Small Scale Fish Feed Production Equipment for Aquaculture Solutions

វិច្ឆិកា . 24, 2024 14:56 Back to list

Small Scale Fish Feed Production Equipment for Aquaculture Solutions

The Rise of Small Fish Feed Making Machines

In the aquaculture industry, the demand for quality fish feed is continually rising due to the increasing global appetite for fish and seafood. This surge has led to the development of various technologies aimed at streamlining the production process, including small fish feed making machines. These innovative machines are specifically designed to address the needs of small to medium-scale fish farming operations, providing an efficient and cost-effective solution for producing high-quality fish feed.

Understanding Fish Feed Types

Fish feed is essential for promoting healthy growth in fish and ensuring their overall wellbeing. It typically consists of proteins, vitamins, minerals, and other nutrients tailored to the specific dietary needs of various fish species. The type of feed can vary widely, ranging from pellets and flakes to granules and powders. However, one of the most popular formats is pelletized feed, which has the advantages of digestibility and reduced waste.

The Functionality of Small Fish Feed Making Machines

Small fish feed making machines offer a compact, user-friendly solution for producing fish feed at an operational scale suitable for smaller fish farms or local aquaculture businesses. These machines can produce pellets of varying sizes and compositions, catering to different species and growth stages of fish.

Typically, the process begins with grinding raw materials such as fish meal, soybean meal, corn, and various additives. The ground ingredients are then mixed to create a homogeneous blend. The mixture is extruded through the machine, forming pellets. The size and shape of the pellets can be customized by adjusting the machine’s settings.

One of the major advantages of these machines is their ability to produce floating and sinking pellets. This flexibility allows fish farmers to cater to the feeding habits of different fish species, optimizing feed consumption and growth rates.

Benefits of Using Small Fish Feed Making Machines

small fish feed making machine

2. Customization Farmers can customize the nutrient composition of the feed to suit specific fish species, ensuring optimal growth and health. This level of personalization is not typically available with mass-produced feeds.

3. Quality Control By making their own feed, farmers maintain control over the quality of ingredients used, helping to minimize the risk of contaminants and ensure the highest standards of nutrition.

4. Waste Reduction Small fish feed making machines are designed to minimize waste during production. By using precise measurements and efficient processing techniques, these machines help to ensure that almost all raw materials are converted into usable feed.

5. Scalability Many small fish feed making machines are designed to be scalable, allowing farmers to adjust their production levels as their business grows. This adaptability makes them an ideal choice for expanding fish farms.

Challenges and Considerations

While small fish feed making machines offer numerous advantages, there are challenges that users may face. Initial investment costs for the machinery can be significant, particularly for smaller operations. Additionally, farmers need to acquire knowledge regarding feed formulation and the nutritional requirements of their fish.

Moreover, it’s essential to maintain the equipment properly to ensure long-lasting performance and efficiency. Regular maintenance, cleaning, and timely repairs are critical to minimizing downtime and preventing costly disruptions in feed production.

Conclusion

As the demand for seafood continues to rise, the adoption of small fish feed making machines is likely to grow within the aquaculture sector. These machines empower fish farmers to produce high-quality feed tailored to their specific needs while promoting sustainability and cost-effectiveness. By embracing this technology, small-scale aquaculture operations can enhance their productivity, improve fish health, and contribute to the thriving global fish market. As innovation in this field progresses, we can expect to see even more advanced solutions that support the sustainable growth of aquaculture worldwide.

-

High Performance Exhaust Fan – Efficient Ventilation Solutions for Home

NewsJun.10,2025

-

High-Quality Gestation Pen for Sows Durable Mobile Pig Pen & Simple Pig Pen Solutions

NewsJun.10,2025

-

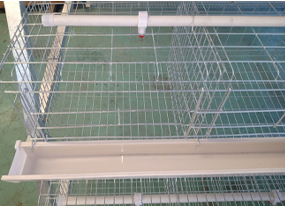

High Quality Rabbit Cage Double Tier Designs & Welded Wire Mesh Supplier

NewsJun.10,2025

-

Floating Fish Feed Machine - High Efficiency Floating Fish Feed Extruder for Small Scale Production

NewsJun.10,2025

-

Premium Poultry Housing Solutions Mobile & Commercial Free Range Options

NewsJun.10,2025

-

Industrial FRP Fans Corrosion-Resistant Blades & Centrifugal Systems

NewsJun.09,2025