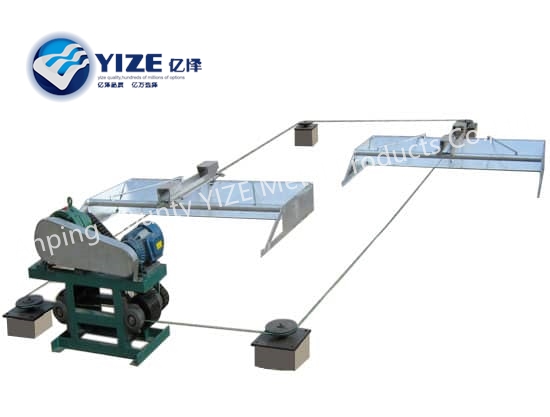

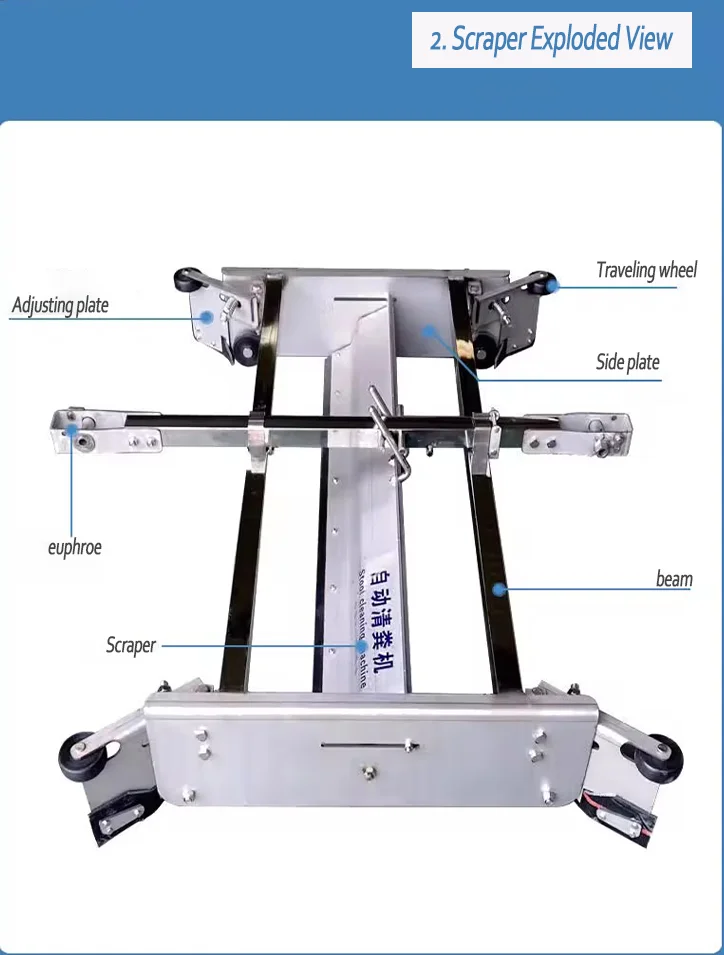

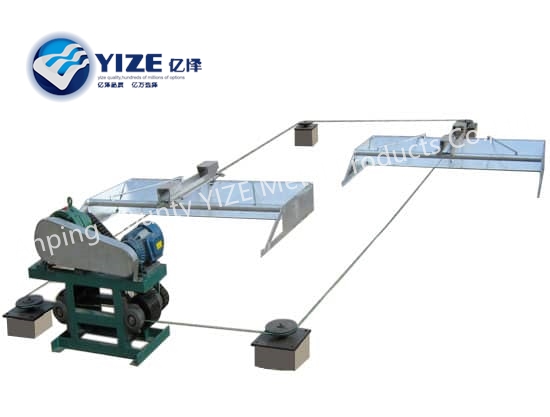

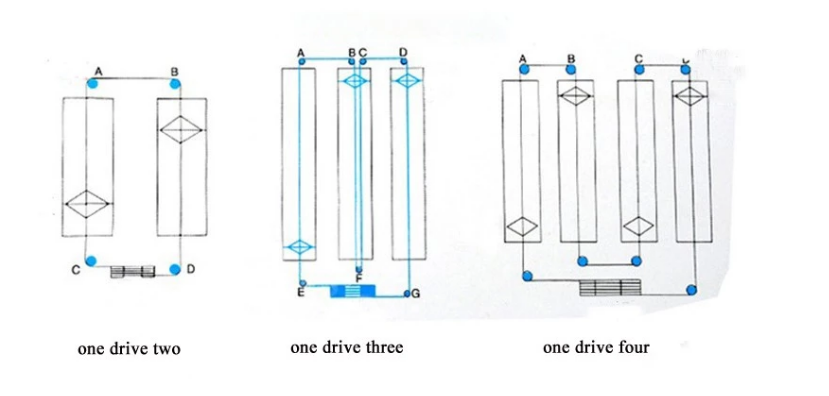

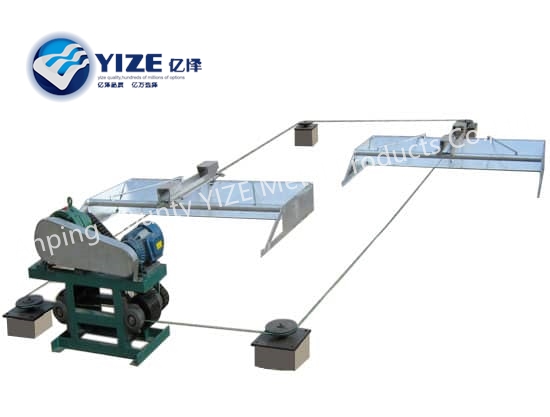

Automatic manure scraper’s scraper plate all are equipped with width adjusting plate. The scraper width would be adjusted according to the width of the manure ditch. The adjust-able extent will be 70-80mm.

It effectively avoids the running obstacles caused by the non-standard construction of the manure pit.

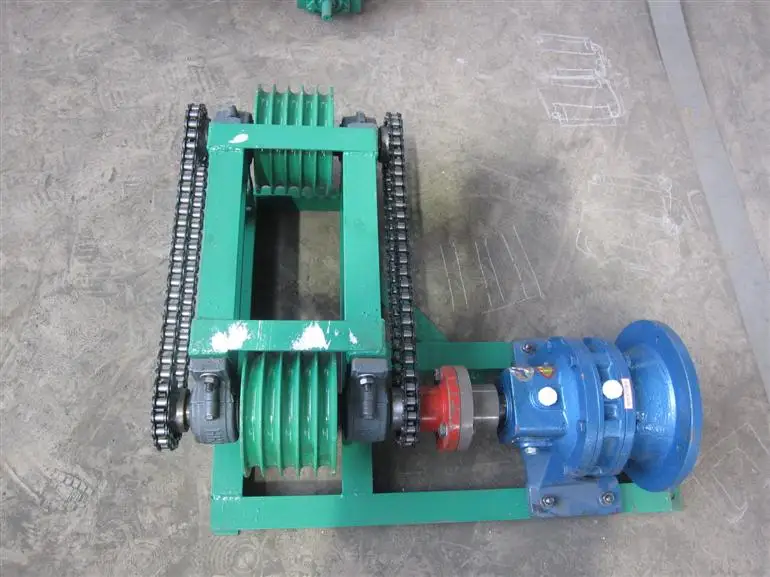

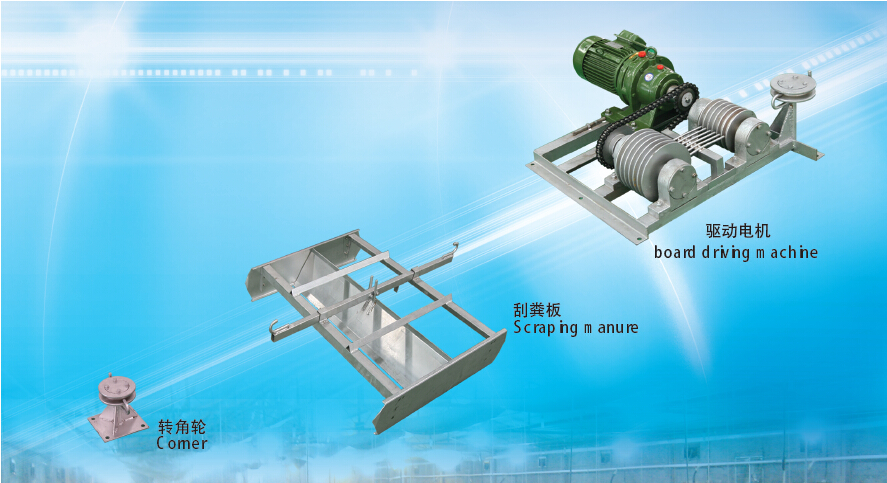

Automatic manure scrapers driving component and scraper are made by SS304 and 275g galvanized steel material optional.

|

Product Name |

Farms Automatic Manure Scraper |

|

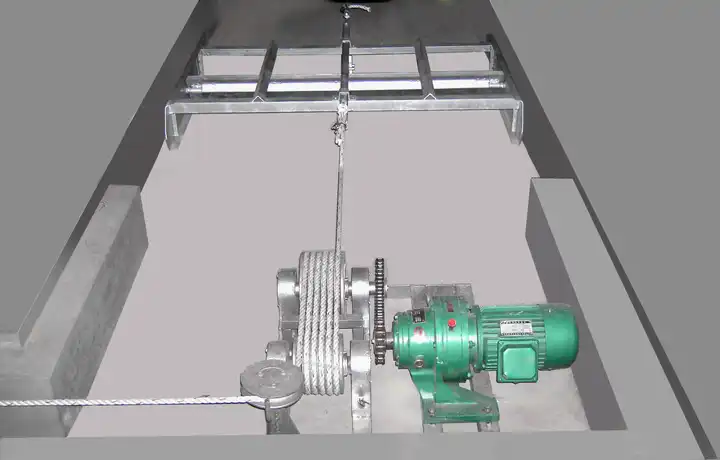

Motor |

Waterproof motor cooper wire gear motor |

|

Voltage |

380V/220V |

|

Manure scrapper Width |

1m to 2.4m or as customized |

|

Motor power |

1.5kw/3kw |

|

Product Advantage |

Wear resistance, corrosion resistance, long life, great strength, labor saving, simple and practical. |

what is this product?

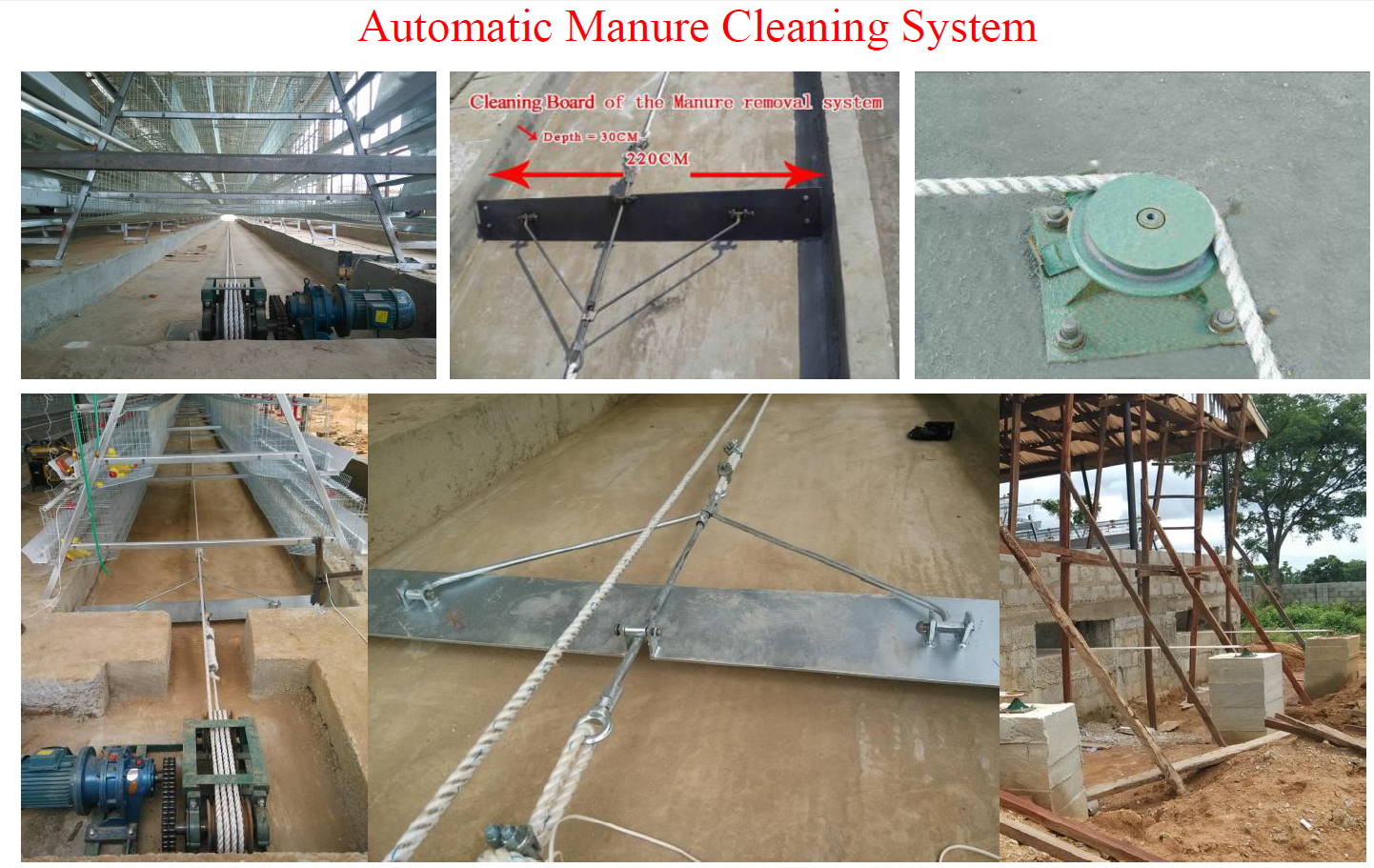

Application of Chicken Cages

Manure scraper cleaning machines are used in agriculture, particularly in livestock farming, for automated removal of manure from barns and pens. Key applications include dairy, poultry, and swine farms, as well as equine facilities and cattle feedlots. These machines enhance hygiene, prevent disease spread, and save time and labor. Additionally, they contribute to waste management and environmental sustainability. Integration with farm automation systems allows for scheduled and efficient cleaning cycles. Overall, manure scraper cleaning machines play a vital role in maintaining a clean and healthy environment for animals while optimizing farm operations.

this product application?

How to choose layer cages for your poultry farm ?

When choosing a manure scraper cleaning machine for your poultry farm:

Farm Size and Layout:

Ensure the machine's capacity and reach match your farm's dimensions.

Type of Poultry Housing:

Select a machine compatible with your specific poultry housing system.

Automation and Integration:

Decide between manual or automated systems based on your preferences and needs.

Manure Disposal System:

Choose a system aligned with your waste management strategy.

Cleaning Mechanism:

Evaluate and select a mechanism (chain-driven, rope-driven, hydraulic) based on durability and efficiency.

Build Quality and Materials:

Prioritize robust and corrosion-resistant construction for durability.

Ease of Maintenance:

Opt for a machine with accessible parts and simple maintenance procedures.

Manure Depth and Type:

Consider the machine's ability to handle the depth and type of manure in your poultry house.

Power Source:

Choose a power source (electric, hydraulic, PTO-driven) that aligns with your farm's infrastructure.

Budget Considerations:

Establish a budget and compare models for cost-effectiveness.

Manufacturer Reputation:

Choose a reputable manufacturer with a track record of reliability.

By considering these factors, you can choose a manure scraper cleaning machine that efficiently meets your poultry farm's specific requirements.