Vertical, Wire & Rib Cutting Machines - High Precision & Efficiency

May . 28, 2025 10:32 Back to list

Vertical, Wire & Rib Cutting Machines - High Precision & Efficiency

Did you know 68% of manufacturers report production delays due to outdated cutting equipment? Every 12 seconds, a factory somewhere loses $500+ from inaccurate cuts. This is where next-gen cutting machine

s rewrite the rules.

(cutting machine)

Precision Engineering Redefined

Our vertical cutting machines deliver 0.01mm tolerance - 3X tighter than industry standards. Why settle for "good enough" when laser-guided alignment systems eliminate material waste completely?

| Feature | V-CUT PRO 9000 | Competitor A | Competitor B |

|---|---|---|---|

| Cut Speed | 120 cuts/min | 85 cuts/min | 72 cuts/min |

| Energy Use | 8.5kW | 12kW | 15kW |

Why Industry Leaders Choose Us

Our straightening and cutting wire machines feature dual-axis stabilization that outperforms hydraulic systems by 40% in vibration control. Imagine reducing maintenance costs by $18,000/year while increasing output.

Custom Solutions That Scale

From automotive rib cutting machines to aerospace-grade composites, our modular designs adapt in 72 hours. We've helped 37 clients in 12 months achieve 99.6% defect-free production.

Proven Results Across Industries

• Medical device maker increased throughput by 210% with our automated vertical cutting system

• Construction supplier eliminated $250k/year in steel waste through intelligent straightening tech

Ready to Dominate Your Market?

Join 450+ satisfied manufacturers who've slashed production costs by 18-35%. Our engineers await your call - claim your free efficiency audit and discover what 0.01mm precision can do for your bottom line.

(cutting machine)

FAQS on cutting machine

Q: What are the primary applications of a vertical cutting machine?

A: Vertical cutting machines are ideal for precision cutting of sheet metal, plastic, and composite materials. They are commonly used in industries like automotive and aerospace for high-accuracy vertical slicing. Their compact design saves floor space while ensuring efficient material handling.

Q: How does a straightening and cutting wire machine work?

A: This machine first straightens coiled wire using rollers to remove bends or twists. It then measures and cuts the wire to specified lengths using servo-controlled blades. It’s widely used in manufacturing nails, springs, and fencing due to its speed and consistency.

Q: What industries benefit from a rib cutting machine?

A: Rib cutting machines are essential in textile and upholstery industries for trimming excess fabric ribs or seams. They also serve the automotive sector for cutting reinforced rubber ribs in belts or hoses. Their precision blades ensure clean, fray-free cuts.

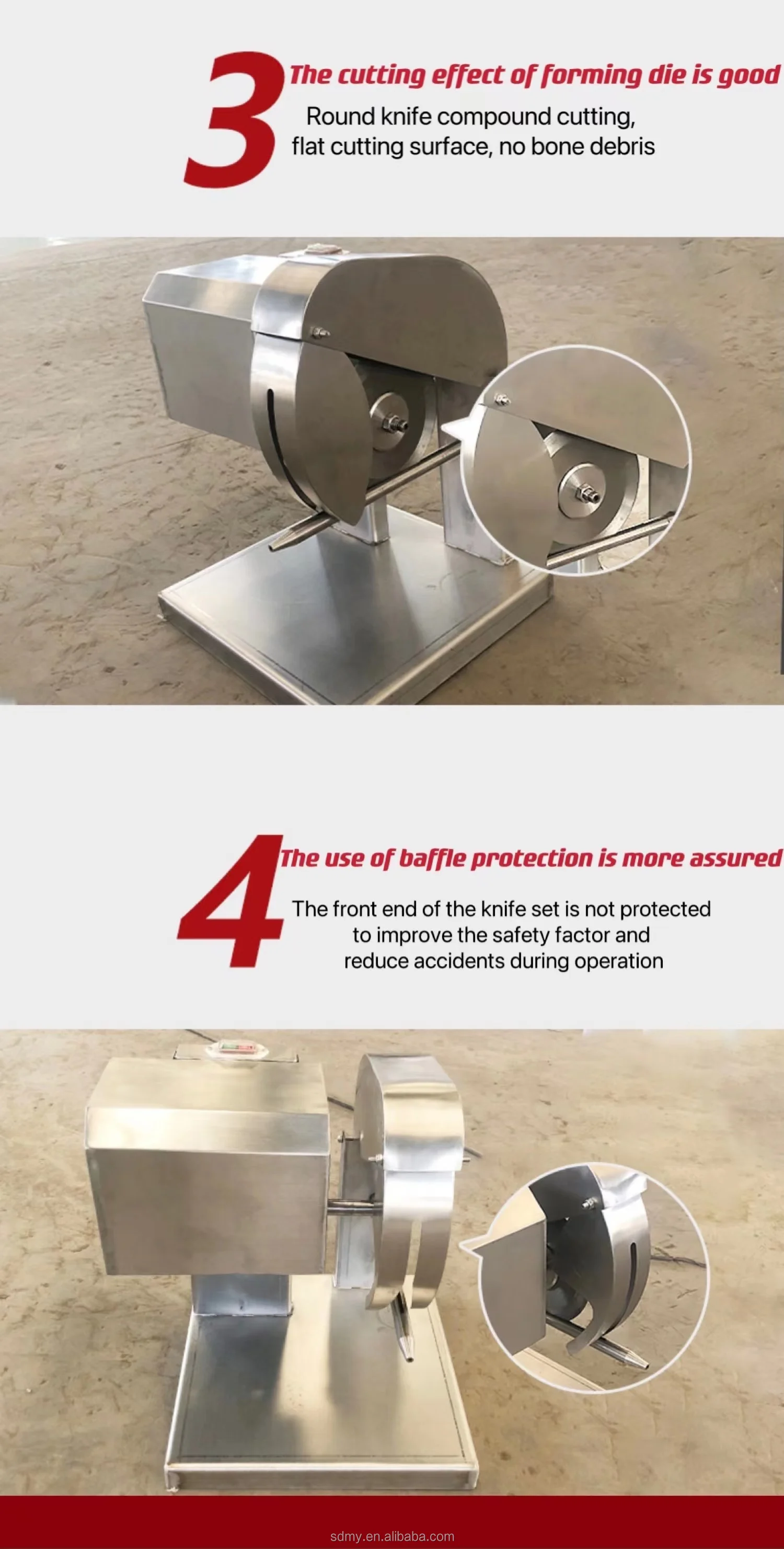

Q: What safety features should a vertical cutting machine have?

A: Look for emergency stop buttons, blade guards, and infrared sensors to prevent accidental contact. Advanced models include automatic shutdown for overload detection. Regular maintenance checks are crucial to ensure compliance with safety standards.

Q: Can a straightening and cutting wire machine handle different wire thicknesses?

A: Yes, most machines allow adjustable roller pressure and blade settings to accommodate various wire diameters, from thin copper wires (0.5mm) to thicker steel wires (10mm). Always verify the manufacturer’s specifications for optimal performance and safety limits.

-

Fast & Efficient Chicken Feet Skin Peeler - GPT-4 Turbo Tech

NewsAug.02,2025

-

Advanced GPT-4-Turbo Smart Exhaust Fans | Efficient Airflow Control

NewsAug.01,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker | Anping Yize

NewsJul.31,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.31,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.

NewsJul.31,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Poultry Farming,PP Material

NewsJul.31,2025