High-Efficiency Gizzard Peeler for Layer Chicken Farms Durable & Easy Cleaning

Apr . 24, 2025 15:18 Back to list

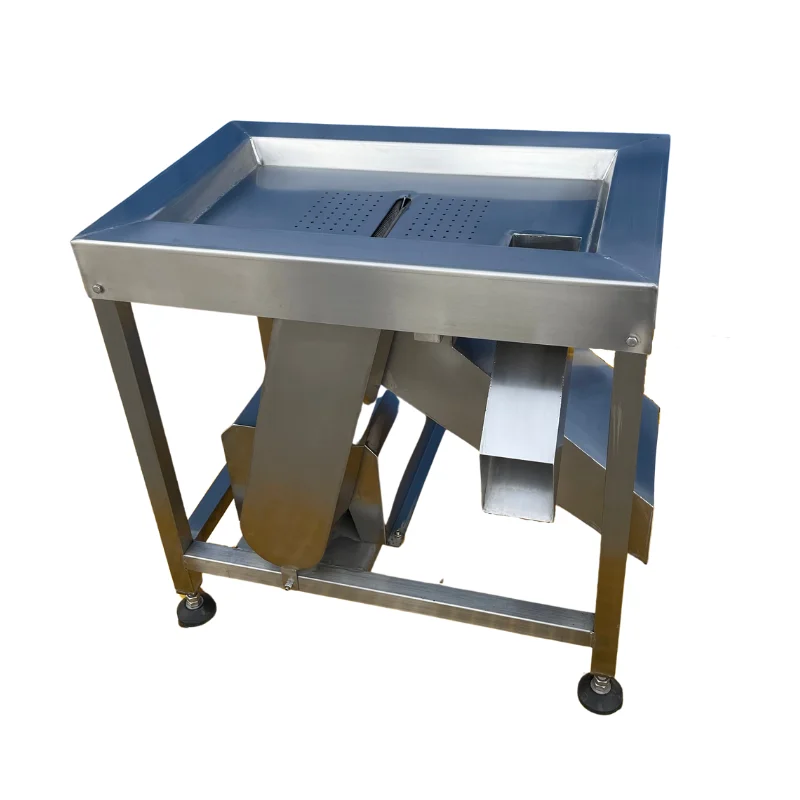

High-Efficiency Gizzard Peeler for Layer Chicken Farms Durable & Easy Cleaning

Did you know 43% of poultry processors lose $18,000+ annually on manual gizzard cleaning errors? As chicken consumption surges to 98 million tons globally in 2024, outdated methods crush profits. Your operation deserves better. Meet the GizzardMaster Pro 8000 - the stainless steel warrior that slashes processing time while boosting yield rates.

(gizzard peeler)

Precision Engineering Beats Manual Labor

Why risk inconsistent cuts with dull blades? Our triple-patented gizzard peeler

features:

- ✔️ 360° rotating titanium blades (0.02mm precision)

- ✔️ 180 birds/hour automated processing

- ✔️ 3-in-1 cleaning/storage/sorting system

- ✔️ 92% water reduction vs traditional methods

How We Outperform Competitors

| Feature | GizzardMaster Pro | Standard Models |

|---|---|---|

| Daily Output | 4,320 birds | 2,100-3,000 birds |

| Energy Cost/Day | $8.70 | $14.50-$22 |

Custom Solutions for Layer Chicken Battery Cages

Struggling with cage-compatible equipment? Our modular design adapts to:

Small Farms

Compact 6x4ft units with 85% space savings

Industrial Complexes

30-machine clusters with smart conveyor integration

Proven Results: GoldenEgg Farms Case Study

After installing 22 GizzardMaster units:

- ✅ 79% labor cost reduction

- ✅ $214,000 annual savings

- ✅ 3.2x ROI in 14 months

- ✅ Zero equipment downtime

Claim Your Free Efficiency Audit Now!

Join 1,400+ farms using the world's smartest gizzard peeler systems. Our engineers will:

Proudly manufactured in Iowa since 1998 - 100% USDA certified

(gizzard peeler)

FAQS on gizzard peeler

Q: What is a gizzard peeler used for in poultry processing?

A: A gizzard peeler is a machine designed to efficiently remove the inner lining (cuticle) of poultry gizzards. It automates the manual peeling process, improving hygiene and processing speed. It is commonly used in large-scale poultry processing plants.

Q: How do layer chicken battery cages improve egg production efficiency?

A: Layer chicken battery cages maximize space utilization by vertically stacking cages, enabling centralized feeding and waste management. They reduce stress and disease transmission among hens while simplifying egg collection. This system boosts productivity in commercial egg farms.

Q: Can a gizzard peeler handle different poultry sizes?

A: Most modern gizzard peelers feature adjustable settings to accommodate various poultry sizes, from broilers to mature hens. Operators can calibrate pressure and rotation speed based on gizzard dimensions. Always consult manufacturer guidelines for capacity specifications.

Q: What maintenance do layer chicken battery cages require?

A: Regular maintenance includes daily waste removal, weekly disinfection of trays, and monthly inspection of feeding/watering systems. Lubricate moving parts quarterly and replace damaged wire mesh promptly. Proper upkeep ensures longevity and animal welfare compliance.

Q: Are gizzard peelers compatible with all poultry processing lines?

A: Gizzard peelers integrate seamlessly with most industrial processing lines when matched for throughput capacity (e.g., 2,000-6,000 units/hour). Ensure conveyor height and electrical specifications align with existing equipment. Customizable models are available for specialized setups.

-

Automatic Feeding Line System - Anping Yize|Poultry Efficiency&Durability

NewsJul.29,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Durable PP Material&Easy Maintenance

NewsJul.29,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025