feed pelletizer machines

Dec . 28, 2024 04:06 Back to list

feed pelletizer machines

Understanding Feed Pelletizer Machines Revolutionizing Animal Feed Production

In the livestock and aquaculture industries, the demand for high-quality animal feed is continuously increasing. One essential piece of equipment that plays a crucial role in producing this feed is the feed pelletizer machine. These machines are designed to convert various raw materials into pellets, which are not only nutritious but also easier for animals to digest. This article will explore the functionality, benefits, and different types of feed pelletizer machines.

What is a Feed Pelletizer Machine?

A feed pelletizer machine is a piece of equipment used to compress and reshape raw ingredients, such as grains, protein sources, and other additives, into small, uniform pellets. The process of pelletization involves several steps, including grinding, mixing, conditioning, and finally, pelleting. The end result is a more manageable product that minimizes waste and enhances feed efficiency.

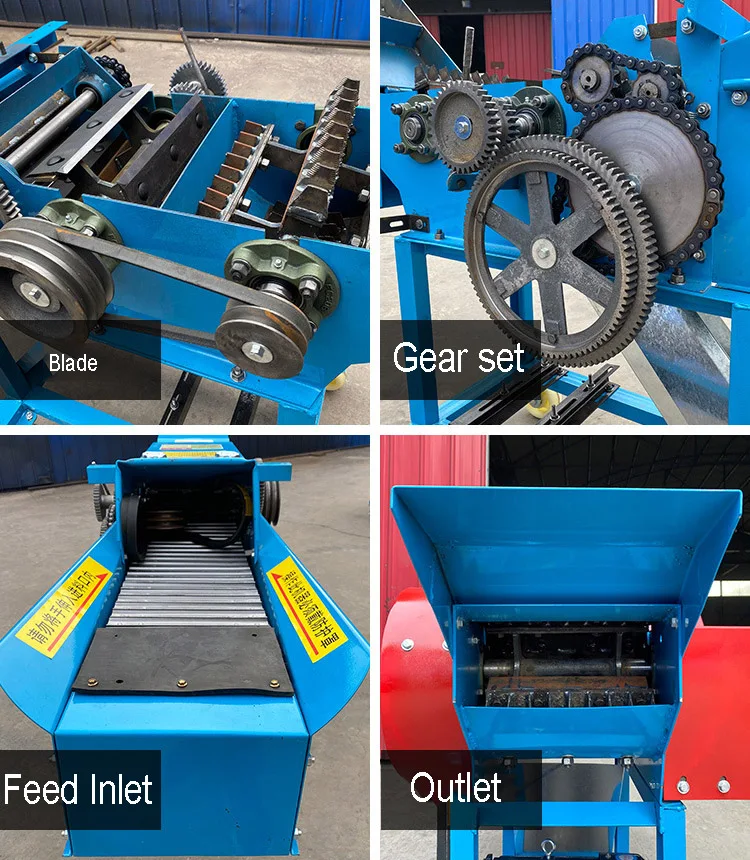

The key components of a feed pelletizer include the feed hopper, conditioner, pellet mill, die, and cutter. The process begins with the raw materials being fed into the hopper. They are then mixed and conditioned with moisture and heat before being pushed through the die in the pellet mill, where they are compressed into uniform pellets. Finally, the pellets are cut into the desired length before being transported for cooling and packaging.

Benefits of Feed Pelletizer Machines

1. Improved Nutritional Value Pelletizing raw materials helps in retaining nutrients, making the feed more digestible. The compact form also allows for better nutrient distribution.

2. Reduced Feed Wastage Pellets are less likely to be wasted compared to loose feed, as they are more appealing and easier for animals to consume. This leads to better feed conversion ratios.

3. Enhanced Palatability The pelleting process includes heat treatment that can enhance the flavor and aroma of the feed, making it more attractive to animals.

4. Longer Shelf Life Pellets are generally more stable and less prone to spoilage than loose feed. This helps in maintaining feed quality over time.

feed pelletizer machines

5. Easier Handling and Transportation Pellets are more compact, making them easier to store, transport, and handle compared to bulk feed materials.

6. Customization Feed pelletizers can be adjusted to produce pellets of different sizes and formulations, allowing producers to tailor feed to the specific dietary needs of their animals.

Types of Feed Pelletizer Machines

There are several types of feed pelletizer machines available in the market, catering to different production needs

1. Flat Die Pelletizers These machines are suitable for small-scale production and typically used for making pellets for poultry, rabbits, and fish. They operate at lower pressures and temperatures compared to ring die pelletizers.

2. Ring Die Pelletizers Commonly used for larger-scale operations, these machines are ideal for producing high-quality livestock feed. They offer a continuous process with high efficiency and can handle a larger variety of raw materials.

3. Mobile Pelletizers These versatile machines can be moved to different locations, allowing for on-site production. They are particularly useful for farmers who want to produce high-quality feed from homegrown raw materials.

4. Multi-functional Pelletizers Some machines can produce different forms of feed, such as pellets, crumbs, or meal, making them suitable for various animal species and feeding systems.

Conclusion

Feed pelletizer machines have transformed the way animal feed is produced, enhancing nutritional value, reducing wastage, and improving the overall quality of feed. As the demand for efficient and effective animal nutrition continues to rise, these machines will play an even more significant role in the industry. Investing in a suitable feed pelletizer not only leads to improved feed efficiency but also contributes to better livestock health and productivity. For farmers and feed producers, understanding this technology is essential for maintaining a competitive edge in the ever-evolving agricultural landscape.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025