chicken plucker and scalder

Feb . 11, 2025 21:56 Back to list

chicken plucker and scalder

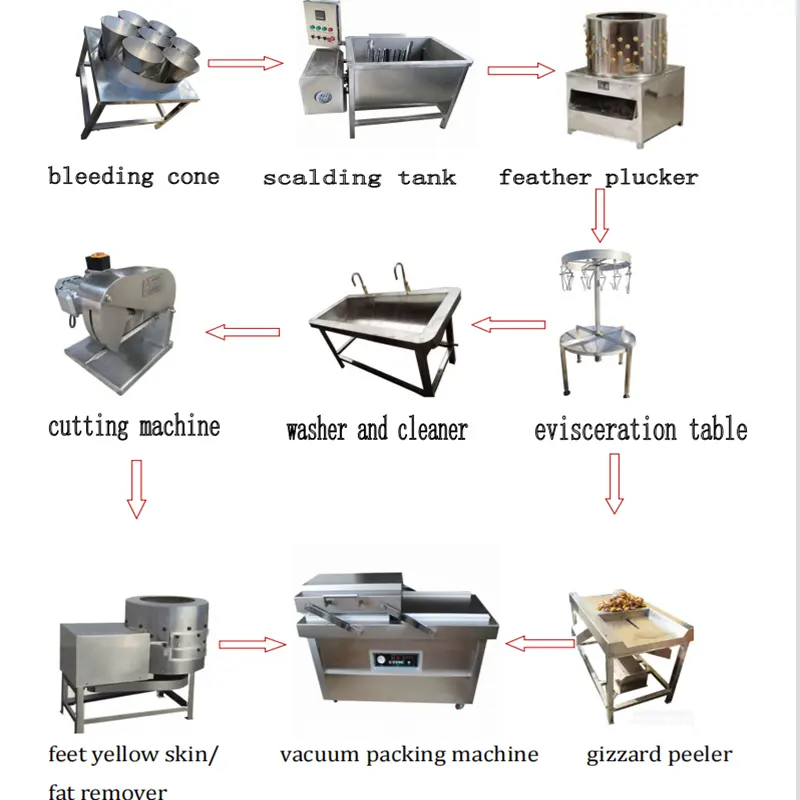

In the realm of poultry processing, the tools you choose can dramatically impact the efficiency and quality of your operation. Among these tools, the chicken plucker and scalder hold a significant position, catering to both small-scale backyard enthusiasts and large commercial farms. Experience with these tools can elevate the processing cycle, ensuring maximum yield and product quality.

Professional advice underscores the importance of equipment maintenance to sustain peak performance. Regular cleaning of the plucker, for example, prevents residue build-up that can impact functionality. Seasoned users recommend inspecting the rubber fingers regularly for any sign of wear and replacing them as needed to ensure efficiency. Similarly, the scalder should be descaled periodically to prevent mineral build-up, which can affect heating efficiency. In enhancing the authoritativeness of your poultry processing setup, consider integrating automated systems. Utilizing automatic water refill systems with the scalder maintains consistent water levels and temperatures, reducing manual oversight. Paired with automated timers on the plucker, these systems offer an optimized workflow, freeing up time for operators to focus on other critical areas of production. One's expertise with chicken plucker and scalder is not merely limited to the machines themselves, but extends to the entire processing workflow. Experts recommend creating a seamless processing line that includes chilling areas post-plucking and scalding for preserving meat quality. Proper bleeding, scalding, plucking, and chilling not only improve the meat's texture and appearance but also enhance shelf life. Building your operation's authority relies on credibility and consistent results. Trust is earned through delivering high-quality, efficiently processed poultry, whether you supply local markets or larger commercial distributors. By mastering the use of a chicken plucker and scalder, and investing in robust, reliable equipment, you set the foundation for a reputable and successful poultry processing enterprise. In conclusion, the strategic use of chicken plucker and scalder not only boosts productivity but also enhances product quality, resonating with the Experience, Expertise, Authoritativeness, and Trustworthiness that define a successful operation. By focusing on these attributes, poultry processors can achieve superior outcomes, cementing their position in the ever-competitive market.

Professional advice underscores the importance of equipment maintenance to sustain peak performance. Regular cleaning of the plucker, for example, prevents residue build-up that can impact functionality. Seasoned users recommend inspecting the rubber fingers regularly for any sign of wear and replacing them as needed to ensure efficiency. Similarly, the scalder should be descaled periodically to prevent mineral build-up, which can affect heating efficiency. In enhancing the authoritativeness of your poultry processing setup, consider integrating automated systems. Utilizing automatic water refill systems with the scalder maintains consistent water levels and temperatures, reducing manual oversight. Paired with automated timers on the plucker, these systems offer an optimized workflow, freeing up time for operators to focus on other critical areas of production. One's expertise with chicken plucker and scalder is not merely limited to the machines themselves, but extends to the entire processing workflow. Experts recommend creating a seamless processing line that includes chilling areas post-plucking and scalding for preserving meat quality. Proper bleeding, scalding, plucking, and chilling not only improve the meat's texture and appearance but also enhance shelf life. Building your operation's authority relies on credibility and consistent results. Trust is earned through delivering high-quality, efficiently processed poultry, whether you supply local markets or larger commercial distributors. By mastering the use of a chicken plucker and scalder, and investing in robust, reliable equipment, you set the foundation for a reputable and successful poultry processing enterprise. In conclusion, the strategic use of chicken plucker and scalder not only boosts productivity but also enhances product quality, resonating with the Experience, Expertise, Authoritativeness, and Trustworthiness that define a successful operation. By focusing on these attributes, poultry processors can achieve superior outcomes, cementing their position in the ever-competitive market.

Latest news

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025