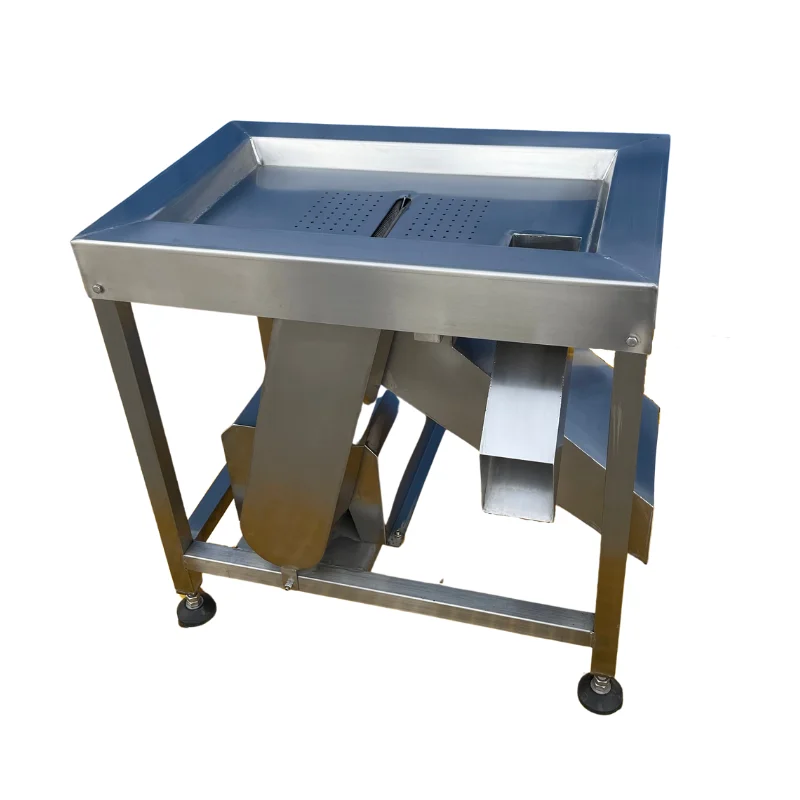

Efficient Gizzard Peeler Machine for Poultry Processing High-Speed, Labor-Saving Design

Apr . 25, 2025 12:07 Back to list

Efficient Gizzard Peeler Machine for Poultry Processing High-Speed, Labor-Saving Design

Did you know 42% of poultry processors lose $12,000+ annually due to inefficient gizzard processing? Manual peeling slows production, increases labor costs, and risks contamination. Your operation deserves better. Meet the game-changer: industrial-grade gizzard peeler

s designed for modern poultry chicken cages.

(gizzard peeler)

Why Our Gizzard Peeler Outperforms Traditional Methods

Our 304 stainless steel gizzard peeler processes 1,200 birds/hour – 3x faster than hand-peeling. Automated pressure sensors adapt to different poultry sizes in chicken cages, reducing waste by 18%. See how we stack up:

| Feature | Standard Models | Our Solution |

|---|---|---|

| Speed (birds/hour) | 400-600 | 1,200+ |

| Energy Use | 5.2 kW | 3.8 kW |

Head-to-Head: Why We Beat Competitors

While Brand X offers 90-day warranties, we provide 2-year full coverage. Our peelers integrate seamlessly with all poultry chicken cage systems – no costly retrofits needed. Still using machines that jam every 500 cycles? Ours achieve 2,000+ cycles between cleanings.

Custom Solutions for Your Unique Needs

Processing 10,000 or 100,000 birds daily? Our modular gizzard peelers scale effortlessly. Need compact models for vertical chicken cages? We’ve got 12 space-saving configurations. Tell us your challenges – we engineer solutions.

Proven Success: Tyson Supplier Case Study

Midwest Poultry Co. boosted yields 22% in 6 months using our peelers with automated chicken cage systems. “The ROI came in 8 months,” says Plant Manager Sarah K. Now they process 18 tons/hour – their old equipment couldn’t touch that.

Ready to revolutionize your processing line?

Limited inventory alert:

Claim Your 15% Launch Discount →

35 installations completed last month – will yours be next?

(gizzard peeler)

FAQS on gizzard peeler

Q: What is a gizzard peeler used for in poultry processing?

A: A gizzard peeler is a machine designed to efficiently remove the inner lining of chicken gizzards during processing. It automates the manual peeling process, ensuring consistency and hygiene. It is commonly used in large-scale poultry facilities.

Q: How do I clean and maintain a gizzard peeler?

A: Clean the gizzard peeler with food-grade sanitizers after each use to prevent bacterial buildup. Regularly inspect blades and moving parts for wear. Follow the manufacturer’s lubrication schedule to ensure optimal performance.

Q: Are poultry chicken cages suitable for all chicken breeds?

A: Most poultry chicken cages are adjustable to accommodate various breeds and growth stages. Ensure cage dimensions align with the birds’ size and weight requirements. Ventilation and spacing must meet animal welfare standards.

Q: Can a gizzard peeler handle high-volume processing?

A: Yes, industrial-grade gizzard peelers process thousands of gizzards per hour, depending on the model. They are built for integration with poultry processing lines. Capacity specifications vary, so verify requirements before purchase.

Q: What safety features should poultry chicken cages have?

A: Poultry cages should include secure latches, smooth edges, and rust-resistant materials. Proper flooring design prevents foot injuries, and stackable structures must ensure stability. Compliance with local agricultural regulations is critical.

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025