Swine Equipment Farrowing Pen

Jan . 24, 2025 06:01 Back to list

Swine Equipment Farrowing Pen

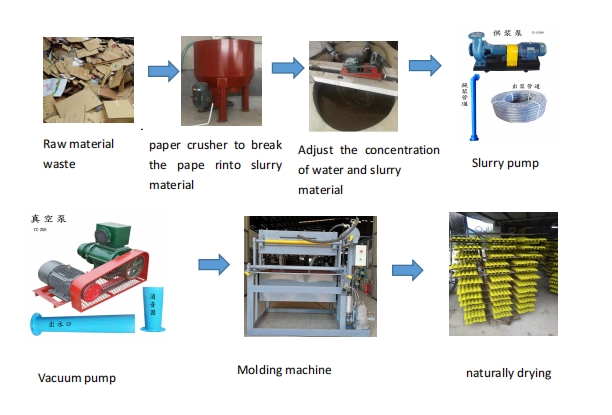

Having spent over a decade in the realm of manufacturing technology, the evolution and effectiveness of the eggs tray machine stands out as particularly noteworthy. These machines are not just about encasing delicate ovals in pre-designed pulps; they embody a marriage of precision engineering and innovative science aimed at revolutionizing packaging industries globally.

Trustworthiness in this sector hinges on consistent output and machine longevity. Reputable models are crafted from high-grade steel and durable components, undergoing rigorous stress-testing protocols to ensure reliability under continuous operation conditions. Manufacturers often provide extensive support services, including training and maintenance packages, thereby instilling confidence in businesses that their investment is safeguarded. The economic and operational advantages presented by these machines are amplified when considering their adaptability. Models vary to cater to diverse production needs, from small-scale operations focusing on artisanal egg providers to large-scale enterprises supplying international markets. This versatility means that regardless of the scale, there is a machine tailored to meet specific production demands efficiently. Furthermore, information sharing in the digital age has positioned these machines at the forefront of technological advancement. Online platforms facilitate an open exchange of user experiences and best practices, allowing operators to fine-tune their processes and achieve optimal results. The collective expertise available through these channels ensures continuous improvement and innovation, driven by real-world feedback and application. In conclusion, the evolution of the eggs tray machine epitomizes a blend of technical mastery and environmental stewardship, providing a consistent, trustworthy, and innovative solution for egg packaging worldwide. By focusing on precision, sustainability, and adaptability, these machines not only elevate the operational capabilities of agro-packaging industries but also align with the broader aim of ecological responsibility. As the demand for eggs continues to rise globally, the role of these machines will become ever more pivotal, underscoring their status as a cornerstone of modern packaging solutions.

Trustworthiness in this sector hinges on consistent output and machine longevity. Reputable models are crafted from high-grade steel and durable components, undergoing rigorous stress-testing protocols to ensure reliability under continuous operation conditions. Manufacturers often provide extensive support services, including training and maintenance packages, thereby instilling confidence in businesses that their investment is safeguarded. The economic and operational advantages presented by these machines are amplified when considering their adaptability. Models vary to cater to diverse production needs, from small-scale operations focusing on artisanal egg providers to large-scale enterprises supplying international markets. This versatility means that regardless of the scale, there is a machine tailored to meet specific production demands efficiently. Furthermore, information sharing in the digital age has positioned these machines at the forefront of technological advancement. Online platforms facilitate an open exchange of user experiences and best practices, allowing operators to fine-tune their processes and achieve optimal results. The collective expertise available through these channels ensures continuous improvement and innovation, driven by real-world feedback and application. In conclusion, the evolution of the eggs tray machine epitomizes a blend of technical mastery and environmental stewardship, providing a consistent, trustworthy, and innovative solution for egg packaging worldwide. By focusing on precision, sustainability, and adaptability, these machines not only elevate the operational capabilities of agro-packaging industries but also align with the broader aim of ecological responsibility. As the demand for eggs continues to rise globally, the role of these machines will become ever more pivotal, underscoring their status as a cornerstone of modern packaging solutions.

Next:

Latest news

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025