Effective Techniques for Chicken Scalder Usage and Maintenance in Poultry Processing

Dec . 18, 2024 13:43 Back to list

Effective Techniques for Chicken Scalder Usage and Maintenance in Poultry Processing

The Importance of Chicken Scalders in Poultry Processing

In the poultry processing industry, efficiency, hygiene, and poultry welfare are of utmost importance. One essential piece of equipment that significantly contributes to these factors is the chicken scalder. This machine plays a critical role in preparing chickens for plucking by removing feathers while ensuring that the birds are treated humanely.

What is a Chicken Scalder?

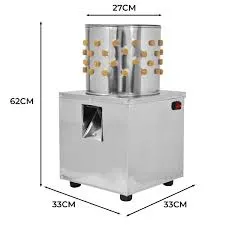

A chicken scalder is a large, typically stainless steel tank filled with hot water, designed to scald chickens after they have been slaughtered. The process of scalding involves immersing the birds in water heated to a specific temperature, which helps loosen and facilitate the removal of feathers. Scalding is vital because it enhances the efficiency of downstream processes, particularly feather removal, and helps maintain the quality and welfare of the birds.

How Does Scalding Work?

The scalding process typically occurs immediately after slaughter. After the chickens are dispatched, they are transferred to the scalder. The water temperature in the scalder is usually maintained between 140°F to 160°F (60°C to 71°C), depending on the specific type of chicken and the processing requirements. The duration of immersion varies but generally lasts from 30 seconds to several minutes, depending on the desired results.

The heat from the water helps to denature the proteins in the skin and feathers, making it easier for machines or workers to pluck the feathers afterward. Proper scalding is crucial; if the water is too hot or the duration too long, it can result in skin damage, which can compromise the quality of the meat. Conversely, if the water is not hot enough or the immersion time is too short, the feathers will be difficult to remove.

The Benefits of Using a Scalder

1. Improved Feather Removal The primary function of the scalder is to prepare chickens for feather plucking. Proper scalding ensures that feathers are loosened, allowing for more efficient removal, which significantly speeds up the processing time.

chicken scalder

2. Quality Control Effective scalding contributes to the overall quality of the poultry product. By ensuring that feathers are completely removed, processors can present a better product to consumers, paying off in customer satisfaction and repeat sales.

3. Hygienic Processing Scalding helps reduce microbial loads on the bird's skin. By applying high temperatures, it can eliminate some pathogens that may be present, improving the overall hygiene of the processed chickens.

4. Animal Welfare A properly designed scalder allows for a humane processing method. By reducing stress and ensuring a quick transition from live birds to processed products, scalder systems can support better animal welfare standards.

Innovations in Scalding Technology

With advancements in poultry processing technologies, chicken scalders have evolved significantly. Modern systems incorporate automated features, enhanced water circulation, and precise temperature controls. Some scalders utilize water recirculation systems, which not only conserve water but also maintain consistent temperatures and reduce energy consumption.

Additionally, there is an increasing focus on the environmental impact of poultry processing. Some manufacturers are developing scalders that minimize water and energy usage while still ensuring effective scalding.

Conclusion

In summary, chicken scalders are pivotal to the poultry processing industry. They facilitate efficient feather removal, enhance product quality, promote hygienic practices, and contribute to animal welfare. As technology continues to advance, the role of chicken scalders will likely evolve, becoming even more efficient and environmentally friendly. Understanding their function and importance is essential for anyone involved in poultry processing, from farm owners to industry processors and consumers concerned with food quality.

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025