feed mill hammer mill

វិច្ឆិកា . 21, 2024 12:49 Back to list

feed mill hammer mill

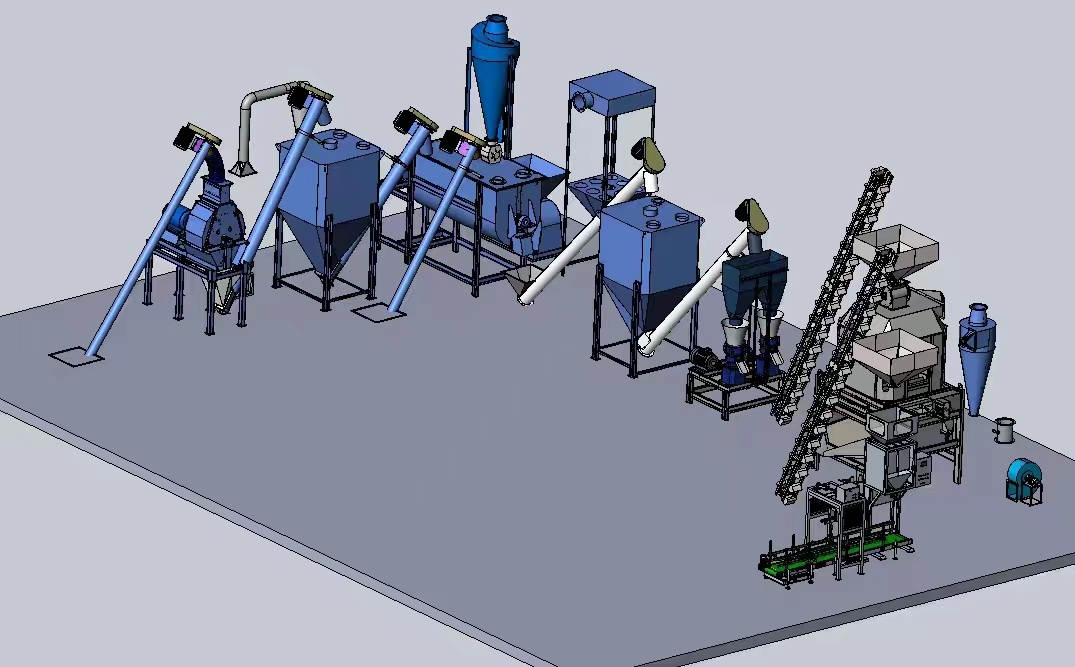

Understanding the Feed Mill Hammer Mill A Vital Component in Animal Nutrition

Feed mills are essential facilities in the agricultural sector, playing a critical role in the production of animal feed. Among the various types of machinery utilized within feed mills, the hammer mill stands out as a pivotal component that ensures feed quality and efficiency in production. This article explores the significance of hammer mills in feed milling, their operational mechanisms, benefits, and considerations for optimal use.

The Role of Hammer Mills in Feed Production

A hammer mill is a type of grinding machine used to crush and pulverize materials into smaller particles. In feed mills, it processes various raw materials such as grains, legumes, and by-products, turning them into a fine powder or meal suitable for animal consumption. The effectiveness of a feed mill largely depends on the efficiency of its hammer mill, as it directly impacts the quality of the final feed products.

How Hammer Mills Operate

Hammer mills consist of a rotating cylindrical drum with hammers attached to the outer surface. As the drum spins, the hammers strike the material entering the mill at high speeds, breaking it into smaller particles. The size of the finished product can be adjusted by changing the screen size through which the processed material passes. This ability to control particle size is crucial, as different livestock species have varying dietary requirements that necessitate specific feed particle sizes.

The process begins with the raw materials being fed into the hammer mill's hopper. Gravity draws them into the milling chamber, where the high-speed hammers crush and impact the materials. The resulting particles are expelled through the screen and collected for further processing or formulation into complete feeds.

Benefits of Using Hammer Mills

1. Efficiency and High Throughput Hammer mills are known for their high production rates. They can handle large volumes of raw materials, making them ideal for commercial feed mills. Their efficiency reduces the time and energy required for feed production.

2. Consistent Particle Size Achieving a uniform particle size is critical for animal nutrition. Consistent particle sizes ensure that animals receive balanced nutrition, enhancing their growth and overall health. Hammer mills facilitate this consistency, allowing feed manufacturers to adhere to specific nutritional guidelines.

feed mill hammer mill

3. Versatility Hammer mills can process a wide variety of ingredients, including difficult-to-manage materials like dried distillers grains, fish meal, and more. This versatility makes them an invaluable asset in creating diverse feed formulations.

4. Cost-Efficiency By reducing raw materials to smaller sizes, hammer mills enhance the digestibility of feed, which can lower feeding costs over time. The better the feed is digested, the less is required to meet the livestock's nutritional needs, leading to improved feed conversion ratios.

Considerations for Optimizing Hammer Mill Performance

To maximize the effectiveness of a hammer mill, certain factors should be taken into account

- Regular Maintenance Routine maintenance is essential for ensuring that the hammer mill operates optimally. This includes checking the hammers for wear, replacing screens as needed, and maintaining the motor and lubrication systems.

- Proper Feed Rates Overloading the hammer mill can lead to reduced efficiency and potential damage. Feed rates should be adjusted according to the specific model’s capacity and the material being processed.

- Monitoring Particle Size Regular checks on the particle size distribution can help ensure that the mill is functioning correctly and producing consistent feed quality.

Conclusion

In summary, the hammer mill is a fundamental piece of equipment in feed mills, playing a crucial role in the efficiency and quality of feed production. Understanding its operation and benefits allows feed manufacturers to optimize their processes, ultimately leading to improved animal health and growth performance. As the agricultural industry continues to evolve, investments in modern hammer mill technology will be essential for meeting the increasing demand for high-quality animal feed.

-

High Performance Exhaust Fan – Efficient Ventilation Solutions for Home

NewsJun.10,2025

-

High-Quality Gestation Pen for Sows Durable Mobile Pig Pen & Simple Pig Pen Solutions

NewsJun.10,2025

-

High Quality Rabbit Cage Double Tier Designs & Welded Wire Mesh Supplier

NewsJun.10,2025

-

Floating Fish Feed Machine - High Efficiency Floating Fish Feed Extruder for Small Scale Production

NewsJun.10,2025

-

Premium Poultry Housing Solutions Mobile & Commercial Free Range Options

NewsJun.10,2025

-

Industrial FRP Fans Corrosion-Resistant Blades & Centrifugal Systems

NewsJun.09,2025