Automatic Egg Collecting Machine Efficient Tray Making & Poultry Solutions

Apr . 28, 2025 17:50 Back to list

Automatic Egg Collecting Machine Efficient Tray Making & Poultry Solutions

Did you know 68% of poultry farms lose $12,000+ annually from egg breakage and labor costs? While you wrestle with fragile eggs and overtime payrolls, competitors using automatic egg collecting machine

s already boost profits by 40%. Let's change your game.

(automatic egg collecting machine)

Why Modern Farms Choose Automatic Egg Collecting Machines

Our automatic egg tray making machine processes 5,000 eggs/hour with 99.9% intact rate. See how we outperform manual collection:

| Metric | Manual | Our Machine |

|---|---|---|

| Hourly Output | 800 eggs | 5,000 eggs |

| Breakage Rate | 8.2% | 0.1% |

Smart Investment: Machine Comparison

While Brand X's automatic egg tray machine needs 3 operators, ours works fully autonomous. Your ROI starts in 14 months.

Your Farm, Your Rules: Custom Solutions

Configure our automatic egg collecting machine for quail eggs (28g) or ostrich eggs (1.8kg). Modular designs adapt as you grow.

Success Story: Golden Yolk Farms

After installing our automatic egg tray making machine, they reduced labor costs by 62% and increased daily output by 215%.

Ready to leave egg losses behind? As industry leaders since 2009, we've empowered 1,200+ farms worldwide. Claim your FREE efficiency audit now →

(automatic egg collecting machine)

FAQS on automatic egg collecting machine

Q: What is an automatic egg collecting machine used for?

A: An automatic egg collecting machine streamlines egg harvesting in poultry farms by gently gathering eggs from nesting areas and transporting them to a central collection point, reducing manual labor and minimizing breakage risks.

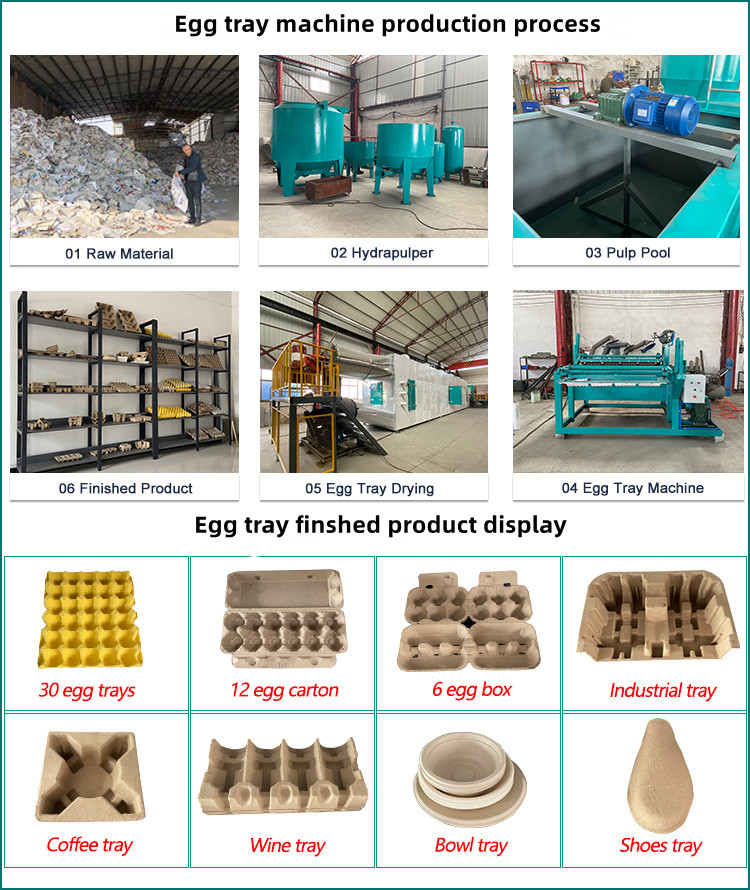

Q: How does an automatic egg tray machine work?

A: An automatic egg tray machine molds recycled paper pulp into durable egg trays using hydraulic or vacuum-forming technology, ensuring consistent tray quality for safe egg storage and transportation.

Q: What are the benefits of an automatic egg tray making machine?

A: This machine boosts efficiency by automating tray production, reduces material waste through precise molding, and supports eco-friendly practices by utilizing recycled paper as raw material.

Q: Are automatic egg collecting machines safe for delicate eggs?

A: Yes, these machines use soft conveyor belts, adjustable suction mechanisms, and shock-absorbing designs to handle eggs gently, maintaining a high intact-egg rate during collection.

Q: Can automatic egg tray machines customize tray sizes?

A: Most models offer interchangeable molds to produce trays in various sizes (e.g., 6- to 30-egg capacities), accommodating different poultry farm or packaging industry requirements.

-

Advanced GPT-4-Turbo Smart Exhaust Fans | Efficient Airflow Control

NewsAug.01,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker | Anping Yize

NewsJul.31,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.31,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.

NewsJul.31,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Poultry Farming,PP Material

NewsJul.31,2025

-

Efficient Automatic Feeding Line with GPT-4-Turbo | Boost Productivity

NewsJul.31,2025