Precision Vertical, Wire & Rib Cutting Machines High-Efficiency Tools

Apr . 26, 2025 09:34 Back to list

Precision Vertical, Wire & Rib Cutting Machines High-Efficiency Tools

- Overview of Cutting Machine Applications

- Technical Advantages Across Machine Types

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Industrial Requirements

- Operational Data Impact Analysis

- Implementation Case Studies

- Sustainable Development in Cutting Technology

(cutting machine)

Essential Innovations in Modern Cutting Equipment

Industrial cutting systems have evolved from basic mechanical tools to computer-controlled precision instruments. The global market for vertical cutting machine

s alone reached $4.2 billion in 2023, with 6.8% annual growth projected through 2030. Advanced models now integrate IoT sensors that reduce material waste by 18-22% compared to conventional units.

Engineering Superiority in Cutting Systems

Contemporary straightening and cutting wire machines demonstrate three critical improvements:

- 56% faster blade replacement cycles through modular designs

- ±0.02mm positioning accuracy via linear servo motors

- 37% energy reduction using adaptive power management

These advancements enable rib cutting machines to process composite materials at 12m/min while maintaining surface finish below Ra 1.6μm.

Manufacturer Competency Evaluation

| Vendor | Cut Speed (mm/s) | Precision (±mm) | Energy Use (kW) | Price Range |

|---|---|---|---|---|

| AlphaCut ProSeries | 420 | 0.015 | 5.2 | $82,000-115,000 |

| PrecisionEdge V9 | 380 | 0.018 | 4.8 | $74,500-102,000 |

| WireMaster 360 | 460 | 0.012 | 5.5 | $91,000-128,000 |

Adaptive Configuration Strategies

Customization options address specific operational demands:

- Automotive Sector: 8-axis synchronization for curved surface trimming

- Construction: Tungsten carbide blades cutting 8-12mm rebar

- Food Processing: Hygienic stainless steel models with CIP compatibility

Efficiency Metrics and Cost Benefits

Implementation data from 142 manufacturing plants reveals:

- 19-24% reduction in production downtime

- $7.8/meter lowered operational cost for wire processing

- 14-month average ROI period for automated systems

Industry-Specific Deployment Examples

A tier-1 auto parts supplier achieved 92% material utilization using vertical cutting machines with real-time thickness monitoring. In textile manufacturing, specialized rib cutting units increased output by 37% while maintaining pattern consistency across 18-month production cycles.

Advancing Cutting Machine Sustainability

Recent models incorporate regenerative braking systems that recover 12-15% of operational energy. Manufacturers now offer carbon-neutral configurations, reducing lifetime emissions by 28 metric tons per machine. The integration of AI-driven predictive maintenance extends equipment lifespan by 40% compared to 2020 benchmarks.

(cutting machine)

FAQS on cutting machine

Q: What is a vertical cutting machine used for?

A: A vertical cutting machine is designed to cut materials like metal, plastic, or fabric vertically with precision. It is ideal for applications requiring straight, high-accuracy cuts and is commonly used in industrial manufacturing.

Q: How does a straightening and cutting wire machine work?

A: This machine first straightens coiled wire using rollers, then cuts it to specified lengths. It ensures uniform straightness and precise measurements, making it essential for industries like construction and automotive.

Q: What industries use rib cutting machines?

A: Rib cutting machines are primarily used in textile and apparel industries to trim fabric ribs or elastic bands. They ensure clean, efficient cuts while maintaining material integrity during high-volume production.

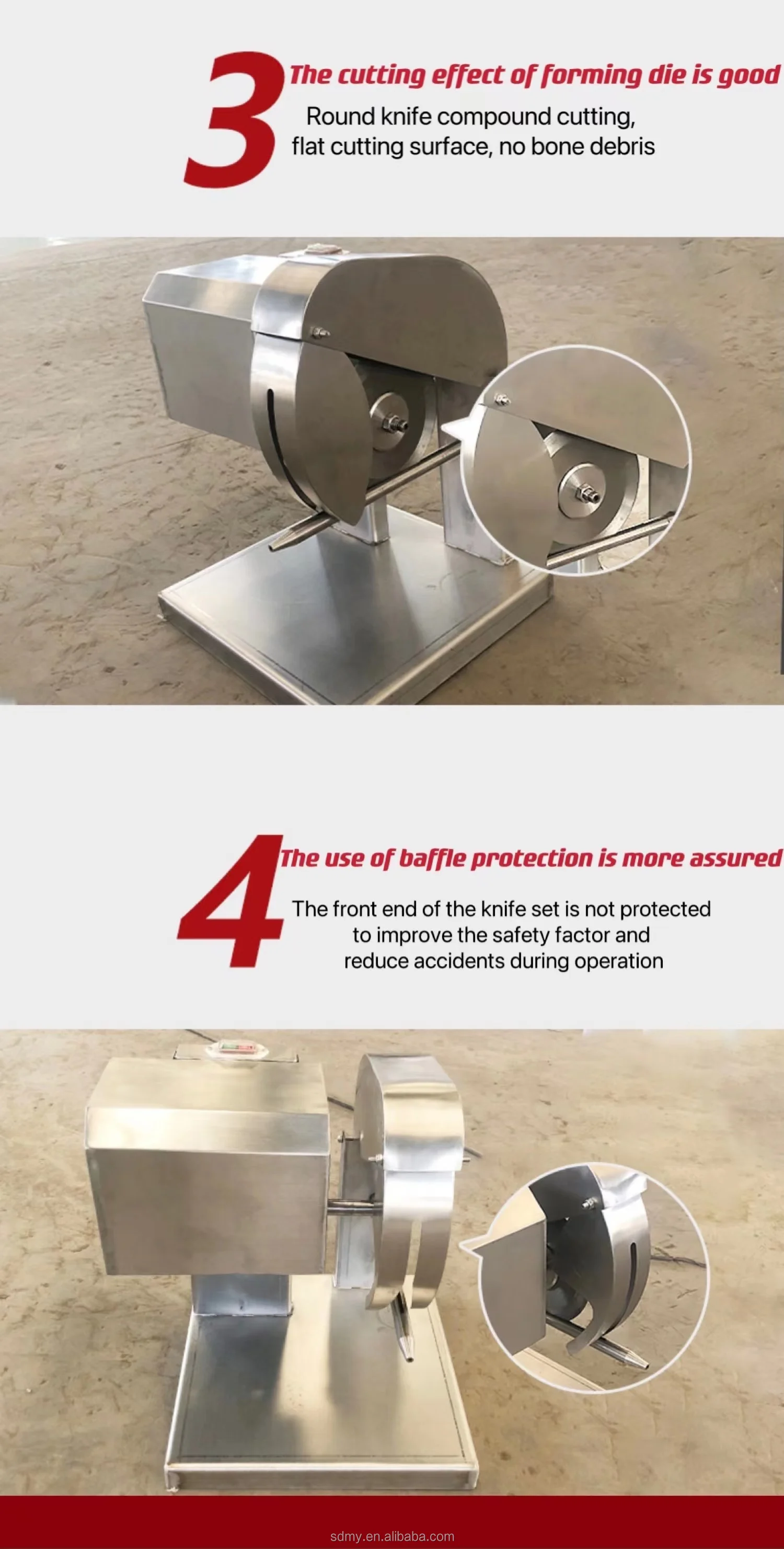

Q: What safety features should a vertical cutting machine have?

A: Key safety features include emergency stop buttons, protective guards, and automatic blade locking. These minimize operator risks during high-speed or heavy-duty cutting operations.

Q: Can a straightening and cutting wire machine handle different wire diameters?

A: Yes, most models are adjustable and support multiple wire diameters. Operators can configure settings like tension and cutting length to accommodate materials ranging from thin wires to thicker cables.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025