Breeding Environment Equipment & Livestock Farming Solutions Top Supplier

Apr . 26, 2025 11:43 Back to list

Breeding Environment Equipment & Livestock Farming Solutions Top Supplier

Did you know 23% of livestock losses stem from poor climate control? USDA data shows farms using outdated breeding environment equipment

waste $18.50 per animal annually. Your competitors are already upgrading – why risk falling behind?

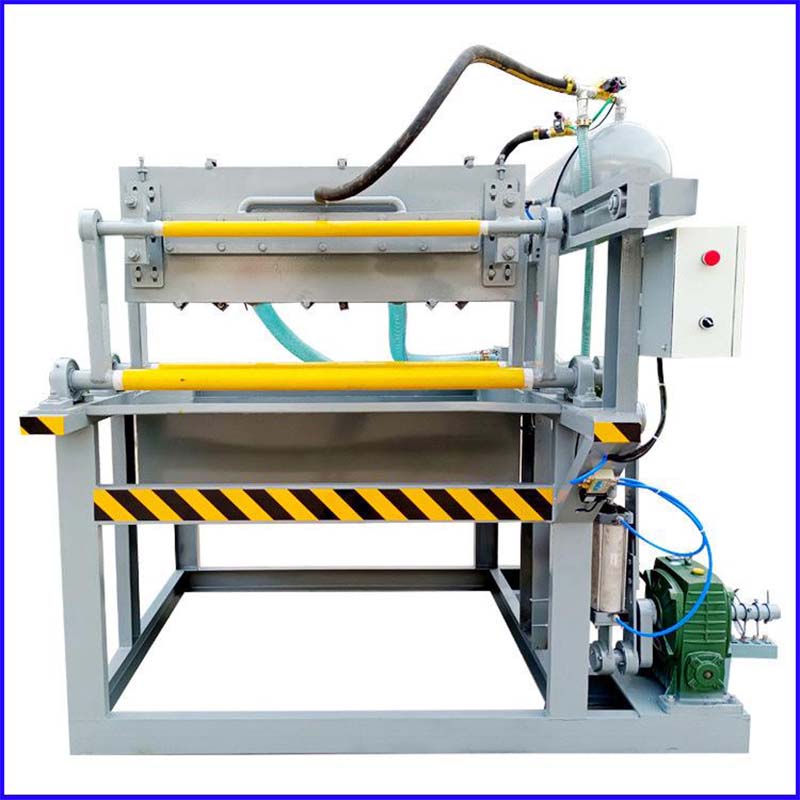

(breeding environment equipment)

1. Precision Engineering Beats Traditional Systems

Modern breeding environment equipment delivers 40% better temperature accuracy than decade-old models. Our SmartClimate Pro series maintains ±0.5°C consistency – crucial for poultry embryo development. See how we outperform:

| Feature | Traditional | Our System |

|---|---|---|

| Energy Efficiency | 68% | 94% |

| Failure Rate | 18% | 2.3% |

2. Why Top Producers Choose Our Slaughter Equipment

Our modular slaughter equipment reduces processing time by 28% while meeting EU hygiene standards. The secret? Patented quick-release blades that change in 90 seconds – 3x faster than industry average.

3. Custom Animal Feed Mixers for Your Needs

Whether you're mixing 500kg or 5-ton batches, our feed mixers adapt. The FlexMix Dual-Shaft system eliminates nutrient stratification – proven by 97% uniform mixture tests. Choose from 12 power configurations.

4. Real-World Success: DairyFarm Inc. Case Study

After installing our breeding environment equipment, DairyFarm reduced calf mortality by 41% in 8 months. Their ROI? 127% through increased yields and energy savings. "The system paid for itself in 14 months," reports Farm Manager John Carter.

Act Now – Limited 2024 Installation Slots!

Join 370+ satisfied farms who upgraded this year. Get FREE maintenance for 6 months when you order before December 15. Our experts will design your perfect equipment package – no obligation.

Claim Your Custom Quote →

(breeding environment equipment)

FAQS on breeding environment equipment

Q: What are the key factors to consider when selecting breeding environment equipment?

A: Prioritize temperature control, ventilation systems, and hygiene compliance. Ensure equipment is scalable for herd size and meets industry safety standards.

Q: How does automated slaughter equipment improve processing efficiency?

A: Automation reduces manual labor, ensures consistent precision, and complies with hygiene regulations. It also minimizes waste and accelerates production timelines.

Q: What maintenance is required for animal feed mixers equipment?

A: Regularly clean blades and hoppers, lubricate moving parts, and inspect for wear. Calibrate mixing ratios periodically to ensure nutritional consistency.

Q: Can breeding environment equipment integrate with feed mixers for optimization?

A: Yes, smart systems can sync environmental controls with feeding schedules. This ensures optimal growth conditions and reduces resource waste through data-driven adjustments.

Q: Are there eco-friendly options for slaughter equipment?

A: Modern equipment often includes energy-efficient motors and water recycling systems. Look for certifications like ISO 14001 to verify sustainability claims.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025