Electric Chicken Scalding Machine for Efficient and Humane Poultry Processing Solution

Nov . 18, 2024 15:55 Back to list

Electric Chicken Scalding Machine for Efficient and Humane Poultry Processing Solution

The Electric Chicken Scalder Revolutionizing Poultry Processing

In the poultry processing industry, efficiency and hygiene are paramount. Among the essential processes that ensure both aspects is the scalding of chicken. This procedure is crucial for facilitating the feather removal process, making it an indispensable step in the poultry slaughtering line. The electric chicken scalder has emerged as a game-changer in this field, offering significant improvements over traditional scalding methods.

What is an Electric Chicken Scalder?

An electric chicken scalder is a specialized piece of equipment designed to heat water to a specific temperature, typically between 140°F to 160°F (60°C to 71°C). The chicken carcasses are submerged in this hot water, which loosens the feathers, making them easier to remove during plucking. Unlike gas-powered scalders, electric scalders rely on electric heating elements, making them a safer and often more environmentally friendly option.

Efficiency and Speed

One of the most notable advantages of using an electric chicken scalder is the efficiency it brings to poultry processing. Traditional methods often require extensive manual labor and can be time-consuming. Electric scalders, on the other hand, can process large volumes of chicken rapidly, significantly reducing processing times. By automating the scalding process, poultry plants can maximize throughput, allowing them to meet the demands of a growing consumer market.

Moreover, the ability to maintain consistent water temperatures is a critical factor in the quality of scalding. Electric scalders are designed to monitor and adjust the water temperature automatically. This feature ensures that the process is not only efficient but also that it meets the required health and safety standards, resulting in better-quality meat and less risk of contamination.

Hygienic Practices

electric chicken scalder

In an industry where hygiene is of utmost importance, the electric chicken scalder offers various benefits that help maintain sanitary conditions. With electric scalders, the risk of cross-contamination is significantly reduced. These machines are often designed with easy-to-clean components and materials that resist bacteria growth, ensuring a healthier processing environment.

Additionally, the electric scalder is generally easier to maintain than its gas counterparts. This ease of maintenance extends the lifeline of the equipment, leading to cost savings over time. Regular cleaning protocols can be easily implemented, and the accuracy of temperature control helps to keep preparation areas hygienic by preventing the overcooking or undercooking of the birds.

Environmental Impact

As environmental concerns grow in the food processing industry, the electric chicken scalder also stands out as a more sustainable option. Electric scalders typically have lower carbon footprints compared to gas varieties, and advances in technology mean that they are becoming increasingly energy-efficient. Many modern units are equipped with insulation and heat recovery systems, further minimizing energy use and waste.

Furthermore, the potential for utilizing renewable energy sources adds another layer of sustainability. Facilities can harness solar power or wind energy to operate electric scalders, transforming their processes into eco-friendly operations.

Conclusion

The electric chicken scalder is revolutionizing the poultry processing industry by offering efficiency, improved hygiene, and a more sustainable approach to scalding. As consumers demand higher quality and ethically sourced meat products, the need for modern, reliable equipment has never been more critical.

Investing in electric scalding technology not only meets these demands but also prepares processing plants for the future. By prioritizing efficiency, hygiene, and sustainability, the electric chicken scalder exemplifies how innovation can elevate the standards of the poultry industry, ensuring that it can keep pace with the dynamic nature of food production and consumption.

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

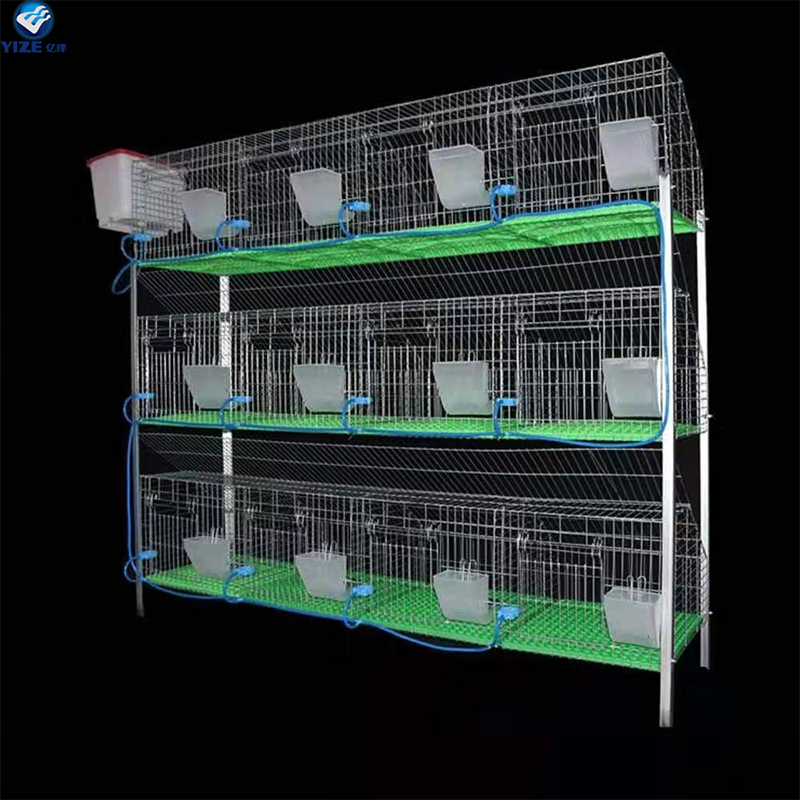

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025