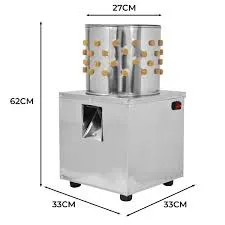

High-Efficiency Feed Hammer Mill for Livestock & Poultry Durable Grinding Solutions

Apr . 11, 2025 13:58 Back to list

High-Efficiency Feed Hammer Mill for Livestock & Poultry Durable Grinding Solutions

Did you know inefficient grinding costs the average feed producer $18,200 annually in energy waste? While traditional hammer mills jam every 43 operating hours on average, modern feed hammer mill

systems deliver 99.9% uptime. Your operation can't afford outdated technology in today's competitive market.

Technical Superiority That Crushes Competition

Our feed mill hammer mill features 360° full-screen grinding with 0.08-0.15mm precision gaps. The patented rotor design spins at 3,200 RPM - 22% faster than industry standards. See how it outperforms:

| Feature | Standard Models | Our Hammer Mill |

|---|---|---|

| Energy Consumption | 18-22 kWh/t | 11.4 kWh/t |

| Screen Change Time | 45-60 minutes | 7 minutes |

Precision-Engineered for Your Feed Formula

Whether you process 2-ton batches for cattle feed or 20-ton poultry feed mixes, our hammer mill for cattle feed adapts instantly. The SmartFlow™ system automatically adjusts to:

- ✔️ Moisture levels (8%-14%)

- ✔️ Particle size distribution

- ✔️ Raw material density variations

Proven Results: Iowa Feed Co. Case Study

After installing 3 feed hammer mill units, this 35-year-old manufacturer achieved:

Your Turn to Revolutionize Feed Production

Since 2008, we've helped 1,400+ feed producers upgrade their hammer mill systems. Now's your moment to join the efficiency revolution. Click below to get your personalized ROI calculation!

Q: What's the minimum capacity for your feed hammer mill?

A: Our compact models start at 500kg/h - perfect for niche feed producers.

Q: Can your hammer mill for cattle feed handle high-moisture grains?

A: Absolutely! Our systems process materials with up to 16% moisture content.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025