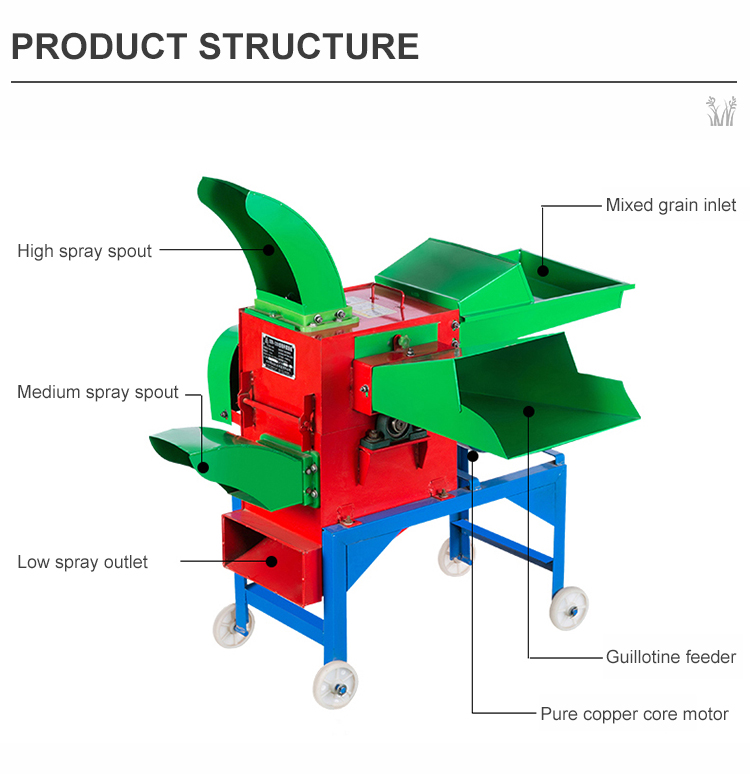

Feed hay chopper kneading silk crushing machinery main structure of is that the chopping blade, kneading blade and crushing blade are installed on a spindle, which saves space. Various blades are also convenient for disassembly, maintenance and replacement. The chopping blade is perpendicular to the feed port for easy cutting. The kneading blade and crushing hammer are parallel to the feed port for easy crushing of grass kneading and granular products.

|

Name |

Production capacity kg/h |

Size mm |

Power kw |

Weight kg |

|

Type 500 |

350-700 |

820*920*1500 |

2.2-4.8 |

62 |

|

Type 580 |

450-800 |

1150*920*1500 |

3-4.8 |

78 |

|

Type 680 |

600-900 |

135*1100*1500 |

3-4.8 |

88 |

|

Type 690 |

400-600 |

1150*1000*1430 |

3/4/4.5 |

70 |

|

Type 750 |

500-800 |

1200*1000*1580 |

3/4/4.5 |

80 |

what is this product?

Application of chaff cutter

A chaff cutter is a valuable agricultural tool used to cut straw, hay, and other forage materials into smaller, more manageable pieces. These cuttings can then be used as livestock feed or bedding material. Chaff cutters are commonly employed in animal farming to enhance the digestibility of forage and reduce waste. They promote efficient feeding practices and help ensure that animals receive a balanced and nutritious diet, contributing to their health and overall productivity.

this product application?

How to choose chaff cutter for your farm ?

When selecting a chaff cutter for your farm, consider capacity, power source, and durability. Determine the machine's capacity to meet your farm's daily forage cutting needs. Choose between electric, PTO-driven, or engine-powered models based on your power source and operational preferences. Opt for a cutter made from robust materials like high-quality steel for longevity. Ensure it's easy to clean and maintain. Evaluate the size and design to fit your farm's layout and space constraints. Consider your budget and long-term requirements while selecting a chaff cutter suitable for your farm.