chicken scalders

Nov . 20, 2024 03:51 Back to list

chicken scalders

Understanding Chicken Scalders A Key Process in Poultry Processing

Chicken scalders are essential equipment in the poultry processing industry, playing a pivotal role in preparing chickens for further processing. This method involves submerging freshly plucked chickens in hot water, which serves several critical functions. Understanding the details of chicken scalders, their operation, and their importance can help us appreciate their role in delivering quality poultry products.

The Scalding Process

Scalding is the process of heating the carcass in water at specific temperatures to facilitate the removal of feathers. Typically, the temperature ranges between 140°F to 160°F (60°C to 71°C), depending on the type of processing plant and the poultry species. The primary objective is to loosen the feathers, allowing for easier plucking. Without effective scalding, feather removal can be inefficient, leading to a lower quality product and increased processing time.

The scalding process is crucial not only for feather removal but also plays a role in maintaining the meat quality. When chickens are processed, the scalding helps to loosen the skin and tissues, which can enhance the overall texture and appearance of the meat. Properly scalded chickens are more visually appealing and can be sold at a higher price point, making this process economically significant for producers.

Types of Scalders

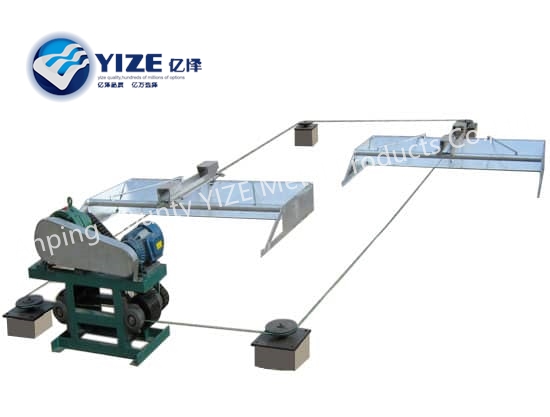

There are several types of chicken scalders used in the poultry industry. The most common ones include batch scalders and continuous scalders. Batch scalders allow for the immersion of multiple chickens at once and can be manually operated, which is often seen in smaller operations. Continuous scalders, on the other hand, are more prevalent in large-scale production facilities. They operate on an assembly line model, where chickens are continuously fed into the scalding chamber for a set period.

chicken scalders

In addition, some modern scalders incorporate advanced features such as temperature control systems, water circulation, and filtration. These innovations ensure that the scalding water remains at the optimal temperature and quality, further enhancing effectiveness and efficiency in the processing line.

Challenges and Considerations

While chicken scalders play a critical role in poultry processing, there are several challenges associated with their use. One significant concern is the management of water quality. Over time, the scalding water can become contaminated with organic matter, which can negatively impact the quality of the meat and potentially pose food safety risks. Regular monitoring and maintenance of the water quality are therefore essential in ensuring a safe and high-quality product.

Moreover, achieving the right scalding temperature is crucial; too high a temperature can cause issues such as skin damage or burning of the carcass, while too low temperatures could result in ineffective feather removal. This balance requires careful calibration and monitoring, and skilled operators must oversee the process to ensure optimal outcomes.

Conclusion

In conclusion, chicken scalders are a vital component in the poultry processing industry. They not only facilitate efficient feather removal but also help preserve the quality and appeal of the meat. As the industry continues to evolve, advancements in technology will likely improve the efficiency and effectiveness of scalding processes. By understanding the importance and functionality of chicken scalders, we can better appreciate the intricacies involved in bringing poultry products from farm to table, ensuring both quality and safety for consumers.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025