floating fish feed plant manufacturer

Nov . 19, 2024 17:48 Back to list

floating fish feed plant manufacturer

The Importance of Floating Fish Feed Plants A Comprehensive Look at Manufacturers

In the aquaculture industry, the demand for high-quality fish feed has escalated significantly. This has led to the emergence of specialized floating fish feed plants, which play a crucial role in ensuring the sustainable growth of fish and the overall efficiency of aquaculture businesses. Manufacturers in this field are equipped with advanced technology and expertise, enabling them to produce premium floating fish feeds that cater to the nutritional needs of various fish species.

The Role of Floating Fish Feed

Floating fish feed is essential for maintaining healthy aquatic ecosystems. Unlike sinking feed, which can dissolve and pollute water, floating pellets allow fish to forage naturally while providing a visual cue for feeding. This not only reduces waste but also promotes better water quality, essential for the growth and wellbeing of fish. Floating feeds are designed to float on the water surface, making it easier for fish to access them, and ensuring that the feed remains intact for extended periods.

The Process of Producing Floating Fish Feed

Manufacturers of floating fish feed engage in a meticulous production process that involves several key steps

1. Ingredient Selection The first step is the selection of high-quality raw materials such as fish meal, soybean meal, vitamins, and minerals. These ingredients are chosen based on the specific nutritional requirements of the target fish species.

2. Grinding and Mixing Once the raw materials are selected, they are ground into fine particles and thoroughly mixed to ensure uniform distribution of nutrients. This step is crucial as it affects the pellet quality and the overall digestibility of the feed.

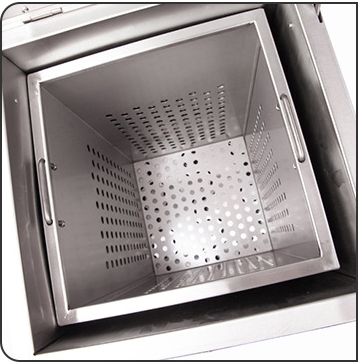

3. Extrusion The mixed feed is then subjected to extrusion, where it's pushed through a machine under high temperature and pressure. This process not only shapes the feed into pellets but also cooks the ingredients, enhancing their nutritional value and palatability.

4. Drying and Cooling After extrusion, the pellets are dried to remove excess moisture and then cooled down. This step is vital to ensure the longevity and stability of the feed, preventing spoilage during storage.

floating fish feed plant manufacturer

5. Coating (if required) In some cases, manufacturers may choose to coat the floating pellets with oils or attractants to enhance flavor and increase palatability for fish.

6. Packaging and Distribution Finally, the finished product is packaged and distributed to aquaculture businesses. Efficient distribution channels are essential to ensure that the feed reaches farms promptly and in optimal condition.

Advantages of Working with Professional Manufacturers

Partnering with a reputable floating fish feed plant manufacturer offers numerous advantages

- Quality Assurance Established manufacturers adhere to strict quality control measures, ensuring that the feed produced meets rigorous standards. This is crucial for the health of fish and the profitability of aquaculture operations.

- Customization Many manufacturers offer custom formulations tailored to the specific needs of the client. This can include targeting particular fish species, growth stages, or production objectives.

- Cost Efficiency By sourcing feed from professional manufacturers, fish farmers can often reduce their overall costs due to bulk purchasing and consistent quality. High-quality feed leads to better growth rates, reducing the time it takes to reach market size.

- Sustainability Practices Many modern feed manufacturers are committed to sustainable practices, sourcing ingredients responsibly and minimizing environmental impact. This dedication is essential as the world faces increasing pressure to optimize food production systems.

Conclusion

The establishment of floating fish feed plants has revolutionized the aquaculture industry, providing fish farmers with the tools they need to cultivate healthy and vibrant aquatic life. Manufacturers not only ensure high-quality feed production but also contribute to the sustainable practices necessary for the industry's future. As the demand for seafood continues to rise globally, the role of floating fish feed plants and their manufacturers will become increasingly vital in promoting a thriving aquaculture sector. By focusing on innovation and quality, these manufacturers are shaping the future of fish farming and contributing significantly to global food security.

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025