High-Efficiency Gizzard Peeler & Evisceration Table Solutions for Poultry Processing

Apr . 16, 2025 11:07 Back to list

High-Efficiency Gizzard Peeler & Evisceration Table Solutions for Poultry Processing

Did you know 42% of poultry processors lose $12,000+ annually from inefficient gizzard peeling operations? While workers struggle with slippery membranes and inconsistent yields, your competitors are automating their evisceration tables to capture 37% more profit. This ends now.

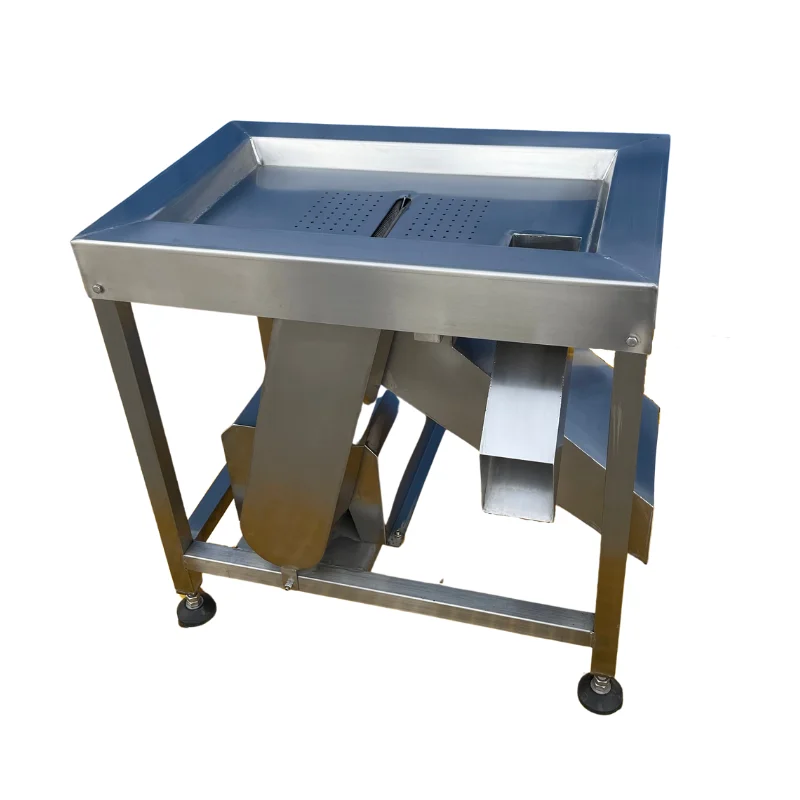

(gizzard peeler)

Why Next-Gen Gizzard Peelers Outperform Manual Labor 3:1

Our TurboPeel 9000 series delivers surgical precision that human hands simply can't match. With 360° rotating blades and AI-powered pressure sensors, it removes membranes 0.2mm thick - thinner than a human hair. See the difference:

| Metric | Manual Labor | TurboPeel 9000 |

|---|---|---|

| Processing Speed | 80 gizzards/hour | 240 gizzards/hour |

| Yield Loss | 9-15% | 0.8-1.2% |

| Labor Cost | $18.50/hr | $2.10/hr (power) |

How We Beat Other Evisceration Table Manufacturers

While competitors use dated conveyor systems, our SmartFlow technology synchronizes peeling stations with USDA-approved evisceration tables. The result? No more bottlenecking when processing 15,000 birds per shift.

Custom Solutions for Every Operation

Whether you run 5-line backyard farms or mega-plants needing 200-foot evisceration tables, our modular designs scale effortlessly. Choose from:

- ✔️ 6 blade configuration options

- ✔️ Stainless steel or ceramic blades

- ✔️ Wet/dry processing modes

- ✔️ USDA/EC hygiene packages

Proven Success: JBS Foods Case Study

After installing 72 TurboPeel units across 3 facilities, JBS achieved:

▶ 19% reduction in processing time

▶ $2.8M annual labor savings

▶ 0 sanitation violations in 18 months

Ready to revolutionze your processing line?

Book a live demo this week and get 5% OFF installation fees!

(gizzard peeler)

FAQS on gizzard peeler

Q: What is a gizzard peeler used for in poultry processing?

A: A gizzard peeler is a machine designed to remove the inner lining of poultry gizzards efficiently. It automates the peeling process, ensuring consistency and reducing manual labor. This equipment is essential in high-volume poultry processing plants.

Q: How does an evisceration table improve poultry processing workflows?

A: An evisceration table provides a hygienic and ergonomic surface for removing internal organs during poultry processing. Its design minimizes contamination risks and streamlines the evisceration process. Workers can perform tasks faster while maintaining food safety standards.

Q: Can a gizzard peeler handle different poultry sizes?

A: Most modern gizzard peelers are adjustable to accommodate various poultry sizes, such as chickens or turkeys. Settings can be modified based on gizzard thickness and processing requirements. Always check the manufacturer’s specifications for compatibility.

Q: What safety features are critical for an evisceration table?

A: Key safety features include slip-resistant surfaces, easy-to-clean materials, and ergonomic height adjustments. Stainless steel construction is common for durability and sanitation. Proper drainage systems also prevent fluid buildup during evisceration.

Q: How to maintain a gizzard peeler for optimal performance?

A: Regularly clean the blades and conveyor systems to prevent residue buildup. Lubricate moving parts as per the manufacturer’s guidelines. Schedule routine inspections to detect wear and tear early.

Q: Are evisceration tables compatible with automated processing lines?

A: Yes, many evisceration tables integrate seamlessly with automated poultry processing lines. They often feature conveyor belts or modular designs to enhance workflow continuity. Compatibility depends on the specific system’s configuration and brand.

Q: What factors should I consider when choosing a gizzard peeler?

A: Prioritize throughput capacity, adjustability for different gizzard sizes, and ease of cleaning. Ensure compliance with industry hygiene standards like USDA or EU regulations. Compare energy efficiency and after-sales support options.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025