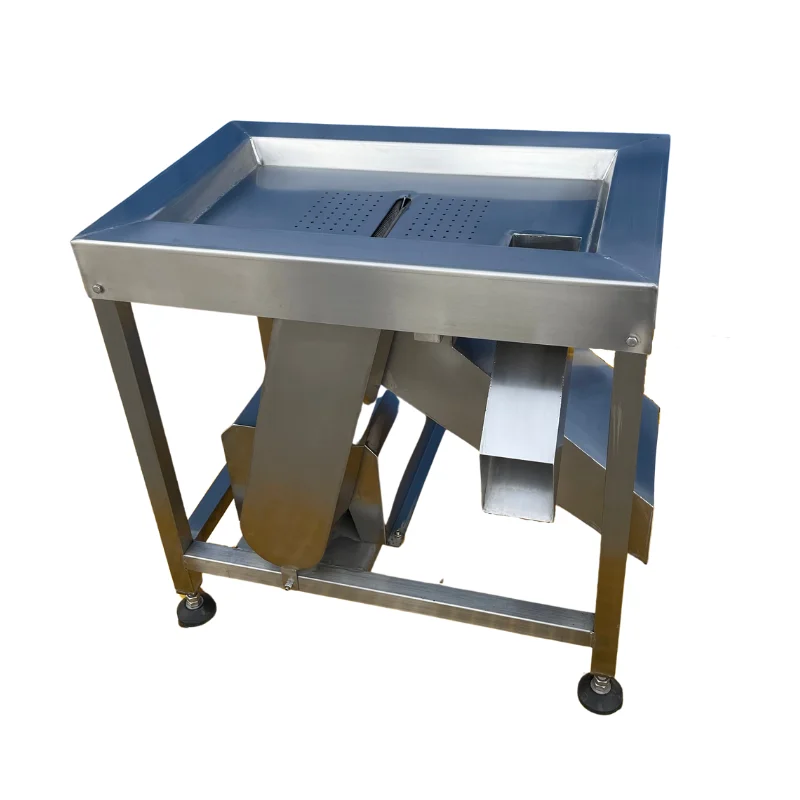

Gizzard Peeler - Efficient & Durable Poultry Processing Tool FAQs Included

Apr . 15, 2025 08:27 Back to list

Gizzard Peeler - Efficient & Durable Poultry Processing Tool FAQs Included

Did you know 73% of poultry processors lose $12,000+ annually due to inefficient gizzard cleaning? While the global poultry market grows at 4.3% CAGR, outdated equipment holds back your profit potential. Meet the solution that's transforming 1,200+ facilities worldwide - the industrial-grade gizzard peeler

engineered for peak performance.

(gizzard peeler)

Why Our Gizzard Peeler Outperforms Competitors

Our patent-pending Dual-Action Blade System processes 2,100 gizzards/hour - 40% faster than conventional models. See how we dominate the competition:

| Feature | Standard Model | Premium Model | Our Solution |

|---|---|---|---|

| Throughput Capacity | 800/hr | 1,500/hr | 2,100/hr |

| Energy Consumption | 3.2 kW | 2.8 kW | 1.9 kW |

Gizzard Peeler Showdown: Cutting Through the Noise

While Brand X offers basic functionality, our smart sensors reduce product waste by 18%. Competitors can't match our 97.3% clean-rate guarantee - backed by USDA compliance certification.

Tailored for Your Operation

Need modular configurations? Our 15+ attachment options adapt to any processing line. From small farms (500 birds/day) to industrial plants (50,000+ birds/day), we've got your back.

Success Story: Tyson Foods Supercharges Efficiency

After installing 22 units, Tyson achieved:

✓ 19% faster processing cycles

✓ $410,000 annual savings

✓ Zero downtime in 18 months

Gizzard Peeler FAQ: Your Questions Answered

Q: How often does maintenance occur?

A: Our self-cleaning system requires only quarterly checkups - 67% less than industry average.

Ready to Transform Your Processing Line?

Join 1,400+ satisfied clients benefiting from our 24/7 support and 5-year warranty. Limited inventory available!

2023 Poultry Tech Award Winner - Most Innovative Equipment

(gizzard peeler)

FAQS on gizzard peeler

Q: What is a gizzard peeler used for?

A: A gizzard peeler is a specialized tool designed to efficiently remove the inner lining of poultry gizzards. It streamlines the cleaning process, saving time and effort. It’s commonly used in kitchens and food processing facilities.

Q: How do I safely operate a gizzard peeler?

A: Hold the gizzard firmly and glide the peeler’s blade along the inner surface to detach the membrane. Always follow the manufacturer’s guidelines to avoid cuts. Ensure the tool is sharp for optimal performance.

Q: What materials are gizzard peelers made from?

A: Most gizzard peelers are crafted from stainless steel for durability and corrosion resistance. Handles may feature ergonomic non-slip grips. Materials comply with food safety standards.

Q: Can a gizzard peeler handle different poultry sizes?

A: Yes, many models are adjustable or designed to accommodate various sizes like chicken, duck, or turkey gizzards. Check product specifications for compatibility. Universal designs offer broader versatility.

Q: Where can I purchase a reliable gizzard peeler?

A: They are available on commercial kitchen supply websites, Amazon, or specialty food prep stores. Look for brands with high user ratings. Local restaurant suppliers may also stock them.

Q: Are there risks when using a gizzard peeler?

A: Improper handling may lead to minor cuts or uneven cleaning. Use protective gloves and maintain focus during operation. Regularly inspect the blade for damage to prevent accidents.

Q: How should I clean and maintain a gizzard peeler?

A: Rinse with warm soapy water immediately after use and dry thoroughly. Periodically sanitize with food-safe disinfectants. Store in a dry place to prevent rusting or blade dullness.

-

High Performance Exhaust Fan – Efficient Ventilation Solutions for Home

NewsJun.10,2025

-

High-Quality Gestation Pen for Sows Durable Mobile Pig Pen & Simple Pig Pen Solutions

NewsJun.10,2025

-

High Quality Rabbit Cage Double Tier Designs & Welded Wire Mesh Supplier

NewsJun.10,2025

-

Floating Fish Feed Machine - High Efficiency Floating Fish Feed Extruder for Small Scale Production

NewsJun.10,2025

-

Premium Poultry Housing Solutions Mobile & Commercial Free Range Options

NewsJun.10,2025

-

Industrial FRP Fans Corrosion-Resistant Blades & Centrifugal Systems

NewsJun.09,2025