Electric Scalder for Efficient Animal Processing and Enhanced Meat Quality

Nov . 30, 2024 20:58 Back to list

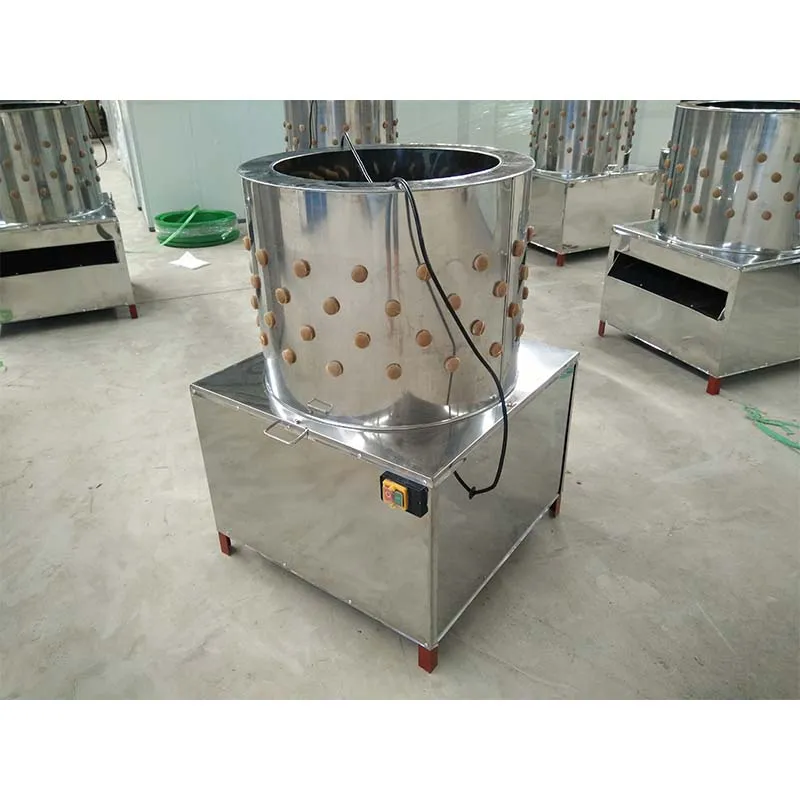

Electric Scalder for Efficient Animal Processing and Enhanced Meat Quality

The Electric Scalder Revolutionizing Poultry Processing

The poultry industry has seen significant advancements in technology over the past few decades, aiming to enhance efficiency, improve animal welfare, and ensure food safety. One of the most groundbreaking inventions in this sector is the electric scalder. This innovative equipment has transformed the way poultry is processed, offering numerous advantages over traditional scalding methods.

Understanding Electric Scalding

Electric scalding is a method used in the poultry processing industry to prepare birds for plucking. Traditionally, scalding involved immersing birds in hot water to loosen feathers. However, this process could be inconsistent, leading to uneven feather removal and potential damage to the bird’s skin. The electric scalder, on the other hand, utilizes electric heating elements to raise the temperature of the water quickly and maintain it at a precise level, ensuring uniform heating and scalding of the birds.

Advantages of Electric Scalders

1. Efficiency and Productivity Electric scalders are designed for high-volume processing, significantly increasing throughput. Their ability to heat water rapidly allows for continuous operations, reducing downtime and enhancing overall productivity. This efficiency is crucial in meeting the growing demand for poultry products in global markets.

2. Consistent Results The uniform heating provided by electric scalders results in consistent scalding temperatures, which is essential for effective feather removal. This consistency not only improves the quality of the processed birds but also minimizes the risk of scalding injuries, which can occur with inconsistent temperatures in traditional methods.

3. Energy Efficiency Electric scalders are more energy-efficient compared to their gas-fired counterparts. They require less energy to maintain optimal operating temperatures, which can significantly lower operational costs for poultry processing plants. As the industry moves toward more sustainable practices, the energy efficiency of electric scalders makes them an attractive option.

electric scalder

4. Improved Animal Welfare The humane treatment of animals during processing is a growing concern among consumers and industry regulators. Electric scalders can be adjusted to achieve optimal temperatures that minimize stress and suffering for the birds. By improving the scalding process, these machines contribute to better animal welfare outcomes.

5. Enhanced Food Safety One of the primary goals of poultry processing is to ensure that the final product is safe for consumption. Electric scalders can help achieve this by ensuring that the scalding process is consistent and effective in killing bacteria on the skin of the birds. This reduces the risk of contamination and enhances the safety of poultry products, addressing consumer concerns about foodborne illness.

The Future of Electric Scalding Technology

As technology continues to evolve, the electric scalder is likely to undergo further enhancements. Innovations such as digital monitoring systems, automated controls, and integration with other processing equipment will continue to improve the efficiency and effectiveness of electric scalder operations. The incorporation of sensors that monitor water temperature and quality can help optimize the scalding process, ensuring that each batch of birds is processed under ideal conditions.

Moreover, the rise of automation in poultry processing suggests that electric scalders could become even smarter, with the potential for real-time data analysis and adjustments to improve performance. As the industry faces increasing pressure to enhance productivity and sustainability, the continued evolution of the electric scalder will play a crucial role in addressing these challenges.

Conclusion

The introduction of the electric scalder has revolutionized poultry processing, offering a myriad of benefits that enhance efficiency, improve animal welfare, and ensure food safety. As the industry moves towards more sustainable and humane practices, the electric scalder stands out as a pivotal technology that will shape the future of poultry processing. With ongoing innovations, it is poised to remain a vital component in the quest for excellence in the poultry industry.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025