High-Quality Fish Feed Extruder Machine for Efficient Aquaculture

កញ្ញា . 10, 2024 08:08 Back to list

High-Quality Fish Feed Extruder Machine for Efficient Aquaculture

Understanding Fish Feed Extruder Machines

Fish farming, also known as aquaculture, has become a crucial industry in meeting the rising global demand for seafood. To ensure healthy growth and optimal yields, aquaculture operations rely on high-quality fish feed. One of the key technologies used in producing this feed is the fish feed extruder machine. This equipment is essential in transforming raw materials into nutritious and palatable feed pellets that are suitable for various fish species.

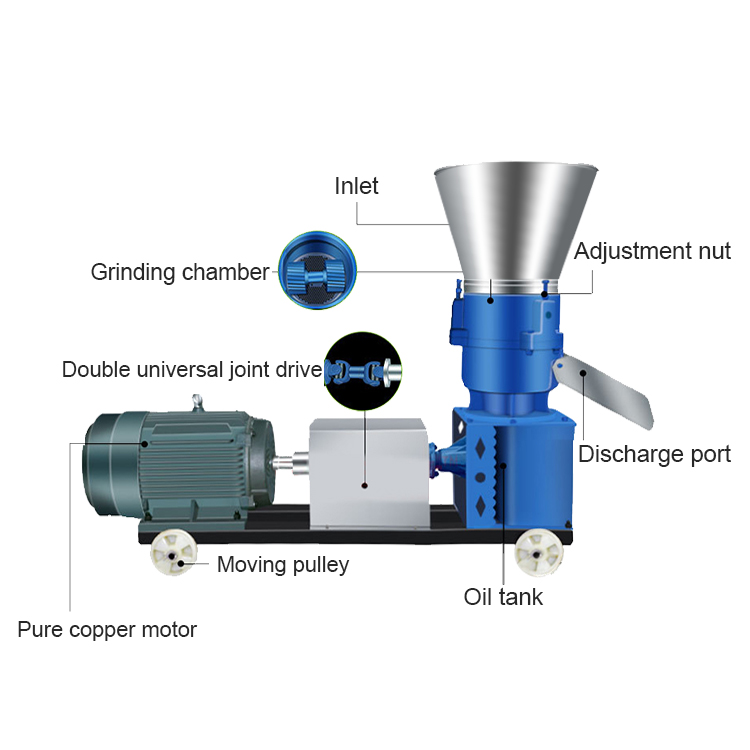

A fish feed extruder machine operates through a unique process that combines mechanical forces and thermal energy. The primary function of this machine is to cook and shape the raw ingredients into pellets. The main components of a fish feed extruder include the feeder, barrel, screw, die, and cutter. The raw materials, which can include fish meal, corn, wheat, and other nutrients, are first fed into the machine through a hopper. The feeder regulates the flow of the materials, ensuring a consistent supply to the extruder.

As the ingredients move through the barrel of the extruder, the rotating screw applies pressure and shear forces, effectively mixing and cooking the mixture. The temperature within the barrel can reach significant levels, enabling the protein in the raw materials to gelatinize, which ultimately improves the digestibility of the feed. This cooking process helps eliminate harmful pathogens, ensuring that the feed is safe for aquatic animals.

fish feed extruder machine

Once the mixture is adequately cooked, it is forced through a die at the end of the extruder. The die shapes the feed into pellets of various sizes, depending on the species of fish being targeted. After exiting the extruder, the pellets are cut to a predefined length by a cutter. This process not only produces uniform feed pellets but also enhances their buoyancy and stability in water, which is vital for feeding fish effectively.

In recent years, advancements in technology have led to the development of extruder machines that allow for greater efficiency and versatility. Modern extruders are equipped with state-of-the-art control systems, allowing operators to adjust parameters such as temperature, pressure, and moisture content to produce pellets tailored to specific fish species and dietary requirements. Additionally, some machines can incorporate functional ingredients, such as probiotics, vitamins, or minerals, boosting the nutritional value of the feed.

The benefits of using fish feed extruder machines are manifold. By facilitating the production of high-quality feed, these machines contribute to better fish growth rates, enhanced feed conversion ratios, and overall healthier aquatic populations. Moreover, the ability to formulate tailored diets for specific fish species helps aquaculture operations maximize productivity while minimizing waste.

In conclusion, fish feed extruder machines play a pivotal role in the aquaculture industry. They enable the efficient production of high-quality fish feed, addressing the nutritional needs of various fish species and enhancing the sustainability of fish farming. As technology continues to evolve, we can expect further innovations in feed production machinery, leading to even more efficient and sustainable aquaculture practices. Thus, investing in a reliable fish feed extruder machine is a wise decision for anyone looking to succeed in the fish farming business, paving the way for healthier fish and a more sustainable seafood industry.

-

Automatic Drinking Line: AI Enhanced for Peak Efficiency

NewsAug.04,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker|Broiler Farming Poultry Equipment

NewsAug.03,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Chicken Farming Automation&Durable PP Construction

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Durable PP Material&Easy Maintenance

NewsAug.03,2025

-

Top Quality Pig Farrowing Pens for Enhanced Productivity

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.

NewsAug.02,2025