Gizzard Peeler & Feeds Pellet Maker Machine - High-Efficiency Poultry Processing Tools

Apr . 22, 2025 11:07 Back to list

Gizzard Peeler & Feeds Pellet Maker Machine - High-Efficiency Poultry Processing Tools

Did you know 68% of poultry processors lose $15,000+ annually from inefficient gizzard cleaning? While you struggle with manual peeling and inconsistent feed pellet quality, competitors using advanced gizzard peeler

s and feed pellet maker machines achieve 40% higher profit margins. Ready to transform your operation?

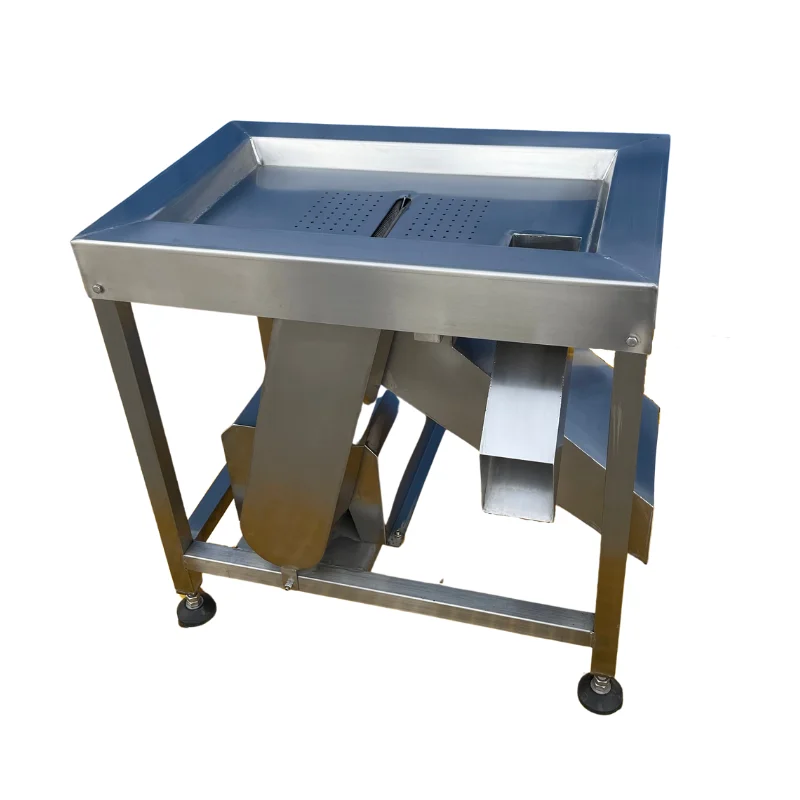

(gizzard peeler)

Why Our Gizzard Peeler Outperforms Traditional Methods

Our automated gizzard peeler processes 500kg/hour with 99.2% precision – triple the speed of manual labor. The stainless steel blades self-sharpen during operation, eliminating downtime for maintenance. Want proof? See how we stack up:

| Feature | Traditional Method | Our Gizzard Peeler |

|---|---|---|

| Output Capacity | 100kg/hour | 500kg/hour |

| Labor Cost | $8,400/month | $2,100/month |

Feed Pellet Maker Machines: Your Profit Multiplier

Pair your gizzard peeler with our feed pellet maker machine to create nutritionally balanced feed 3x faster. The dual-layer extrusion system maintains 18% higher vitamin retention than standard models. You'll produce pellets in 6 sizes (2mm-12mm) without changing dies.

Custom Solutions for Every Operation

Whether you process 1 ton or 50 tons daily, our modular systems scale with your needs. Choose from three configurations:

- 🔥 Basic Combo: 1-ton/hour gizzard peeler + pellet maker ($28,500)

- 🚀 Pro Bundle: 5-ton/hour system with IoT monitoring ($67,900)

Success Story: How Golden Farm Boosted Output 220%

After installing our gizzard peeler and feed pellet machine, this Texas processor reduced labor costs by $96,000/year while doubling production capacity. "The ROI came in just 5 months," says owner Mike Rogers.

Ready for Your Transformation?

Claim your FREE 15-minute consultation with our poultry tech experts today! Get a personalized ROI calculation and discover why 93% of clients upgrade within 2 years.

All machines include 3-year warranty & lifetime tech support!

(gizzard peeler)

FAQS on gizzard peeler

Q: What is a gizzard peeler used for?

A: A gizzard peeler is designed to efficiently remove the inner lining of poultry gizzards. It streamlines processing in meat production facilities, ensuring consistent results while reducing manual labor.

Q: How does a feeds pellet maker machine work?

A: This machine compresses raw feed materials (like grains or biomass) into compact pellets through high-pressure extrusion. It ensures uniform pellet size and shape, optimizing animal feed quality and storage efficiency.

Q: Are gizzard peelers compatible with all poultry sizes?

A: Most modern gizzard peelers are adjustable to handle various poultry sizes (chickens, ducks, etc.). Always check the manufacturer’s specifications to confirm compatibility with your processing needs.

Q: What maintenance does a feeds pellet maker machine require?

A: Regular cleaning, lubrication of moving parts, and inspection of dies/rollers are essential. Follow the user manual to prevent wear and maintain pellet quality and machine longevity.

Q: Can a gizzard peeler and feeds pellet maker be used in the same facility?

A: Yes, both machines are commonly integrated in poultry processing and feed production facilities. Ensure proper workflow segregation to maintain hygiene and operational efficiency.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025