Automatic Drinking Line | Leak-Proof, Hygienic, Fast Setup

Oct . 27, 2025 12:25 Back to list

Automatic Drinking Line | Leak-Proof, Hygienic, Fast Setup

automatic drinking line, automatic feeding line, breeding environment equipment is a key solution in the animal husbandry industry, specifically within Livestock machinery and equipment and Automated feeding and drinking water equipment. This article explores how Anping County Yize Metal Products Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- automatic drinking line, automatic feeding line, breeding environment equipment Overview

- Benefits & Use Cases of automatic drinking line, automatic feeding line, breeding environment equipment in Automated feeding and drinking water equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in animal husbandry

- Conclusion on automatic drinking line, automatic feeding line, breeding environment equipment from Anping County Yize Metal Products Co., Ltd.

automatic drinking line, automatic feeding line, breeding environment equipment Overview

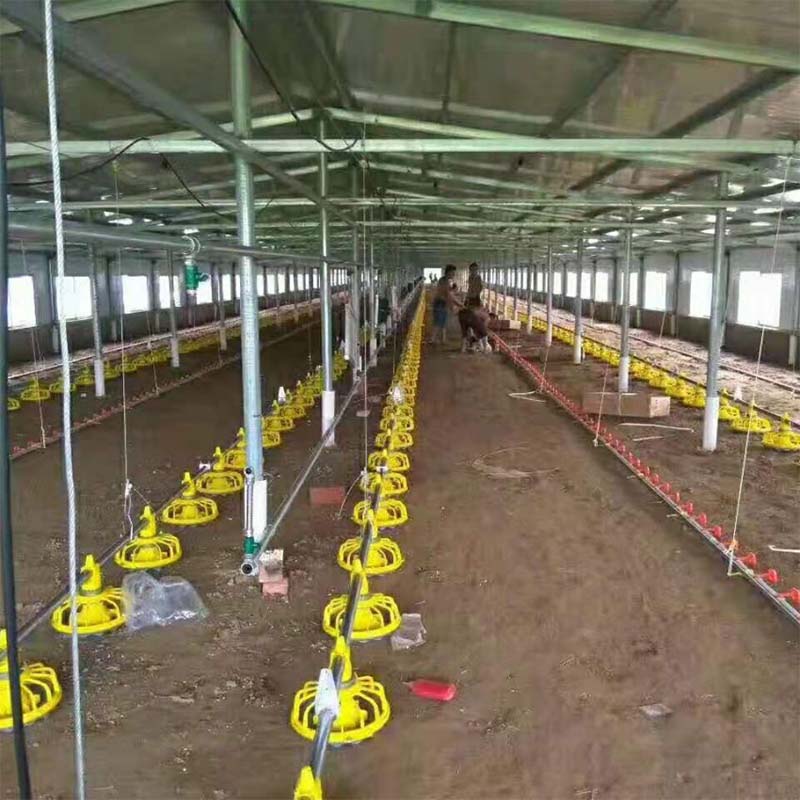

In modern poultry and livestock operations, the automatic feeding line and automatic drinking line form the backbone of consistent growth performance, biosecurity, and labor efficiency. Typically built around a centralized hopper, drive motor, spiral auger, and modular feed pans, the feeding line delivers precise rations with minimal spillage. The drinking line—with pressure regulators, filters, medicators, and 360° nipple drinkers—ensures clean, reliable water access that reduces disease risk. Complementary breeding environment equipment (ventilation, climate control, and lighting) stabilizes house conditions, translating to better feed conversion and uniformity.

Anping County Yize Metal Products Co., Ltd. manufactures robust systems designed for high-duty cycles and corrosive barn environments. Materials commonly used include hot-dip galvanized steel, food-grade plastics, and stainless-steel components in key wear points. Optional sensors can automate feed level, while quick-release pans and flushable drinker lines simplify sanitation between flocks. For example, in retrofit houses, integrators often report improved feed distribution uniformity once line height, pan flood settings, and drinker pressure are calibrated correctly. The result is a repeatable, data-driven feeding and watering process aligned with the demands of modern animal husbandry.

Benefits & Use Cases of automatic drinking line, automatic feeding line, breeding environment equipment in Automated feeding and drinking water equipment

Across broiler, breeder, and layer operations—as well as specialty poultry like ducks and turkeys—automatic systems improve consistency, reduce labor, and enhance welfare. The automatic feeding line’s modular sections and adjustable pan grills allow tailored access by bird age and type. Coupled with a reliable automatic drinking line, farmers maintain steady intake and reduce contamination risk versus open troughs. Breeding environment equipment (ventilation, evaporative cooling, heaters, sensors, and controllers) completes the system, maintaining optimal temperature, humidity, and air quality to protect respiratory health and feed conversion.

Key advantages include:

- Precision: Stable feed flow and consistent water pressure, supported by feed-level sensors and pressure regulators.

- Hygiene: Enclosed water delivery and anti-waste pan design help cut contamination and litter moisture.

- Flexibility: Easy height adjustment and pan flood settings for brooding through grow-out stages.

- Serviceability: Quick-disassembly pans, flushable drinker lines, and standardized spare parts.

Anping County Yize Metal Products Co., Ltd. brings sector expertise with systems engineered for long service life, straightforward installation, and compatibility with common house layouts and controllers. Whether for new builds or retrofits, the company’s automated feeding and drinking water equipment helps B2B decision makers balance performance, cost, and compliance.

Cost, Maintenance & User Experience

Total cost of ownership (TCO) in automated feeding and drinking systems depends on durability, ease of cleaning, energy consumption, and downtime. Yize designs its automatic feeding line with low-power motors and wear-resistant augers to keep energy and maintenance demands in check. The automatic drinking line’s durable nipples and regulators are selected for stable flow and long life, reducing replacement intervals. For many producers, labor efficiency—fewer hours spent on hand-feeding, water checks, and line adjustments—becomes the biggest contributor to ROI.

Recommended maintenance routines include daily line-height checks, weekly drinker flushing and filter inspection, and scheduled auger and motor inspections between flocks. Users value quick-lock pans for rapid cleaning and standardized parts that simplify spares management. Feedback from the Livestock machinery and equipment sector often highlights measurable reductions in feed spillage and improvements in bird uniformity once lines are properly calibrated. Over multiple flocks, the combined effect is fewer mortalities from dehydration or over-wetting, steadier growth curves, and smoother harvest planning—all key levers for payback.

Sustainability & Market Trends in animal husbandry

Regulatory and market pressures increasingly favor precision, welfare-forward systems that reduce waste and environmental load. Closed-nipple automatic drinking lines minimize water loss, helping maintain drier litter and lowering ammonia formation. Efficient automatic feeding lines curb fines and spillage, translating into reduced feed wastage—the largest variable cost in poultry production. Breeding environment equipment further supports sustainability by optimizing ventilation, temperature, and humidity; this leads to better bird comfort and lower energy use when paired with modern controls.

Market trends point to deeper digital integration—sensor-driven controllers, remote alerts, and data logging to optimize feed conversion and water use. Anping County Yize Metal Products Co., Ltd. takes a forward-looking approach by engineering equipment for compatibility with common controllers and emphasizing materials and coatings that extend service life and recyclability. For B2B buyers planning capital upgrades, this future-proofing—together with robust after-sales support—helps ensure compliance with evolving welfare standards and environmental targets while safeguarding production efficiency.

Conclusion on automatic drinking line, automatic feeding line, breeding environment equipment from Anping County Yize Metal Products Co., Ltd.

From consistent feed delivery to hygienic, regulated water access and stable in-house conditions, Yize’s automatic feeding line, automatic drinking line, and breeding environment equipment provide a dependable foundation for high-performance flocks. Built for durability and easy service, these solutions address today’s cost, labor, and compliance pressures while preparing operations for tomorrow’s data-driven management.

Contact us: email: sales@yizemetal.com

Visit our website: https://www.yizemachine.com

-

Evisceration Table - Hygienic, Stainless Steel, Easy-Clean

NewsNov.17,2025

-

Chicken Plucker and Scalder | Fast, Stainless, Adjustable

NewsNov.17,2025

-

Silo Solutions: Durable, Automated, Batching-Ready Storage

NewsNov.17,2025

-

Automatic Drinking Line for Poultry | Precise & Durable

NewsNov.17,2025

-

Cutting Machine for Meat & Bone | High-Precision, Safe

NewsNov.17,2025

-

Chicken Feet Peeling Machine | Fast, Hygienic, High-Yield

NewsNov.10,2025