automatic chicken layer cage

Feb . 19, 2025 06:54 Back to list

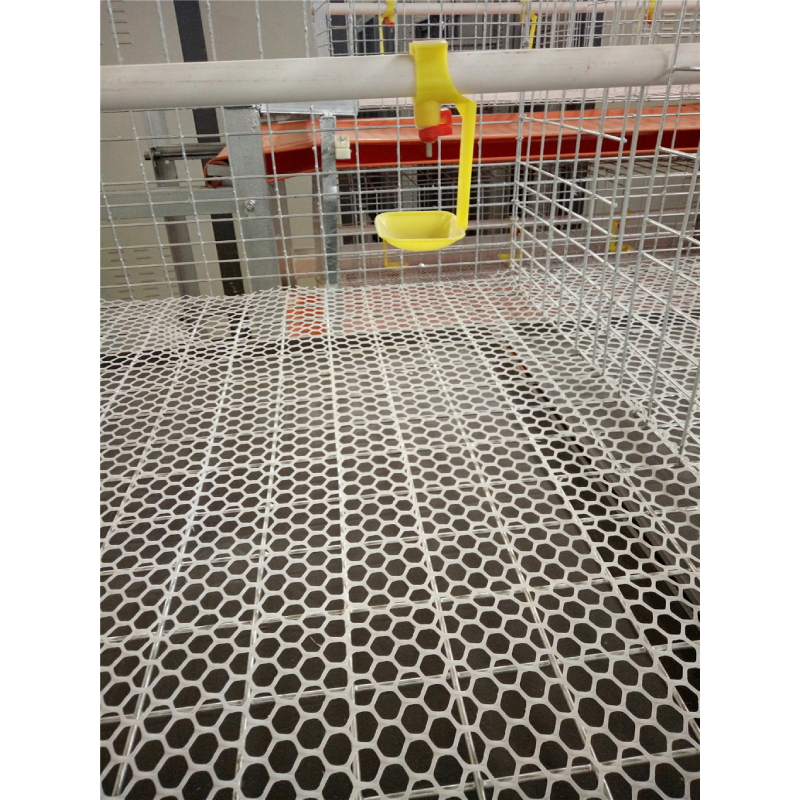

automatic chicken layer cage

Automatic chicken layer cages represent a revolutionary advancement in poultry farming, integrating technology and practicality to enhance productivity and efficiency. These cages not only streamline the management of layers but also contribute significantly to the welfare and output of the poultry sector.

From an environmental perspective, automatic chicken layer cages contribute positively by enabling better waste management. These cages often include manure belts designed to efficiently collect and dispose of waste, reducing odor and minimizing the risk of disease. The ability to manage waste effectively not only contributes to healthier living conditions for the poultry but also aligns with sustainable farming practices by reducing environmental impact. The initial investment in automatic chicken layer cages may seem substantial, yet the long-term benefits and cost savings frequently outweigh the upfront costs. The reduction in labor, increase in production efficiency, and improvement in egg quality can lead to higher profit margins. Farms utilizing these systems often report a noticeable improvement in productivity and product quality, reinforcing the economic viability of the investment. However, transitioning to automatic systems requires an understanding of modern farming technologies and a willingness to adapt to new operational methods. Training and support from the manufacturers can bridge this knowledge gap, ensuring that farmers not only implement the systems effectively but also make full use of the functionalities available. As these systems gain popularity globally, many manufacturers provide robust after-sales support and maintenance services. This ensures that the systems operate smoothly with minimal downtime, thus maintaining continuous productivity. By partnering with reputable suppliers, farmers can ensure reliable service and quality assurance, further cementing trust and authority within the agricultural community. In summary, automatic chicken layer cages stand as a testament to the advancements in agricultural technology, combining efficiency, productivity, and environmental care. By embracing such innovations, farmers are not only better positioned to meet the growing demands of the poultry market but also contribute to the sustainability and modernization of farming practices worldwide.

From an environmental perspective, automatic chicken layer cages contribute positively by enabling better waste management. These cages often include manure belts designed to efficiently collect and dispose of waste, reducing odor and minimizing the risk of disease. The ability to manage waste effectively not only contributes to healthier living conditions for the poultry but also aligns with sustainable farming practices by reducing environmental impact. The initial investment in automatic chicken layer cages may seem substantial, yet the long-term benefits and cost savings frequently outweigh the upfront costs. The reduction in labor, increase in production efficiency, and improvement in egg quality can lead to higher profit margins. Farms utilizing these systems often report a noticeable improvement in productivity and product quality, reinforcing the economic viability of the investment. However, transitioning to automatic systems requires an understanding of modern farming technologies and a willingness to adapt to new operational methods. Training and support from the manufacturers can bridge this knowledge gap, ensuring that farmers not only implement the systems effectively but also make full use of the functionalities available. As these systems gain popularity globally, many manufacturers provide robust after-sales support and maintenance services. This ensures that the systems operate smoothly with minimal downtime, thus maintaining continuous productivity. By partnering with reputable suppliers, farmers can ensure reliable service and quality assurance, further cementing trust and authority within the agricultural community. In summary, automatic chicken layer cages stand as a testament to the advancements in agricultural technology, combining efficiency, productivity, and environmental care. By embracing such innovations, farmers are not only better positioned to meet the growing demands of the poultry market but also contribute to the sustainability and modernization of farming practices worldwide.

Next:

Latest news

-

Automatic Feeding Line System Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.30,2025

-

Automatic Feeding Line System - Anping Yize|Pan Feeder,Nipple Drinker

NewsJul.30,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Pan Feeder, Nipple Drinker

NewsJul.30,2025

-

Automatic Feeding Line System-Poultry Farming|Chicken Feeding&Watering

NewsJul.30,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Pan Feeder Nipple Drinker,Broiler Farming

NewsJul.30,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker-Anping County Yize Metal Products Co., Ltd.

NewsJul.30,2025