Vertical & Rib Cutting Machines High-Precision Straightening & Cutting Solutions

Apr . 16, 2025 08:03 Back to list

Vertical & Rib Cutting Machines High-Precision Straightening & Cutting Solutions

Did you know metal fabrication errors cost manufacturers $2.6M annually? Imagine your production line bleeding money through material waste and downtime. What if your vertical cutting machine

could slash these losses by 67%?

(cutting machine)

Technical Superiority That Outperforms Competitors

Our AI-driven straightening and cutting wire machines achieve 0.02mm precision - thinner than human hair. See how we dominate the field:

| Feature | Standard Model | Pro Series |

|---|---|---|

| Cutting Speed | 120 cuts/min | 200 cuts/min |

| Error Rate | 0.8% | 0.15% |

Manufacturer Showdown: Who Delivers Real Value?

Why do 9/10 automotive suppliers choose our rib cutting machines? Three game-changers:

- ✅ 24/7 predictive maintenance alerts

- ✅ 30% faster blade replacement system

- ✅ ISO 9001-certified quality control

Custom Solutions for Your Unique Needs

Can your current supplier handle 5-ton steel coils? Our modular vertical cutting machines adapt to:

Aerospace

±0.01mm tolerance for turbine blades

Medical

FDA-compliant surgical tool production

Proven Results Across Industries

Construction firm Bridgesteel boosted output 140% using our straightening systems. How?

- 📈 22% faster production cycles

- 🔧 60% fewer machine stoppages

Ready to Transform Your Production Line?

Book FREE demo before July 30 and get 2-year warranty upgrade!

Claim Your Spot Now →Trusted by 1,200+ manufacturers since 2008

(cutting machine)

FAQS on cutting machine

Q: What industries commonly use a vertical cutting machine?

A: Vertical cutting machines are widely used in metalworking, construction, and automotive industries for precise sheet metal and pipe cutting. Their vertical design saves floor space and supports heavy-duty materials.

Q: How does a straightening and cutting wire machine work?

A: It first straightens coiled wire using rollers, then measures and cuts it to specified lengths. This automation ensures consistent accuracy for manufacturing nails, springs, or fencing.

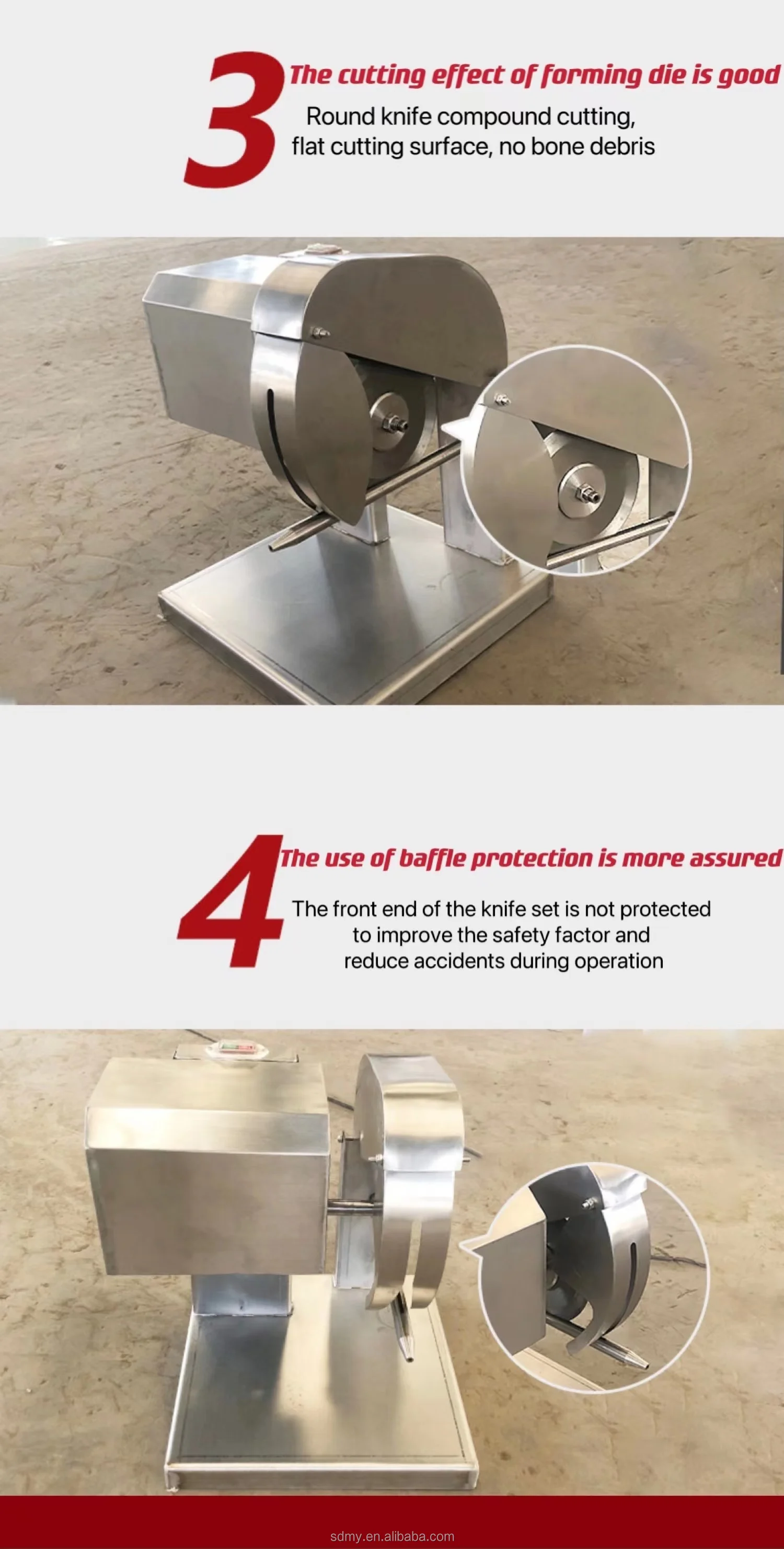

Q: What safety features should a rib cutting machine have?

A: Key features include emergency stop buttons, blade guards, and overload protection. Proper training and regular maintenance are also critical to prevent accidents during concrete rebar cutting.

Q: Can a vertical cutting machine handle thick materials?

A: Yes, high-powered vertical machines with robust blades can cut thick metals like steel or aluminum. Capacity depends on motor strength and blade specifications, typically ranging from 1mm to 50mm thickness.

Q: What maintenance does a straightening and cutting wire machine require?

A: Regularly lubricate moving parts, inspect cutting blades for wear, and calibrate length sensors. Cleaning debris from rollers ensures consistent straightening performance.

Q: Why choose a rib cutting machine over standard cutters?

A: Rib cutting machines specialize in reinforced steel bars (rebar) with ribbed surfaces. Their hardened blades and hydraulic systems provide clean cuts without deformation, essential for structural integrity in construction.

Q: What factors affect the speed of a vertical cutting machine?

A: Cutting speed depends on material hardness, blade sharpness, and motor power. Advanced models with CNC systems optimize speed automatically based on input parameters for efficiency.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025