Efficient Animal Feed Production Equipment for Sustainable Agriculture Solutions

11-р сар . 29, 2024 15:28 Back to list

Efficient Animal Feed Production Equipment for Sustainable Agriculture Solutions

The Evolution and Importance of Animal Feed Processing Machines

In the realm of agriculture and livestock management, the role of animal feed processing machines has become increasingly pivotal. These machines are designed to enhance the efficiency and quality of animal feed production, addressing the growing demand for high-quality feed to support livestock health and productivity. As the global population continues to rise, the pressure on food production systems also increases, making innovative solutions in animal feed processing more vital than ever.

Understanding Animal Feed Processing Machines

Animal feed processing machines encompass a range of equipment used to prepare, produce, and package feed for various types of livestock, including cattle, poultry, swine, and aquaculture. The processing involves various steps such as grinding, mixing, pelleting, and extruding ingredients to create balanced and nutritious feed that meets the specific dietary requirements of animals.

At its core, the feed processing system is designed to optimize the size and consistency of feed particles, ensuring that nutrients are easily digestible. This process maximizes feed efficiency and reduces wastage, ultimately leading to healthier livestock and higher yield in meat, milk, and eggs.

Key Components of Animal Feed Processing Machines

1. Grinders and Mills These machines are critical for reducing raw materials into smaller, manageable sizes. Different types of grinders, such as hammer mills and roller mills, ensure that ingredients are uniformly processed, which is essential for proper mixing and pellet formation.

2. Mixers After grinding, the feed ingredients must be mixed thoroughly to ensure an even distribution of nutrients. Horizontal and vertical mixers are commonly used, with each configuration offering unique advantages in terms of efficiency and output quality.

3. Pelletizers Pelletizing is a crucial step in feed processing, as it significantly improves the feed's digestibility and handling characteristics. Pelletizers apply heat and pressure to compact the mixed ingredients into pellets. This not only enhances nutrient absorption but also reduces sorting and wastage when feeding livestock.

4. Extruders For certain types of feed, especially for aquaculture and specialty diets, extruders are used. These machines cook and shape the feed through a process that includes high temperature and moisture, resulting in floating or sinking feeds that cater to aquatic animals.

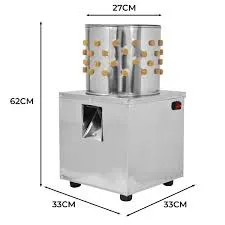

animal feed processing machine

5. Cooling and Packaging Equipment Once the feed has been processed, it must be cooled to preserve its quality and prevent spoilage. Cooling systems followed by packaging solutions ensure that the final product is ready for distribution and retains its nutritional value.

The Benefits of Modern Animal Feed Processing Machines

The integration of advanced technology in animal feed processing machines has revolutionized the industry. Modern machines offer several benefits

- Increased Efficiency Automation and advanced control systems allow for continuous production and monitoring, significantly increasing the throughput and minimizing labor costs.

- Customization Feed formulation can be tailored to meet specific nutritional requirements for different livestock, enhancing the overall health and productivity of the animals.

- Quality Control Sophisticated monitoring systems ensure that every batch of feed meets stringent safety and nutritional standards, reducing the risk of contamination and improving animal welfare.

- Sustainability Advanced feed processing technology often includes the use of by-products from other industries, reducing waste and promoting a circular economy within food production.

Conclusion

The animal feed processing machine industry plays a crucial role in the agricultural supply chain, providing essential tools to produce feed that supports animal health and enhances food security. As technology continues to advance, so too will the capabilities of feed processing machines, paving the way for more efficient, sustainable, and high-quality livestock production. In a world where the demand for food is ever-increasing, the importance of these machines cannot be overstated—they are, quite literally, the backbone of profitable and responsible animal agriculture.

-

Automatic Feeding Line System - Anping Yize | Efficiency&Durability

NewsJul.29,2025

-

Automatic Feeding Line System - Anping Yize|Poultry Efficiency&Durability

NewsJul.29,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Durable PP Material&Easy Maintenance

NewsJul.29,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025