Optimal Chicken Scalding Techniques for Effective Processing and Quality Improvement

Dec . 11, 2024 10:21 Back to list

Optimal Chicken Scalding Techniques for Effective Processing and Quality Improvement

Understanding the Chicken Scalder An Essential Step in Poultry Processing

The poultry industry is a vital sector of agriculture that plays a critical role in food production worldwide. Among the many processes involved in converting live chickens into the packaged products consumers find in grocery stores, a particularly crucial step is scalding. The chicken scalder is an indispensable piece of equipment in this process.

What is a Chicken Scalder?

A chicken scalder is a specialized machine designed to immerse chickens in hot water, which serves several purposes in poultry processing. Typically, the scalding process occurs after the chickens have been killed and before they are plucked. The primary goals of scalding are to loosen feathers, facilitate easier plucking, and ensure that the skin remains intact for aesthetic and hygienic reasons.

The Scalding Process

The scalding process generally involves heating water to a temperature between 130°F to 160°F (approximately 54°C to 71°C). The optimal temperature can vary depending on the type of chicken being processed and specific requirements of the processing plant. For instance, younger birds may require lower temperatures compared to older ones. The duration of exposure to hot water also plays a critical role, as it must be long enough to loosen the feathers but not so long that it alters the meat texture or leads to cooking the muscle tissues.

Once the chickens have been submerged in the scalding tank for the appropriate duration, they are then moved to the plucking machine, where mechanical fingers help remove the feathers, leading to a cleaner product ready for further processing.

Types of Chicken Scalders

chicken scalder

There are two primary types of chicken scalders batch and continuous.

1. Batch Scalders These are smaller, designed to process limited quantities of chickens at a time. They are often used in smaller or organic processing operations where the volume does not justify a continuous system. Batch scalders are versatile and can often adjust to varying temperatures depending on the requirements.

2. Continuous Scalders These are larger systems designed for high-volume processing plants. Continuous scalders allow for a steady flow of chickens through a hot water bath, which maintains a consistent temperature and optimizes efficiency. This system is crucial for large-scale operations that require quick processing times while maintaining quality.

Importance of the Scalder in Food Safety

Scalding is not only about feather removal; it also contributes to food safety. Proper scalding can help eliminate bacteria and other pathogens present on the chicken's skin. By effectively utilizing the scalder, processors can significantly reduce the risk of contamination throughout the supply chain.

Moreover, maintaining the right temperature and timing in the scalding process ensures the chicken remains safe for consumption. Improper scalding can lead to challenges such as feather residue, bruising, and even compromised meat quality, all of which can affect the wholesomeness of the final product.

Conclusion

In conclusion, the chicken scalder is a vital component in the poultry processing industry that not only aids in the efficient removal of feathers but also plays a significant role in ensuring food safety. Understanding its functions, types, and importance can help anyone interested in the poultry industry appreciate the complexities involved in producing the chicken products that many consumers enjoy. As the demand for poultry continues to grow, optimizing scalding techniques and technologies will be essential for maintaining high standards of quality and safety.

-

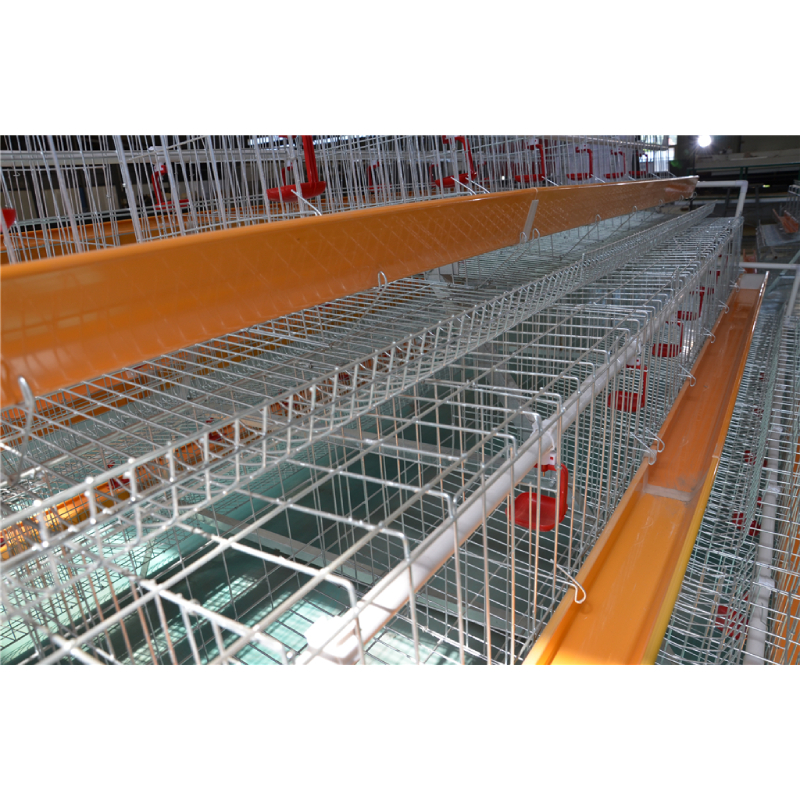

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025