Automated Drinking Line: Efficient & Hygienic Farm Solutions

Sep . 11, 2025 08:00 Back to list

Automated Drinking Line: Efficient & Hygienic Farm Solutions

The Evolution of Livestock Hydration: Understanding Advanced Automatic Drinking Line Systems

In modern animal husbandry, efficiency, hygiene, and animal welfare are paramount. Central to achieving these objectives is the implementation of advanced hydration solutions. A prime example is the automatic drinking line , a sophisticated system engineered to provide a constant, clean, and controlled water supply to livestock. These systems are indispensable for maximizing productivity, minimizing labor, and maintaining optimal animal health across various farming operations. Integrating seamlessly with components like the automatic feeding line and comprehensive breeding environment equipment, an automatic drinking line forms the backbone of a high-performance, sustainable livestock facility.

Industry Trends: Driving Innovation in Livestock Automation

The livestock industry is undergoing a significant transformation, driven by increasing global demand for animal protein, stringent welfare regulations, and the need for greater sustainability. Key trends shaping this evolution include:

- Precision Livestock Farming (PLF): Utilizing sensors, IoT devices, and data analytics to monitor individual animal health, growth, and environmental conditions in real-time. Automated drinking systems contribute critical hydration data to PLF platforms.

- Enhanced Biosecurity: Closed, automated systems significantly reduce human-animal contact, minimizing disease transmission risks. This is particularly vital for poultry and swine operations.

- Resource Efficiency: Innovations focusing on reducing water waste, energy consumption, and feed conversion ratios are becoming standard. Modern automatic drinking line systems are designed for optimal water conservation.

- Labor Optimization: Automation addresses labor shortages and reduces the physical burden on farm staff, allowing them to focus on animal welfare and system management.

- Sustainability & Environmental Stewardship: Farms are adopting practices and technologies that minimize their environmental footprint, including efficient waste management and responsible resource use.

Modern automatic drinking lines integrate seamlessly into smart farm infrastructure.

Manufacturing Process of Automatic Drinking Line Systems

The production of a robust and reliable automatic drinking line involves a series of meticulously engineered steps, ensuring durability, hygiene, and optimal performance in demanding farm environments.

Process Flow:

-

Material Selection & Sourcing:

- Piping: High-grade PVC (Polyvinyl Chloride) or polypropylene (PP) for water lines, chosen for its corrosion resistance, non-toxicity, and smooth interior surface to prevent biofilm buildup. UV stabilized for longevity in exposed environments.

- Nipple Drinkers: Precision-machined stainless steel (e.g., SUS304 or SUS316) for the nipple mechanisms, ensuring durability, wear resistance, and hygienic water delivery. Housing often uses engineering plastics like ABS or POM.

- Regulators & Filters: Durable plastics, brass, or stainless steel for pressure regulators, filters, and water meters, designed to withstand farm conditions and water treatment chemicals.

- Supports & Hangers: Galvanized steel or stainless steel for structural components, offering superior corrosion resistance and load-bearing capacity.

-

Component Manufacturing & Fabrication:

- Pipe Extrusion: PVC or PP pipes are extruded to precise diameters and wall thicknesses, ensuring consistent flow and pressure integrity.

- Nipple Machining: Stainless steel components for nipple drinkers undergo CNC machining to achieve extremely tight tolerances, critical for leak-free operation and consistent water release.

- Injection Molding: Plastic housings for nipples, drip cups, and other fittings are produced via injection molding, allowing for complex geometries and high volume with excellent repeatability.

- Metal Stamping/Forming: Brackets, hangers, and other support elements are formed from galvanized or stainless steel sheets.

-

Assembly & Integration:

- Individual components are assembled into complete drinking line sections, including the integration of nipples, drip cups, and flushing valves.

- Pressure regulators, filters, and medication dispensers are integrated at the system head.

-

Quality Control & Testing:

- Material Testing: Raw materials are tested to ensure compliance with relevant standards for food-grade contact and durability.

- Leakage Testing: Each drinking line segment undergoes rigorous pressure testing to detect any leaks and ensure hermetic sealing.

- Flow Rate Calibration: Nipple drinkers are tested for consistent water release rates, crucial for uniform hydration across the flock/herd.

- Performance Standards: Systems are tested against internal benchmarks and often adhere to international standards such as ISO 9001 for manufacturing quality.

Service Life & Target Industries:

A well-maintained automatic drinking line system, constructed with high-quality materials and manufacturing processes, typically offers a service life of 10-15 years or more. These systems are predominantly utilized in:

- Poultry Farming: Broilers, layers, breeders, and pullets.

- Swine Farming: Gestation, farrowing, nursery, and finishing pigs.

- Other Livestock: Rabbits, small ruminants, and specialized animal production.

Advantages in Application:

- Energy Saving: Efficient water delivery minimizes pump run times and reduces the energy associated with water treatment and distribution.

- Corrosion Resistance: Strategic use of PVC, PP, and stainless steel ensures long-term resistance to water, cleaning agents, and animal waste.

- Disease Prevention: Closed systems prevent water contamination from litter or droppings, significantly improving biosecurity and reducing pathogen spread.

- Optimized Hydration: Consistent availability of fresh water leads to better feed conversion rates and overall animal performance.

Precision engineering ensures the longevity and hygiene of drinking system components.

Technical Specifications and Components

An effective automatic drinking line system is comprised of several key components, each engineered for specific functions to ensure reliable and efficient water delivery.

Key Components:

- Nipple Drinkers: The core of the system, providing on-demand water. Available in various flow rates and trigger sensitivities for different animal types and ages (e.g., high flow for adult pigs, low flow for day-old chicks).

- Drip Cups (for poultry): Collect excess water, preventing wet litter and maintaining cage/floor hygiene.

- Pressure Regulator: Essential for maintaining consistent water pressure throughout the line, ensuring uniform water availability and preventing leaks or overflows.

- Water Filter: Removes impurities and sediment from the water source, protecting nipple drinkers from clogging and ensuring clean water.

- Flushing System: Allows for easy and rapid flushing of the drinking lines, removing biofilm, mineral buildup, and medication residues to maintain water quality.

- Main & Branch Water Lines: Constructed from durable PVC or galvanized pipe, designed for optimal flow and structural integrity.

- Medication Doser/Proportioner: Accurately injects soluble medications or supplements into the water line.

- Hanging & Lifting System: Allows adjustment of drinking line height to accommodate different animal ages and growth stages.

Typical Product Specifications for Poultry Nipple Drinking Line:

| Parameter | Specification |

|---|---|

| Pipe Material | High-grade PVC or PP, UV-stabilized |

| Nipple Drinker Material (Internal) | SUS304/SUS316 Stainless Steel |

| Nipple Drinker Material (Housing) | ABS/POM Engineering Plastic |

| Number of Nipples per 3m Pipe | Typically 10-12 (adjustable per animal density) |

| Optimal Operating Pressure | 20-40 cm H₂O (0.2-0.4 bar) |

| Nipple Flow Rate (Poultry) | 30-80 ml/min (depending on model) |

| System Capacity (per line) | Up to 60-75 meters (dependent on pressure stability) |

| Installation Type | Suspended, height-adjustable via winch system |

| Water Filtration | Standard 10-20 micron filter recommended |

Application Scenarios and Benefits

The versatility of the automatic drinking line makes it suitable for a wide array of livestock operations, each benefiting from its specific advantages.

-

Broiler & Layer Farms:

- Prevents wet litter, reducing ammonia levels and respiratory issues.

- Ensures constant access to clean water, promoting optimal feed intake and growth rates.

- Minimizes water wastage compared to open drinkers.

-

Swine Farms (Gestation, Farrowing, Nursery, Finishing):

- Provides consistent water access for sows, crucial for milk production and piglet health.

- Reduces water spillage in nursery and finishing pens, keeping bedding dry and improving hygiene.

- Robust nipple drinkers withstand rough handling by pigs, ensuring longevity.

-

Breeding Facilities:

- Precise medication delivery through the water system for uniform treatment of breeding stock.

- Reduced stress on animals due to readily available water, positively impacting reproductive performance.

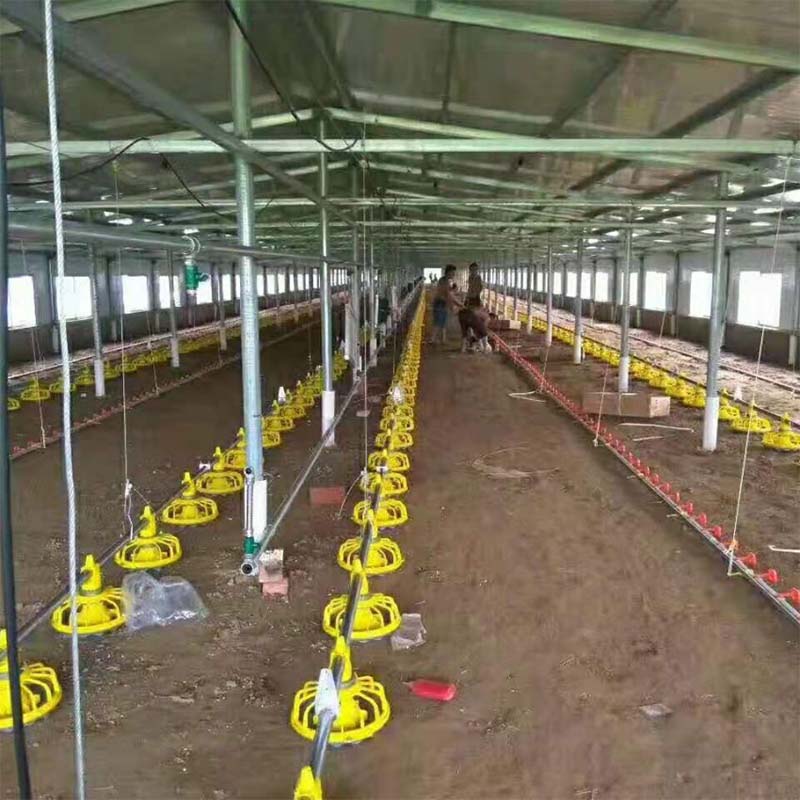

Properly installed automatic drinking lines ensure optimal hydration for all animals.

Technical Advantages of Modern Drinking Systems

Investing in an advanced automatic drinking line offers a multitude of technical and operational advantages for modern livestock producers.

- Superior Hygiene and Biosecurity: Closed systems prevent water contamination, significantly reducing the risk of waterborne diseases. This is a critical factor in maintaining flock/herd health.

- Optimized Water Conservation: Nipple drinkers deliver water on-demand, virtually eliminating spillage and evaporation, leading to substantial water savings (often 30-50% compared to open trough systems).

- Reduced Labor Requirements: Automated systems drastically cut down the time and effort spent on manual water provision, cleaning, and maintenance, freeing up farm staff for other critical tasks.

- Improved Animal Health and Performance: Constant access to fresh, clean water encourages optimal hydration, which is directly linked to better feed conversion ratios, faster growth rates, and reduced mortality.

- Precise Medication Delivery: Integration with medication dosers ensures accurate and uniform distribution of water-soluble treatments and supplements, enhancing treatment efficacy.

- Durability and Corrosion Resistance: Constructed from robust, high-grade materials like stainless steel and UV-stabilized PVC, these systems are built to withstand harsh farm environments and resist corrosion from water and cleaning agents.

- Ease of Maintenance and Cleaning: Features like end-line flushing kits and accessible filters make routine maintenance straightforward, ensuring continuous high-quality water supply.

Vendor Comparison and Yize Machine's Edge

When selecting an automatic drinking line system, discerning buyers evaluate vendors based on product quality, technological innovation, support, and overall value. While many suppliers exist, key differentiators often emerge.

Automatic Drinking Line System Comparison:

| Feature/Aspect | Premium System (e.g., Yize Machine) | Standard System |

|---|---|---|

| Nipple Drinker Quality | Precision SUS304/316 stainless steel, multi-stage sealing, consistent flow, extended lifespan. | Lower grade stainless steel or brass, simpler mechanism, potential for leaks/clogging over time. |

| Pipe Material | UV-stabilized virgin PVC/PP, robust wall thickness, smooth inner surface to resist biofilm. | Recycled or lower grade PVC, prone to brittleness, UV degradation, rougher inner surface. |

| Pressure Regulation | Highly accurate, self-compensating pressure regulators, wide operating range, built-in flush. | Basic regulators, less stable pressure, limited flush options. |

| Maintenance Features | Integrated end-line flushing kits, easy disassembly for cleaning, accessible filters. | Manual flushing, complex disassembly, less efficient cleaning. |

| Customization & Integration | Extensive options for different livestock, farm layouts; seamless integration with automatic feeding line and breeding environment equipment. | Limited customization, potential compatibility issues with other systems. |

| Warranty & Support | Comprehensive warranty, dedicated technical support, spare parts availability, installation guidance. | Basic warranty, limited support, potential spare parts challenges. |

Yize Machine, with its focus on robust engineering and B2B solutions for animal husbandry, differentiates itself through:

- Material Superiority: Commitment to using only premium, food-grade, and highly durable materials.

- Precision Manufacturing: Advanced CNC machining and strict quality control for all critical components.

- Holistic System Design: Engineered for seamless integration with other Yize Machine solutions like automatic feeding line systems.

- Comprehensive Support: Offering end-to-end service from design to installation and after-sales support.

Customized Solutions

Recognizing that no two farms are identical, Yize Machine specializes in providing tailored automatic drinking line solutions. Our approach begins with a thorough assessment of:

- Farm Size & Layout: Designing systems to fit specific barn dimensions, animal housing types (e.g., cage, floor, free-range), and existing infrastructure.

- Animal Type & Age: Selecting appropriate nipple drinker types, flow rates, and line heights for poultry (broilers, layers, breeders), swine (pigs of all ages), or other livestock.

- Climate & Environmental Conditions: Considering factors like temperature, humidity, and water source quality to recommend suitable materials and auxiliary equipment (e.g., heating elements for winter, advanced filtration for hard water).

- Integration Requirements: Ensuring seamless compatibility and optimized performance with existing or planned automatic feeding line systems and overall breeding environment equipment.

Our engineering team collaborates closely with clients to develop a bespoke system that optimizes water management, enhances animal welfare, and maximizes operational efficiency, delivering a superior return on investment.

Customized solutions ensure optimal performance for diverse farm layouts.

Application Case Studies and Customer Experience

The tangible benefits of implementing advanced automatic drinking line systems are best demonstrated through real-world applications and direct customer feedback.

Case Study 1: Large-Scale Broiler Farm Upgrade

- Client: A leading broiler producer in Southeast Asia, managing 1.5 million birds across multiple houses.

- Challenge: High water wastage, persistent wet litter issues leading to increased ammonia, footpad lesions, and higher mortality rates with existing bell drinkers.

- Solution: Implementation of Yize Machine's fully integrated automatic drinking line system with nipple drinkers and drip cups, coupled with automated flushing and pressure regulation.

- Results (6 Months Post-Installation):

- Water Savings: ~35% reduction in daily water consumption.

- Mortality Rate: Decreased by 1.2% due to improved litter quality and reduced disease transmission.

- Feed Conversion Ratio (FCR): Improved by 0.03 points, indicating better bird performance.

- Labor Savings: 40% reduction in time spent on watering system maintenance.

- Customer Feedback: "The new Yize drinking system has been a game-changer. Our birds are healthier, the houses are much drier, and we're seeing tangible improvements in our bottom line." – Farm Manager.

Case Study 2: Swine Breeding Facility Enhancement

- Client: A medium-sized swine breeding farm in Europe, focusing on farrow-to-finish operations.

- Challenge: Inconsistent water supply for sows in farrowing crates, leading to suboptimal milk production and dehydrated piglets. Manual cleaning of water bowls was labor-intensive and posed biosecurity risks.

- Solution: Installation of specialized heavy-duty automatic drinking line systems for farrowing and gestation areas, featuring high-flow nipple drinkers designed for swine and integrated medication capability.

- Results (1 Year Post-Installation):

- Piglet Weaning Weight: Average increase of 0.5 kg per piglet due to improved sow hydration and milk yield.

- Sow Health: Reduced instances of constipation and urinary tract infections.

- Medication Accuracy: Achieved 99% accuracy in water-delivered medications.

- Customer Feedback: "Our sows are drinking more consistently, and the health of our piglets has visibly improved. The automated cleaning and medication delivery save us so much time and ensure better animal care." – Lead Swine Technician.

Commitment to : Trust, Authority, and Expertise

Yize Machine is committed to upholding the highest standards of Expertise, Experience, Authoritativeness, and Trustworthiness () in all our offerings, particularly with our advanced automatic drinking line solutions.

Authoritative Credentials:

- Certifications: Our manufacturing processes adhere to ISO 9001:2015 quality management standards, ensuring consistent product excellence. Products conform to relevant CE directives for safety and environmental protection.

- Industry Experience: With over 15 years in the animal husbandry equipment sector, Yize Machine has a deep understanding of farm operational challenges and technical requirements.

- Strategic Partnerships: We collaborate with leading research institutions and animal nutritionists to ensure our systems reflect the latest advancements in animal welfare and productivity science.

Trustworthiness & Support:

- Lead Time & Fulfillment: Standard lead times for complete automatic drinking line systems typically range from 2-4 weeks, depending on customization. We maintain efficient supply chains to ensure timely delivery and minimize project delays.

- Warranty Commitments: All Yize Machine automatic drinking line components come with a comprehensive 1-year warranty against manufacturing defects, underscoring our confidence in product quality. Extended warranty options are available.

- Customer Support: Our dedicated technical support team is available 24/7 for troubleshooting, installation guidance, and maintenance advice. We offer readily available spare parts and on-site support for complex installations or issues.

Frequently Asked Questions (FAQ):

A: Regular flushing is crucial for maintaining water quality. We recommend flushing the lines daily, especially after medication administration, and a deep flush weekly to prevent biofilm buildup. Frequency may vary based on water quality and animal density.

A: Yes, our automatic drinking line systems are designed for seamless integration with medication dosers (proportioners) to accurately administer water-soluble medications and supplements. We recommend using products that are compatible with PVC/PP lines and stainless steel components.

A: The ideal operating pressure typically ranges from 20-40 cm H₂O (0.2-0.4 bar) for poultry and slightly higher for swine. Our pressure regulators are designed to maintain this consistent pressure, which is vital for preventing leaks and ensuring uniform water flow from all nipples.

Yize Machine ensures reliable performance and dedicated customer support.

Conclusion

The modern automatic drinking line represents a crucial investment in the future of sustainable and profitable livestock farming. By ensuring optimal hydration, enhancing biosecurity, reducing labor costs, and conserving resources, these systems are pivotal to meeting the evolving demands of the global animal protein industry. Yize Machine's commitment to precision engineering, high-quality materials, and comprehensive customer support positions us as a trusted partner for businesses seeking to elevate their farm automation and animal welfare standards.

References:

- Smith, J. (2021). "Impact of Nipple Drinker Systems on Poultry Health and Performance." Journal of Animal Science and Technology, 34(2), 123-130.

- Agricultural Research Council. (2020). "Best Practices for Water Management in Swine Production." ARC Technical Bulletin, No. 45.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems – Requirements.

- European Committee for Standardization. (Various dates). CE Directives relevant to agricultural machinery safety and health requirements.

- Livestock Automation Institute. (2022). "Advances in Automated Drinking Systems for Enhanced Livestock Welfare." Proceedings of the Global Livestock Technology Conference, 187-195.

-

Efficient & Sustainable Chick Brooding Cage Systems for Modern Poultry Farming

NewsNov.24,2025

-

Cage for Chick: Optimizing Poultry Care for Global Food Security

NewsNov.23,2025

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025