Efficient Automated Feeding System for Streamlined Production Processes

Oct . 11, 2024 19:05 Back to list

Efficient Automated Feeding System for Streamlined Production Processes

The Evolution and Benefits of Automatic Feeding Lines in Modern Industry

In the ever-evolving landscape of industrial manufacturing, the pursuit of efficiency and precision has led to the adoption of numerous advanced technologies. One particularly significant advancement is the use of automatic feeding lines. This innovation has transformed production processes across various sectors, from automotive to food processing, enhancing productivity while minimizing labor costs and errors.

Automatic feeding lines are systems designed to transport and feed various materials or components into machines or assembly lines without the need for manual intervention. These systems utilize a combination of conveyor belts, robotics, and sensors to ensure that workpieces are delivered precisely where they are needed, often with remarkable speed and consistency.

One of the primary benefits of automatic feeding lines is increased efficiency. In traditional manufacturing, workers would manually feed materials into machines, a process that is not only time-consuming but also prone to human error. By automating this task, companies can streamline their operations significantly. For instance, in the automotive industry, automatic feeding lines can deliver parts like screws, bolts, and other components to assembly stations in a seamless flow, reducing downtime and accelerating production rates. This increase in efficiency often translates to higher output and better utilization of resources, contributing to overall profitability.

Moreover, automatic feeding lines contribute to improved workspace safety. In environments where heavy machinery and hazardous materials are involved, having fewer workers on the floor reduces the risk of accidents. Automatic systems can handle the repetitive and often dangerous task of material handling. For example, in the food processing industry, automatic feeders are used to transport ingredients to processing machines without exposing workers to potential hazards. This aspect not only protects employees but also ensures compliance with stringent safety regulations, ultimately fostering a safer working environment.

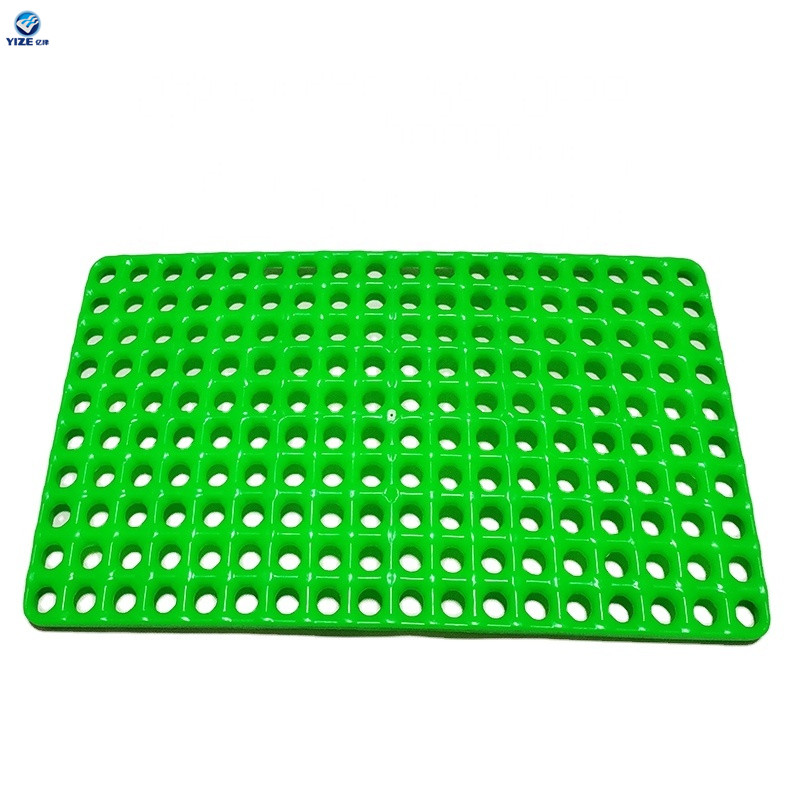

automatic feeding line

Additionally, the precision offered by automatic feeding lines is invaluable. In industries such as electronics manufacturing, where tiny components must be handled with the utmost care, precision feeding systems are essential. Automatic feeders can accurately position components in machines, ensuring that each piece is placed correctly. This level of accuracy minimizes defects and waste, ensuring that products meet quality standards. As consumers become increasingly discerning, maintaining high quality is paramount for companies seeking to maintain a competitive edge.

The integration of smart technology further enhances the capabilities of automatic feeding lines. With advancements in artificial intelligence and the Internet of Things (IoT), these systems can be monitored and controlled remotely. Operators can track performance metrics, diagnose issues, and optimize workflows in real-time. For instance, if a machine encounters an error, the feeding line can automatically halt, preventing further issues and allowing for quick intervention. This capability not only boosts operational efficiency but also minimizes costly downtime.

Furthermore, the adaptability of automatic feeding lines makes them suitable for various applications. Companies can customize these systems to accommodate different materials, shapes, and sizes based on their specific production needs. This flexibility is particularly advantageous for businesses that regularly introduce new products or variations in design. The automated systems can be reprogrammed or reconfigured with minimal disruption, allowing for agile manufacturing practices that respond to changing market demands.

In conclusion, the implementation of automatic feeding lines has ushered in a new era of efficiency, safety, and precision in manufacturing. As industries continue to evolve and embrace automation, these systems will play an increasingly vital role in streamlining production processes. By reducing labor costs, enhancing product quality, and improving workplace safety, automatic feeding lines represent a significant investment toward a more productive and sustainable industrial future. As technology continues to advance, the potential for these systems to innovate further and adapt to new challenges will be limitless, providing companies with the tools they need to thrive in an ever-competitive market.

-

Automatic Feeding Line System - Anping Yize|Poultry Efficiency&Durability

NewsJul.29,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Durable PP Material&Easy Maintenance

NewsJul.29,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025