exhaust fan for laser engraver

Sep . 10, 2024 17:24 Back to list

exhaust fan for laser engraver

The Importance of Exhaust Fans for Laser Engravers

Laser engraving has become increasingly popular in various industries, from personalized gifts to intricate designs on industrial materials. However, the process generates significant amounts of smoke, fumes, and potentially harmful particles that can compromise both the quality of the engraving and the health of the operator. This is where the role of exhaust fans becomes critical.

The Importance of Exhaust Fans for Laser Engravers

Additionally, an exhaust fan ensures that the engraved materials retain high quality. The buildup of smoke and particles on the surface during the engraving process can lead to discoloration or residue, affecting the final product's appearance. By maintaining proper air circulation and removing these byproducts, an exhaust fan helps preserve the detail and clarity of the engravings.

exhaust fan for laser engraver

Choosing the right exhaust fan for a laser engraver involves considering several factors, including the size of the workspace, the type of materials being engraved, and the specific requirements of the laser machine. A fan with a sufficient CFM (cubic feet per minute) rating is essential to ensure adequate airflow. It’s also crucial to select a fan designed to filter out the specific particles generated during the engraving process, such as activated carbon filters, which can trap chemical vapors effectively.

For optimal performance, the exhaust fan should be placed close to the laser engraver. This positioning helps facilitate efficient removal of smoke and fumes right at the source. Regular maintenance of the exhaust system is also important to ensure consistent operation, involving the cleaning and replacement of filters as needed.

In conclusion, incorporating an exhaust fan into your laser engraving setup is not just a recommendation but a necessity for anyone serious about quality and safety. By investing in a proper ventilation system, users can enhance their engraving process, protect their health, and ensure that their products meet the highest standards. With the right approach to ventilation, laser engraving can continue to be a rewarding and innovative craft.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

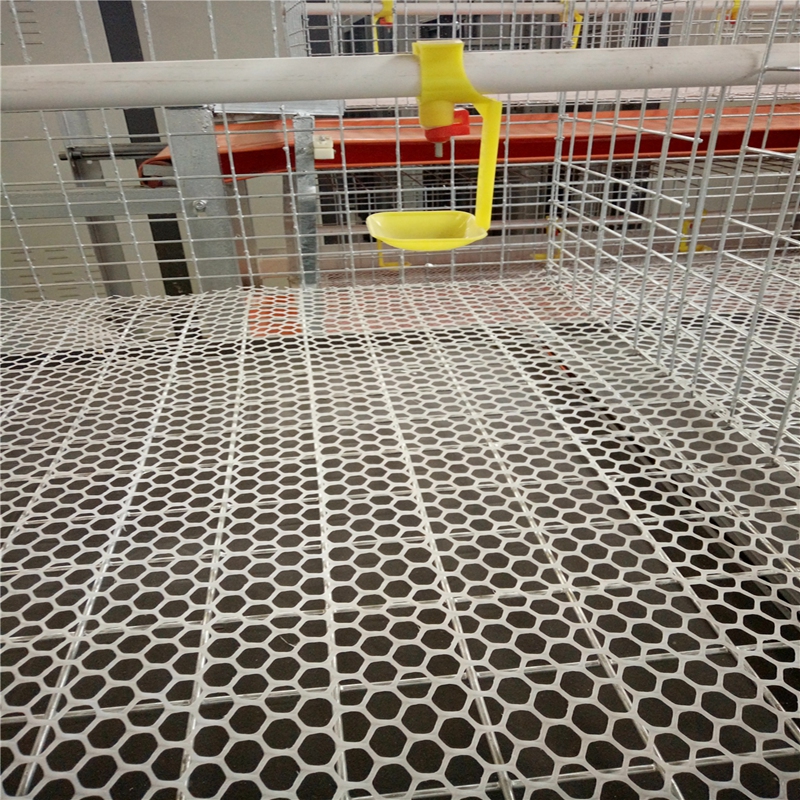

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025