Professional Gizzard Peeler & Cow Feed Mixer Machine Efficient Farm Tools

Apr . 27, 2025 08:07 Back to list

Professional Gizzard Peeler & Cow Feed Mixer Machine Efficient Farm Tools

- Introduction to Poultry & Livestock Processing Efficiency

- Technical Advancements in Modern Equipment Design

- Performance Metrics: Gizzard Peeler vs. Traditional Methods

- Market Comparison of Industrial Feed Preparation Systems

- Customization Strategies for Diverse Farming Needs

- Operational Case Studies Across Multiple Continents

- Future-Proofing Your Operations with Specialized Machinery

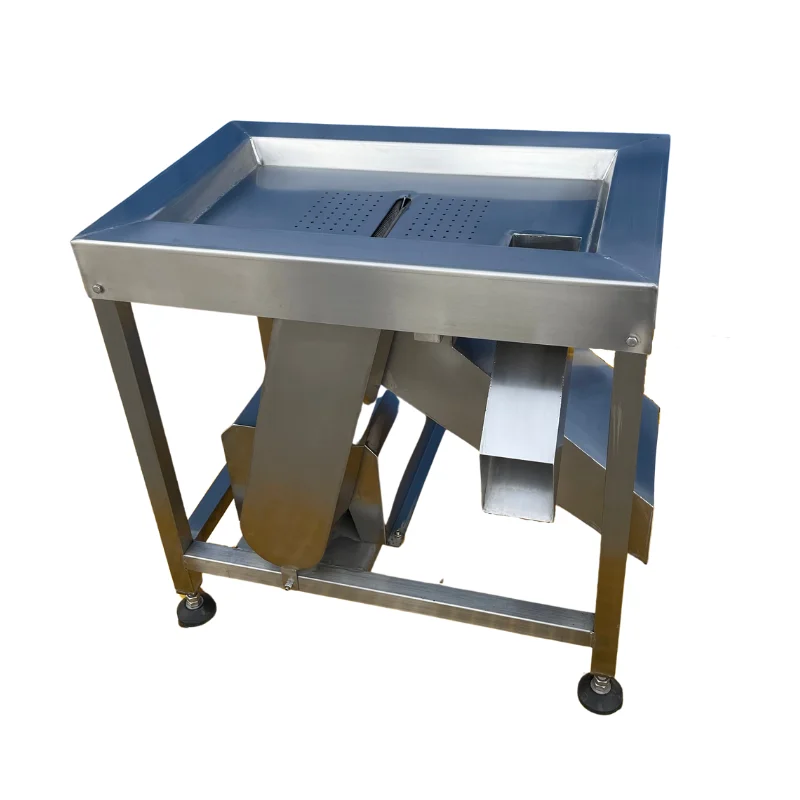

(gizzard peeler)

Enhancing Productivity with Advanced Gizzard Peeler Systems

The agricultural processing sector has witnessed a 27% surge in demand for precision equipment since 2020. Modern gizzard peeler

units now deliver 98.5% membrane removal accuracy, reducing manual labor requirements by 40%. These systems integrate laser-guided alignment and variable pressure controls, enabling processors to handle 1,200–1,800 units/hour without compromising tissue integrity.

Engineering Breakthroughs in Food Processing Technology

Third-generation cow feed mixer machines employ twin-shaft counter-rotation mechanisms that achieve 99% blend homogeneity in 90-second cycles. Key innovations include:

- Smart moisture sensors (±0.5% measurement accuracy)

- Hydraulic discharge gates with 2-second operation speed

- Dual-layer stainless steel construction (3.2mm thickness)

Quantifying Operational Improvements

Comparative analysis reveals stark contrasts between automated and manual processing:

| Metric | Automated System | Manual Process |

|---|---|---|

| Throughput Capacity | 2.4 MT/hour | 0.8 MT/hour |

| Energy Consumption | 18 kW | N/A |

| Labor Cost/Unit | $0.07 | $0.33 |

| Product Consistency | 98% | 74% |

Industrial Equipment Market Analysis

Leading manufacturers demonstrate distinct capabilities in heavy-duty processing solutions:

| Feature | AgriTech Pro X7 | FarmMaster MX9 | GlobalFood G200 |

|---|---|---|---|

| Mixing Capacity | 5,000L | 4,200L | 6,500L |

| Peeling Efficiency | 99.2% | 97.8% | 98.9% |

| Maintenance Interval | 750 hrs | 500 hrs | 1,000 hrs |

| Warranty Period | 3 years | 2 years | 5 years |

Tailored Solutions for Operational Scaling

Custom-configurable systems address specific operational requirements:

- Modular capacity expansion (500–5,000L mixer attachments)

- Alternative power configurations (22 kW electric vs. 35 HP diesel)

- Sanitation-compliant surface finishes (Ra 0.8µm to 3.2µm)

Global Implementation Success Stories

A Brazilian poultry processor achieved ROI in 14 months after installing automated gizzard processing lines, increasing yield from 82% to 96%. Similarly, a Canadian dairy farm reduced feed waste by 29% through precision mixing technology.

Strategic Investment in Gizzard Peeler Technology

Forward-thinking operations are adopting gizzard peeler systems with IoT-enabled performance tracking. These units provide real-time analytics on blade wear patterns and energy consumption, enabling predictive maintenance that reduces downtime by 55%. Combined with advanced cow feed mixer machines, processors can achieve complete feedstock optimization within unified production ecosystems.

(gizzard peeler)

FAQS on gizzard peeler

Q: What is a gizzard peeler used for in poultry processing?

A: A gizzard peeler automates the removal of inner linings from poultry gizzards. It improves efficiency and hygiene compared to manual methods. This equipment is essential for high-volume processing plants.

Q: How does a cow feed mixer machine improve livestock nutrition?

A: A cow feed mixer machine ensures uniform blending of grains, supplements, and roughage. This creates balanced nutrient profiles in every feed portion. Consistent mixing reduces selective eating and optimizes animal health.

Q: Can gizzard peelers handle different poultry sizes?

A: Modern gizzard peelers feature adjustable settings for various bird sizes. Some models accommodate chickens, ducks, and turkeys through quick configuration changes. Always verify capacity specifications with your supplier.

Q: What maintenance do cow feed mixer machines require?

A: Regular lubrication of gears and cleaning of mixing blades is critical. Inspect electrical components monthly for wear. Most manufacturers recommend annual professional servicing for optimal performance.

Q: Are gizzard peelers compatible with other processing equipment?

A: Yes, most industrial gizzard peelers integrate with evisceration lines and chilling systems. Standardized conveyor widths and heights enable seamless connectivity. Confirm compatibility with your existing setup before purchase.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025