Efficient Poultry Scalding System for Enhanced Chicken Processing and Quality Control

Dec . 03, 2024 18:50 Back to list

Efficient Poultry Scalding System for Enhanced Chicken Processing and Quality Control

The Importance of Chicken Scalder Machines in Poultry Processing

The poultry industry is a cornerstone of the global food supply, providing millions of people with essential protein sources. One of the critical processes in chicken processing is plucking, which is effectively accomplished through the use of chicken scalder machines. These machines play an integral role in ensuring that chickens are prepared efficiently and hygienically for consumption.

What is a Chicken Scalder Machine?

A chicken scalder machine is specialized equipment used in the poultry processing industry to remove feathers from chickens after they have been slaughtered. The primary function of the scalder is to heat the birds in hot water; this loosens the feathers, making it easier to remove them during the plucking process. Scalder machines come in various designs, but they generally consist of a large water tank, heating elements, and a mechanism for controlling the temperature and timing of the scalding process.

How Does It Work?

The scalding process typically involves immersing the carcasses in hot water, usually between 140°F to 160°F (60°C to 71°C). The duration of scalding is crucial; too short a time in the water can result in insufficient feather loosening, while prolonged exposure can damage the skin and underlying tissues. Each scalding machine is equipped with precise temperature controls to ensure consistency and efficiency.

After scalding, the chickens are transferred to a plucking machine, where mechanical fingers or rubberized surfaces help to remove the loosened feathers. This method is not only faster than manual plucking but also significantly enhances hygiene by reducing the contact between workers and the carcasses.

Importance of Hygiene and Efficiency

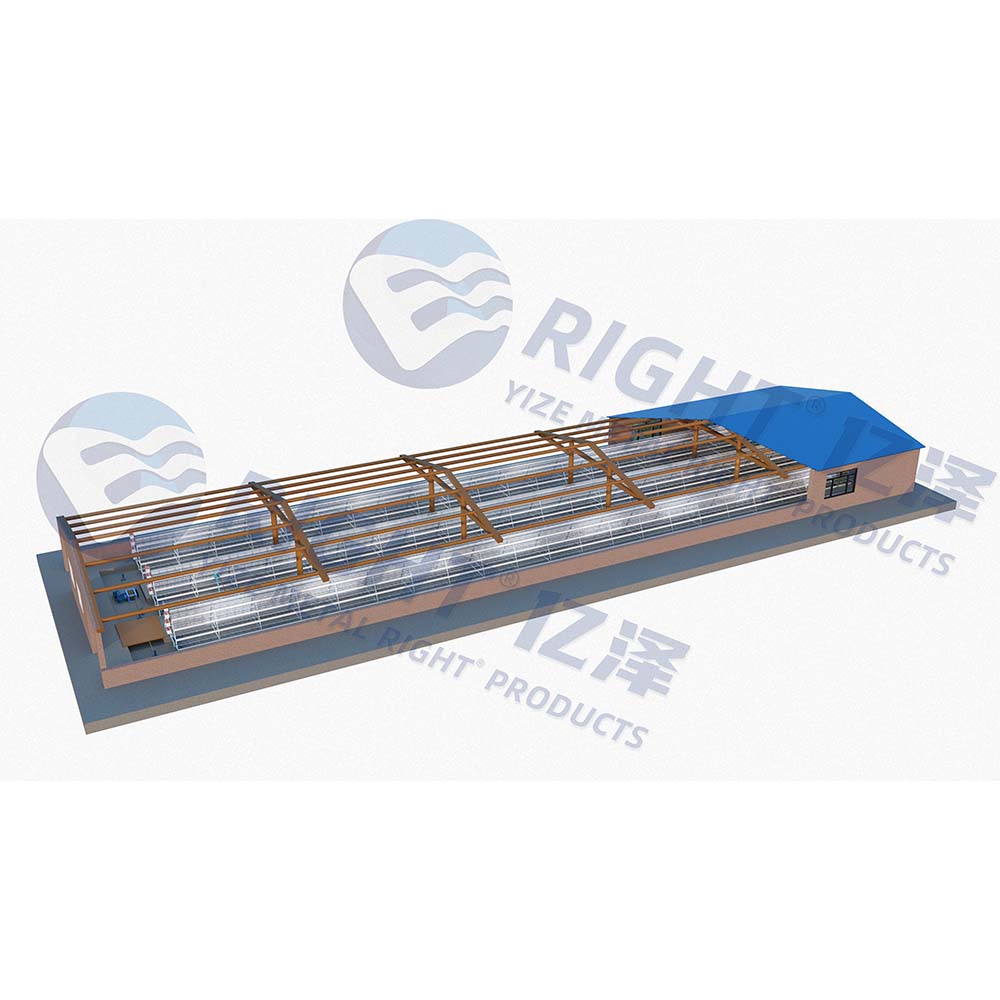

chicken scalder machine

In modern poultry processing, hygiene is paramount. Chicken scalder machines contribute significantly to food safety by ensuring that the scalding process is performed at the right temperatures, which also aids in reducing the microbial load on the surface of the chicken. Properly scalded birds present fewer risks of disease transmission, which is crucial for consumer safety and regulatory compliance.

Efficiency is another critical factor in poultry processing. As global demand for chicken continues to rise, processors are under pressure to increase their output without compromising quality. Scalder machines allow for higher throughput, enabling processing plants to handle larger volumes of chickens in shorter time frames. This efficiency contributes to the overall competitiveness of poultry producers in the market.

Technological Advancements

Recent technological advancements have significantly improved the design and functionality of chicken scalder machines. Many modern machines feature automated systems, which reduce the need for manual intervention during the scalding process. These advancements not only enhance efficiency but also allow for better monitoring of water quality and temperature, ensuring that the scalding process is consistent and meets industry standards.

Moreover, eco-friendly alternatives are emerging in the poultry processing industry. Some manufacturers are now designing scalder machines that use less water and energy, incorporating features like heat recovery systems to make the processes more sustainable. As environmental concerns grow, such innovations are essential for future-proofing poultry processing operations.

Conclusion

In conclusion, chicken scalder machines are vital to the success and efficiency of the poultry processing industry. They ensure that chickens are prepared hygienically and efficiently for consumers while playing a key role in meeting the increasing global demand for poultry products. With ongoing technological improvements and a focus on sustainability, the future of chicken scalder machines looks promising, driving both productivity and responsible practices in poultry processing. As consumers become more aware of food safety and environmental impacts, the role of scalder machines in producing high-quality, safe chicken will continue to grow in importance.

-

Automatic Feeding Line System Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker|Broiler Farming Equipment

NewsJul.29,2025

-

Automatic Feeding Line System - Anping Yize | Efficiency&Durability

NewsJul.29,2025

-

Automatic Feeding Line System - Anping Yize|Poultry Efficiency&Durability

NewsJul.29,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Durable PP Material&Easy Maintenance

NewsJul.29,2025