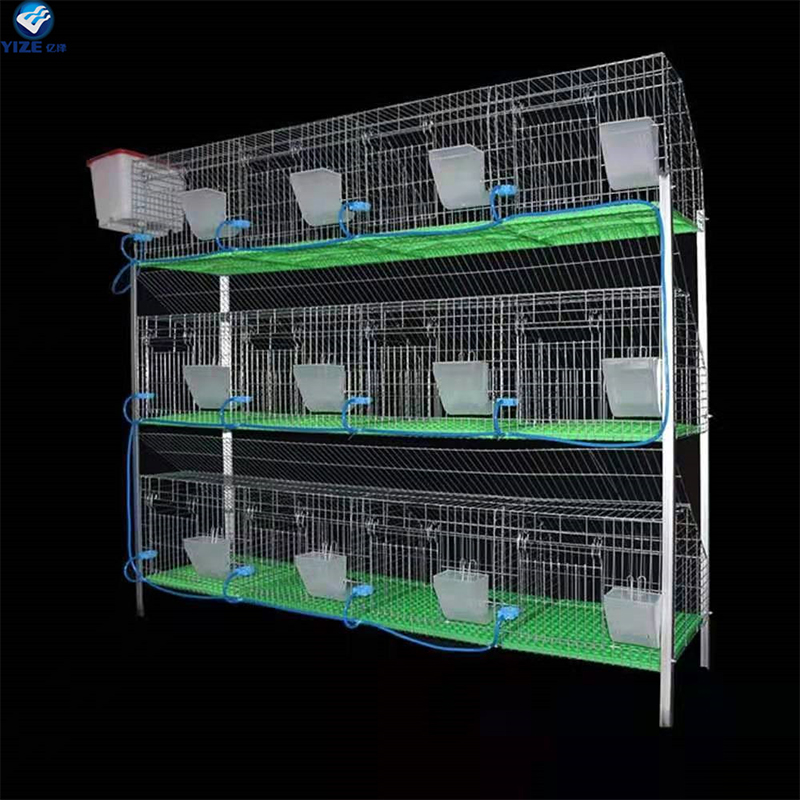

large poultry cage

Large poultry cages play a pivotal role in the modern poultry farming industry, offering an efficient method for housing and raising birds. When selecting the right cage, several key factors must be considered to ensure both the welfare of the birds and the productivity of the farm. This article delves into the nuanced details of choosing the best large poultry cage, highlighting expert insights and industry practices that are pivotal for success.

On the technical front, some advanced poultry cages incorporate automated systems for feeding, watering, and egg collection. These systems enhance efficiency by reducing manual labor and minimizing human error. While upfront costs may be higher, the returns in terms of labor savings and consistent production can be significant. Furthermore, biosecurity is an ongoing concern in poultry farming. Selecting cages with features that minimize the risk of disease transmission is imperative. Easy-to-clean materials, in combination with strategic cage location and layout, act as a frontline defense against potential outbreaks. The focus should be on creating a controlled environment that is both secure and conducive to poultry health. Finally, considering the economic aspect, the investment in high-quality large poultry cages should yield a significant return. Efficient designs lower operational costs, while innovations like automatic feeding systems and advanced ventilation contribute to increased production. As an authoritative voice in poultry farming, experts emphasize the importance of viewing these cages as pivotal components of a long-term strategy for growth and sustainability. In summary, choosing the right large poultry cage involves a comprehensive understanding of material quality, ventilation, space allocation, ease of maintenance, technological integration, and biosecurity measures. By balancing these aspects, poultry farmers can create optimal conditions for their flocks, ensuring not only welfare and productivity but also establishing a robust foundation for financial success and industry leadership.

On the technical front, some advanced poultry cages incorporate automated systems for feeding, watering, and egg collection. These systems enhance efficiency by reducing manual labor and minimizing human error. While upfront costs may be higher, the returns in terms of labor savings and consistent production can be significant. Furthermore, biosecurity is an ongoing concern in poultry farming. Selecting cages with features that minimize the risk of disease transmission is imperative. Easy-to-clean materials, in combination with strategic cage location and layout, act as a frontline defense against potential outbreaks. The focus should be on creating a controlled environment that is both secure and conducive to poultry health. Finally, considering the economic aspect, the investment in high-quality large poultry cages should yield a significant return. Efficient designs lower operational costs, while innovations like automatic feeding systems and advanced ventilation contribute to increased production. As an authoritative voice in poultry farming, experts emphasize the importance of viewing these cages as pivotal components of a long-term strategy for growth and sustainability. In summary, choosing the right large poultry cage involves a comprehensive understanding of material quality, ventilation, space allocation, ease of maintenance, technological integration, and biosecurity measures. By balancing these aspects, poultry farmers can create optimal conditions for their flocks, ensuring not only welfare and productivity but also establishing a robust foundation for financial success and industry leadership.

Next:

Latest news

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025