Optimal Techniques for Poultry Scalder Operation to Enhance Efficiency and Quality in Processing Industry

Lie . 30, 2024 00:21 Back to list

Optimal Techniques for Poultry Scalder Operation to Enhance Efficiency and Quality in Processing Industry

The Importance of Poultry Scalders in Processing Facilities

Poultry processing is a critical industry that requires precision, efficiency, and adherence to hygiene standards. Among the various stages involved in poultry processing, scalding plays a vital role. Poultry scalders are essential machines designed to facilitate the removal of feathers from birds like chickens, turkeys, and ducks after they have been slaughtered. This article aims to discuss the importance of poultry scalders, exploring their functionality, benefits, and impact on the poultry industry.

The Functionality of Poultry Scalders

Poultry scalders work by immersing birds in hot water at specific temperatures for a predetermined period. The temperature is crucial; typically, it ranges between 140°F (60°C) and 160°F (71°C), depending on the type of poultry and the desired results. The scalding process essentially relaxes the skin and feathers, making them easier to remove during plucking. A successful scalding process not only ensures that feathers are effectively removed but also helps preserve the quality of the meat by minimizing bruising and damage.

The Benefits of Using Poultry Scalders

1. Efficiency in Processing Scalders drastically reduce the time it takes to prepare birds for further processing. Manual feather removal methods can be labor-intensive and time-consuming. In contrast, using scalders allows facilities to process larger volumes of poultry in a shorter timeframe.

2. Improved Meat Quality The scalding process helps maintain the integrity of the poultry skin and muscle tissue. By facilitating easier feather removal without damaging the meat, scalders play a crucial role in ensuring that the final product meets high-quality standards.

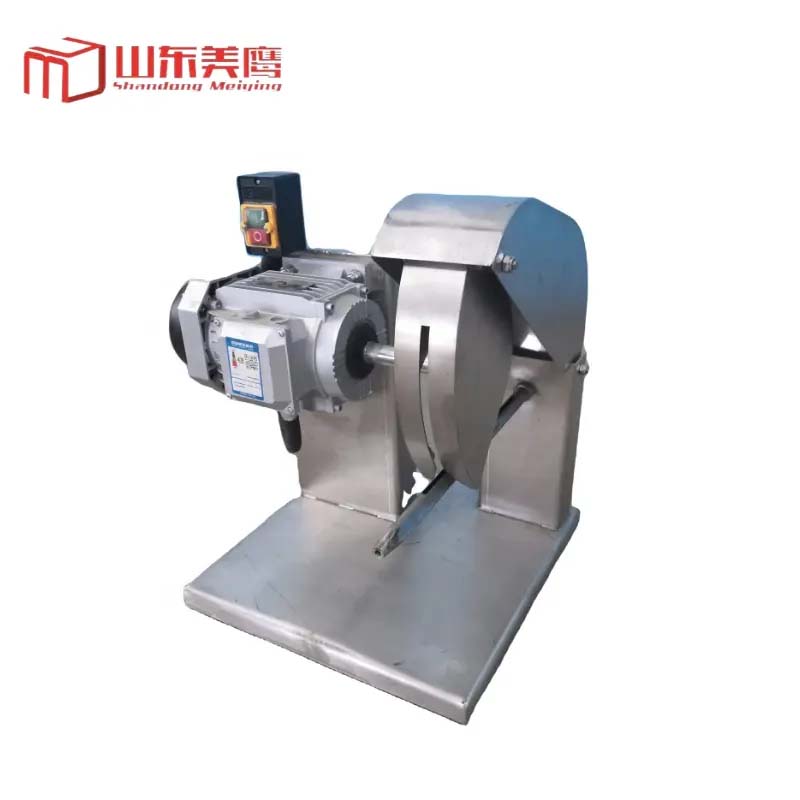

poultry scalder

3. Hygienic Conditions In the poultry industry, hygiene is of utmost importance. Scalding can eliminate surface bacteria and pathogens present on the skin, leading to safer products for consumers. When combined with appropriate sanitation practices, the use of scalders significantly enhances food safety.

4. Cost-Effectiveness By automating the scalding and feather removal process, poultry processing facilities can reduce labor costs and associated expenses. Increased efficiency also translates to lower operational costs, making it a cost-effective solution for processors.

The Impact on the Poultry Industry

The introduction and evolution of poultry scalders have transformed the poultry industry significantly. With advancements in technology, modern scalders are equipped with features like temperature controls, timers, and even recycling systems that conserve water and energy. These improvements contribute to sustainable practices within the industry, aligning with the growing demand for environment-friendly operations.

Moreover, poultry scalders have paved the way for the expansion of poultry processing facilities worldwide. As more countries embrace mechanization and automation, the demand for poultry products continues to rise. In regions where poultry farming is a critical part of the economy, efficient processing methods, facilitated by scalders, contribute to employment opportunities and support local economies.

Conclusion

Poultry scalders are indispensable in the poultry processing industry. Their ability to enhance efficiency, improve meat quality, ensure hygiene, and reduce costs makes them a vital component of modern poultry facilities. As the industry continues to embrace technological advancements, the role of scalders will remain pivotal in meeting the growing demand for poultry products and ensuring consumer safety. As we look toward the future, the evolution of poultry scalders will undoubtedly continue to impact the industry positively, aligning with the needs of processors and consumers alike.

-

High Performance Exhaust Fan – Efficient Ventilation Solutions for Home

NewsJun.10,2025

-

High-Quality Gestation Pen for Sows Durable Mobile Pig Pen & Simple Pig Pen Solutions

NewsJun.10,2025

-

High Quality Rabbit Cage Double Tier Designs & Welded Wire Mesh Supplier

NewsJun.10,2025

-

Floating Fish Feed Machine - High Efficiency Floating Fish Feed Extruder for Small Scale Production

NewsJun.10,2025

-

Premium Poultry Housing Solutions Mobile & Commercial Free Range Options

NewsJun.10,2025

-

Industrial FRP Fans Corrosion-Resistant Blades & Centrifugal Systems

NewsJun.09,2025