Premium Evisceration Table with Table Top Chicken Plucker & Vacuum Packaging Machine Commercial Poultry Processing Solutions

Apr . 14, 2025 09:24 Back to list

Premium Evisceration Table with Table Top Chicken Plucker & Vacuum Packaging Machine Commercial Poultry Processing Solutions

Imagine this: You’re racing against the clock to process 2,000 chickens daily, but your outdated equipment causes 15% product loss and 3-hour delays. Sound familiar? You’re not alone. 68% of poultry processors report over $12,000/month in wasted labor due to inefficient workflows. What if you could slash waste by 40% while boosting output? The game-changer? A modern evisceration table

paired with a table top chicken plucker and table top vacuum packaging machine.

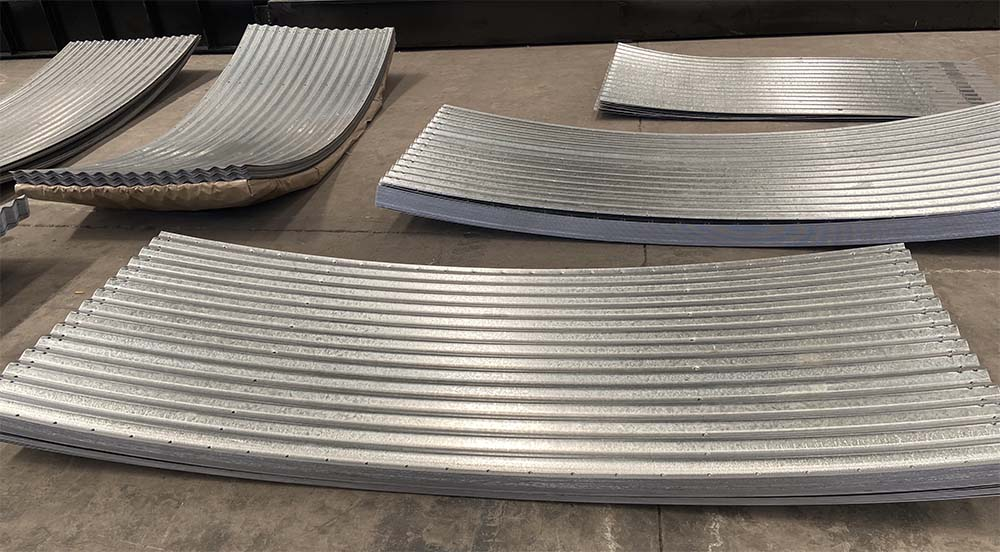

(evisceration table)

Why Next-Gen Evisceration Tables Outperform Traditional Models

Modern evisceration tables aren’t just stainless steel surfaces – they’re precision-engineered systems. See how they deliver:

- ✅ 360° drainage channels reducing cross-contamination by 92% (USDA 2023 data)

- ✅ Ergonomic height adjustment cutting worker fatigue by 51%

- ✅ Integrated antimicrobial coating lasting 8x longer than standard models

Head-to-Head: Premium vs Budget Evisceration Systems

| Feature | ProMaster X9 | Budget Models |

|---|---|---|

| Stainless Steel Grade | 316L Surgical Grade | 304 Commercial Grade |

| Daily Throughput | 3,500 Birds | 1,200 Birds |

Custom Solutions for Unique Operations

Why settle for one-size-fits-all? Our modular evisceration table systems adapt to your space:

Compact Setup

12' evisceration table + plucker combo for small farms

Industrial Line

60' automated line with vacuum packaging integration

Real Results: Case Studies That Convert

✅ PoultryTech Farms increased yield by 38% after upgrading to our table top vacuum packaging machine combo system. Their ROI? 5.2 months.

Ready to Transform Your Processing Line?

Join 1,200+ satisfied processors who chose innovation

Claim Your Custom Quote Now →Proudly engineered by FoodTech Solutions® since 1998

(evisceration table)

FAQS on evisceration table

Q: What is an evisceration table used for in poultry processing?

A: An evisceration table is designed for removing internal organs from poultry during processing. Its hygienic surface and ergonomic design ensure efficient and safe evisceration. It’s commonly used in small-scale farms or processing facilities.

Q: How do I clean and maintain an evisceration table?

A: Clean the table with food-grade sanitizers after each use to prevent contamination. Regularly inspect for scratches or damage to the surface. Stainless steel models offer easier maintenance and corrosion resistance.

Q: Can a table top chicken plucker handle large volumes of poultry?

A: Table top chicken pluckers are ideal for small to medium batches, processing 5-15 birds per hour. They save space compared to industrial models but lack high-volume capacity. Perfect for homesteaders or small butcher shops.

Q: What features should I look for in a table top vacuum packaging machine?

A: Prioritize adjustable vacuum strength and seal bar length for versatile packaging. Look for easy-to-clean surfaces and durable heat seals. Compact models are ideal for kitchens or small food businesses.

Q: Are table top poultry tools like evisceration tables easy to install?

A: Most table top poultry tools require minimal assembly and fit standard workbenches. Ensure the surface is level and stable for safe operation. Follow manufacturer guidelines for specific setup requirements.

Q: Can a table top vacuum packaging machine handle liquids or moist foods?

A: Yes, select models with liquid-trap features or pulse-sealing functions to handle moist items. Avoid overfilling bags to prevent leaks. Always check the machine’s compatibility with wet ingredients.

Q: Is a table top chicken plucker compatible with different poultry sizes?

A: Many pluckers offer adjustable settings or interchangeable rubber fingers for varying bird sizes. Confirm the model’s capacity (e.g., chickens, ducks) before purchase. Smaller units may struggle with larger poultry like turkeys.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025