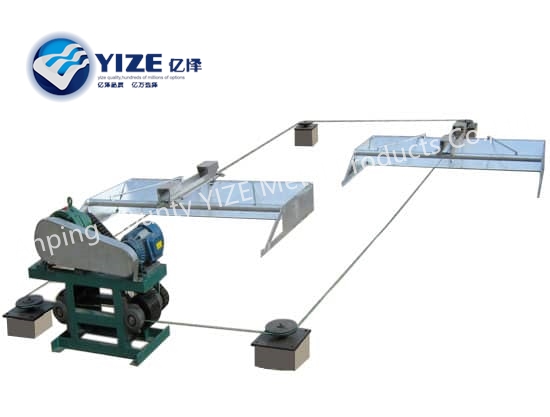

Automatic egg collecting system egg collection machine egg picking machine for layer chicken cage

Feb . 14, 2025 18:44 Back to list

Automatic egg collecting system egg collection machine egg picking machine for layer chicken cage

In the ever-evolving agricultural landscape, the role of a feed grinder has become crucial for farmers seeking efficiency and productivity in livestock management. As someone who has spent years immersed in agricultural machinery, I can attest to the transformative power of a high-quality feed grinder.

From a professional standpoint, the authority of a feed grinder in a farm setting is undeniable. It not only impacts the quantity and quality of feed produced but also influences the overall management practices on the farm. An efficient feed grinder reduces waste significantly by producing uniform particle sizes, ensuring that livestock receive balanced nutrition without the risk of feed separation. This leads to healthier animals and, subsequently, better production outcomes, whether it's milk, eggs, or meat. Building trust with feed grinders comes from consistent performance and longevity. Durability is a must, as these machines operate in demanding environments, often exposed to dust and moisture. The materials used in construction—such as stainless steel for hygiene and corrosion resistance—are key indicators of a grinder's reliability. Regular maintenance, including the sharpening of blades and ensuring the integrity of the motor, extends the life of the grinder, safeguarding it as an invaluable asset on the farm. For anyone exploring the acquisition of a feed grinder, it's essential to rely not only on product specifications but also on real-world reviews and testimonials from other farmers. Engaging with community forums or attending agricultural expos can provide invaluable insights into how different models perform under varied conditions. The shared experiences of seasoned users can inform new buyers about potential pitfalls and the best practices for maintenance and operation. In conclusion, the strategic use of a feed grinder is an investment that pays dividends across an agricultural operation. Its ability to convert raw materials into high-quality feed is indispensable in achieving efficient and cost-effective livestock management. By leveraging technical expertise and embracing innovations in grinder technology, farmers can significantly enhance their productivity and ensure the sustainability of their operations for future generations.

From a professional standpoint, the authority of a feed grinder in a farm setting is undeniable. It not only impacts the quantity and quality of feed produced but also influences the overall management practices on the farm. An efficient feed grinder reduces waste significantly by producing uniform particle sizes, ensuring that livestock receive balanced nutrition without the risk of feed separation. This leads to healthier animals and, subsequently, better production outcomes, whether it's milk, eggs, or meat. Building trust with feed grinders comes from consistent performance and longevity. Durability is a must, as these machines operate in demanding environments, often exposed to dust and moisture. The materials used in construction—such as stainless steel for hygiene and corrosion resistance—are key indicators of a grinder's reliability. Regular maintenance, including the sharpening of blades and ensuring the integrity of the motor, extends the life of the grinder, safeguarding it as an invaluable asset on the farm. For anyone exploring the acquisition of a feed grinder, it's essential to rely not only on product specifications but also on real-world reviews and testimonials from other farmers. Engaging with community forums or attending agricultural expos can provide invaluable insights into how different models perform under varied conditions. The shared experiences of seasoned users can inform new buyers about potential pitfalls and the best practices for maintenance and operation. In conclusion, the strategic use of a feed grinder is an investment that pays dividends across an agricultural operation. Its ability to convert raw materials into high-quality feed is indispensable in achieving efficient and cost-effective livestock management. By leveraging technical expertise and embracing innovations in grinder technology, farmers can significantly enhance their productivity and ensure the sustainability of their operations for future generations.

Latest news

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025