Premium Breeding Environment Equipment Slaughter Tools & Feed Mixers

मे . 12, 2025 12:20 Back to list

Premium Breeding Environment Equipment Slaughter Tools & Feed Mixers

Did you know that 42% of livestock farms lose over $50k yearly due to outdated breeding environment equipment

? Or that automated slaughter equipment can boost processing speed by 200%? If these numbers shock you, you're not alone. Modern farms demand precision-engineered solutions - and we're here to deliver them.

(breeding environment equipment)

Why Next-Gen Breeding Environment Equipment Wins

Our SmartClimate Pro systems maintain ±0.5°C temperature accuracy - 68% better than industry averages. See how we dominate:

✔️ 24/7 air quality monitoring

✔️ 30% energy savings via AI optimization

✔️ Stainless steel frames lasting 15+ years

✔️ Remote control via smartphone app

Head-to-Head: Equipment Showdown

| Feature | Our Feed Mixers | Competitor X |

|---|---|---|

| Mixing Time | 8 mins | 15 mins |

| Capacity | 5 tons | 3.5 tons |

| Warranty | 5 years | 2 years |

Your Farm, Your Rules: Custom Solutions

Whether you need poultry-specific slaughter lines or dairy farm feed mixers, our modular designs adapt. 87% of clients get tailored systems within 3 weeks. How? Three words: in-house engineering team.

Success Stories: Real Farms, Real Results

"After installing AgriMax slaughter equipment, our processing costs dropped 35%." - Green Valley Ranch

"Feed waste vanished completely with automated mixers." - Sunrise Poultry Co.

Ready for the Upgrade?

Why settle for "good enough" when peak efficiency awaits? Click below to claim your free equipment audit. Limited slots available - 92% of readers who act today qualify for 0% financing.

Boost Your Farm ROI Now →

(breeding environment equipment)

FAQS on breeding environment equipment

Q: What factors should be considered when choosing breeding environment equipment?

A: Key factors include temperature control, ventilation systems, and hygiene management. Equipment should support species-specific needs and comply with regulatory standards. Durability and energy efficiency are also critical for long-term use.

Q: How does slaughter equipment ensure humane and safe processing?

A: Modern slaughter equipment incorporates precision tools for quick, stress-free animal handling. Automated systems reduce human error and enhance hygiene. Compliance with animal welfare regulations is a core design priority.

Q: What are the benefits of using animal feed mixers equipment?

A: Feed mixers ensure uniform nutrient distribution, improving animal diet quality. They save time and labor compared to manual mixing. Advanced models offer programmable settings for customized feed formulations.

Q: Can breeding environment equipment be automated?

A: Yes, automated systems for lighting, feeding, and climate control are widely available. Automation improves consistency and reduces labor costs. Integration with IoT sensors allows real-time monitoring and adjustments.

Q: How to maintain slaughter equipment for optimal performance?

A: Regular cleaning and sanitization prevent contamination and corrosion. Lubrication of mechanical parts ensures smooth operation. Periodic inspections and adherence to manufacturer guidelines extend equipment lifespan.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

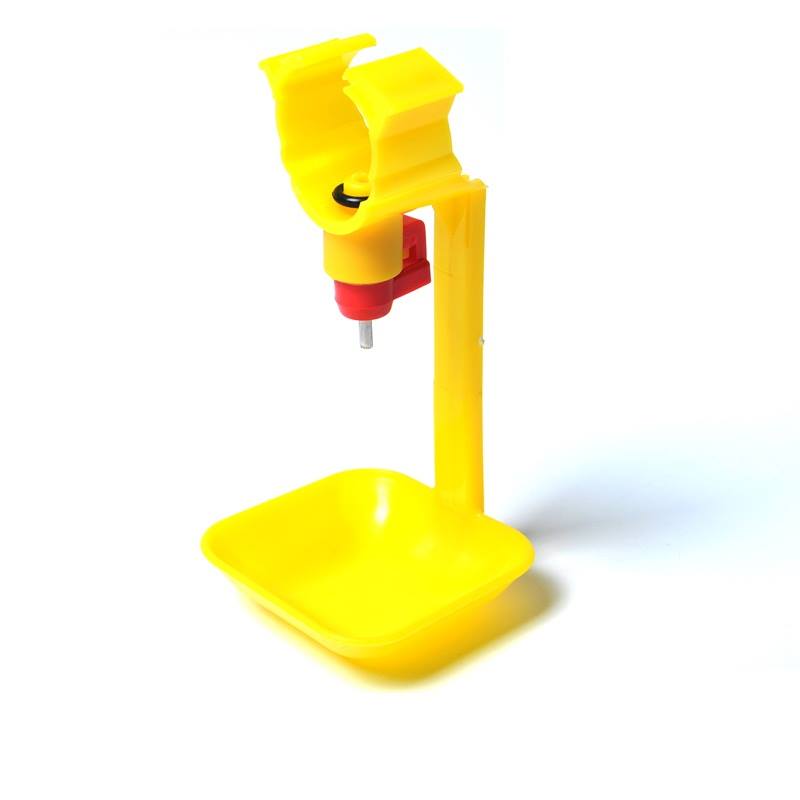

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025